Please be aware this information is presented AS IS – USE AT YOUR OWN RISK AND EXPENSE

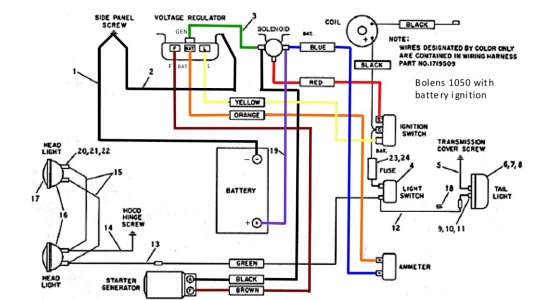

Please note some measurements stated are what were observed while working on a Bolens 1050 tractor with a starter generator 1101970 – other Delco Remy starter generators may be different.

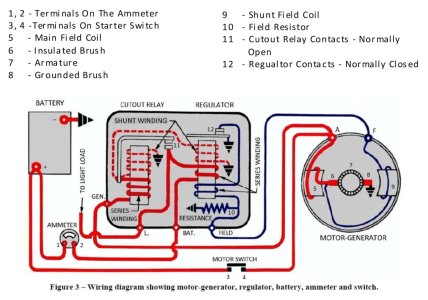

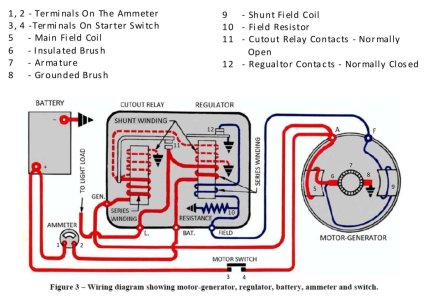

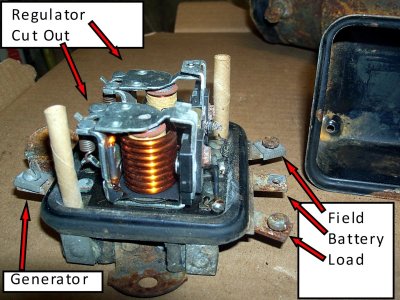

It is my hope that this article will provide the reader with a basic understanding of how a 12 volt Delco Remy Starter / Generator works on a garden tractor application to start an engine and also to charge the battery back up once the engine is running. This information should make it easier for the reader to diagnose and troubleshoot a charging or starting problem and at the same time provide a working knowledge of the system components involved. I will attempt to keep the technical part of the learning process to a simple level that most people with some basic knowledge of electricity can understand.

For those following along if I post something that you do not understand feel free to ask and I will try and answer any questions as best I can. I am not an electrical expert and if I post information you feel is wrong please advise as this is how we all learn.

For those who want a deeper working knowledge they can refer to the Delco Remy service bulletin IMG-150 which I will also attach as a pdf copy.

Please note some measurements stated are what were observed while working on a Bolens 1050 tractor with a starter generator 1101970 – other Delco Remy starter generators may be different.

It is my hope that this article will provide the reader with a basic understanding of how a 12 volt Delco Remy Starter / Generator works on a garden tractor application to start an engine and also to charge the battery back up once the engine is running. This information should make it easier for the reader to diagnose and troubleshoot a charging or starting problem and at the same time provide a working knowledge of the system components involved. I will attempt to keep the technical part of the learning process to a simple level that most people with some basic knowledge of electricity can understand.

For those following along if I post something that you do not understand feel free to ask and I will try and answer any questions as best I can. I am not an electrical expert and if I post information you feel is wrong please advise as this is how we all learn.

For those who want a deeper working knowledge they can refer to the Delco Remy service bulletin IMG-150 which I will also attach as a pdf copy.