This is out of a 1982 update seminar

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Briggs cast iron "magna matic" ignition

- Thread starter dodge trucker

- Start date

my particular engine isnt listed there. seems to have been an odd duck. I dont run this thing enough to worry about that, just know Ive seen 50 yo engines running original points and still good....

I might have a job this spring/ summer where it will get run the snot out of for a couple of days.... that might help that it's gonna actually get a few tanks of gas run out of it all at once.... I know sitting doesnt help any of them

I might have a job this spring/ summer where it will get run the snot out of for a couple of days.... that might help that it's gonna actually get a few tanks of gas run out of it all at once.... I know sitting doesnt help any of them

they're cheap, readily available and fit in places other files etc don't... The first time today I ran a strip of actual emery cloth in them, followed by a business card then followed by a squirt of electrical contact cleaner before I ever went thru all the rest I did before it finally decided to run.Only thig I ever use on points is a point file or 400 grit wet-or-dry sandpaper. In my estimation, finger nail file boards are way to course and scratch the points doing more damage than good. Just my thouights on the mater.

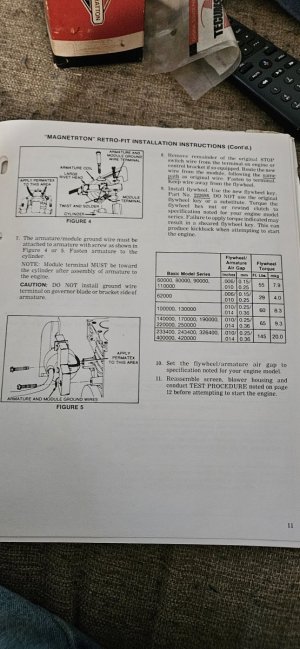

Interesting it doesn't mention sending the flywheel back andhaving it remagnatized. Somebody posted not too long ago they still did it. What did theyrefer to the ignitionsystem that was being replaced with the magnatron?This is out of a 1982 update seminar

Maybe you're right but I've never heard the later system referred to as that. I can't find what they called it. When Briggs first went with the number series engines they used this ignition system on the models 9, 14, 19, and 23. The 23A also used it. The part shown on the craqnk is the magnetic rotor. This is the system I always heard referred to as magna=matic. The coil was held to the body by steel clips. They were bad for loosing the ground connection where the coil sits and then no spark. The 23C and D used the later 3 legged coil like the 4th pic. Those coils weren't a direct replacement to the magnetron. You needed the 2 legged coil for that. (5th pic) The 6th pic shows the magnetron coil with the built in trigger..Huh. I thought that all cast iron engines with the points in a box on the side of the block were considered "magna matic".

Attachments

I finally found one of my old Briggs books. This one barely mentions my engine series, buried within the text. Yeah they show "magna matic" separately they just refer to what I have as " cast iron external points models" after the magna matic" in the ignition section

Yes Doug, those 1st couple pics is magna-matic like in my model 14. I removed the coil and portion of metal that passed through it. There was room behind flywheel for a frame mounted type 6v motorcycle coil to sit atop the legs so I drilled and tapped the legs to mount the coil. The coil had one wire grounded, so ran other wire to the points. I really had no idea if it would work but it did, and the engine was alive and well again. As you know, magna-matic coils are NLA, but there is definitely a work-around. Pretty sure the coil I used was off a Honda CT70 or similar model bike.

Those CT70s are priced as if they're made of gold these days