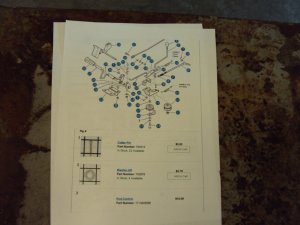

Couple of weeks back I got ahold of a JD100 round fender. No engine and a few parts missing.so decided I would like to have a 100 round fender with a hydrostatic Transmission. Got a rear end out of a Simplicity and off we go. took the 100 apart and the rear end out of the simplicity and am going to fit the two together. I didn't take pics before I tore the 100 down, (sorry but I am bad about doing a project without thinking to take pics., will try to do better this time.) Here area couple of pics of what a 100 looks like.

These two pics of are a 100 I restored a couple of years ago. The next pics are of what I am working with this time.

For some reason Gaby thinks she should be in the pic.

Next pic is of the simplicity rear end that will be going underneath the 100.

I will try to take more pics as the project proceeds.

These two pics of are a 100 I restored a couple of years ago. The next pics are of what I am working with this time.

For some reason Gaby thinks she should be in the pic.

Next pic is of the simplicity rear end that will be going underneath the 100.

I will try to take more pics as the project proceeds.