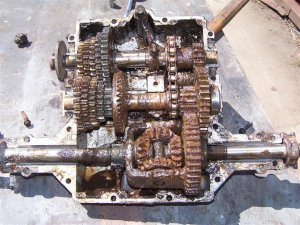

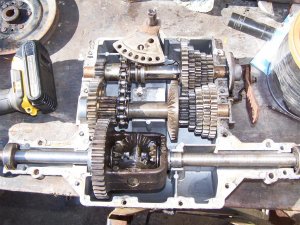

This fall a friend brought this Craftsman II to my shop and gave it to me, so about a week ago I got it into the shop and started to check it out, its been sitting for years he got disgusted with it cause he couldn't get it to cut even. Anyway I worked on the engine first if I couldn't get it running it was a junker, put a shot of gas in the carb cranked and it started right off so I checked the gas tank it was clean as could be put so gas in it and cranked nothing squeeze a shot of gas into the carb it would but as soon as the was gone nothing so I removed the carb and cleaned it was pretty clean inside reinstalled it after finally figuring out B&S throttle/coke set up cranked it it started and ran fair, after tuning got it to run better but not right at idle removed the idle screw shot a good shot of carb cleaner in got the air hose gave it a good blast carb cleaner came out all over reinstalled the idle screw cranked it up and it runs perfect, this is a 12 HP B&S IC with cast iron cylinder liners good engines, So now on the other things removed the deck what a deal that is washed it down some with gas too cold for power washing drove it around shifts into all the forward gears good but will not go into reverse. Removed the seat and fenders to see the shift linkage, when trying to go to reverse the shift lever just flexes put a large cresent wrench on the shifter mech and can get it into reverse worked it in and out many times thinking it would loosen up and it seemed to but this morning when I tried it no go. This is a Peerless 802 I think where the shifter moves to the right for reverse and to the left for the 5 forward speed, Does anyone know antthing about these transaxles and there shifting as to what could be causing it to not want to go into reveres?