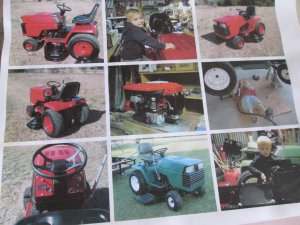

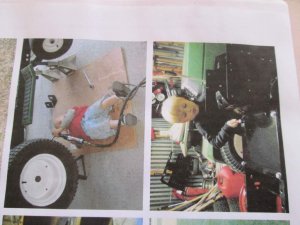

So RED hits 30 this year. I purchased him 9/11/2009 for $100.00. He has done well for me, and I usually do a Winter re-fresh every couple years. I have a new main mower (Craftsman Pro) and a backup (BOH) so I am thinking of a more detailed update on RED.

I know what RED's main issues are and have the parts on-hand as I ordered them many Month ago.

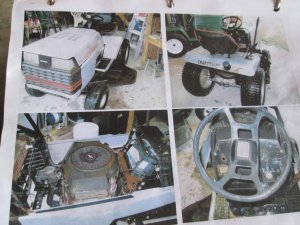

Tear down has begun, and two of the issues are almost obvious. Oil leak and sloppy steering. Parts are on-hand to address these issues. Also a new ring set for the 42A707 18 HP Briggs

Stopping point for the evening. I need to pressure wash this before I go further, hard to see the bolt heads underneath.

I know what RED's main issues are and have the parts on-hand as I ordered them many Month ago.

Tear down has begun, and two of the issues are almost obvious. Oil leak and sloppy steering. Parts are on-hand to address these issues. Also a new ring set for the 42A707 18 HP Briggs

Stopping point for the evening. I need to pressure wash this before I go further, hard to see the bolt heads underneath.