Kinda like Jeff Dunham’s terrorist puppet achmed... except not “o holy crap I think I blew my foot off”

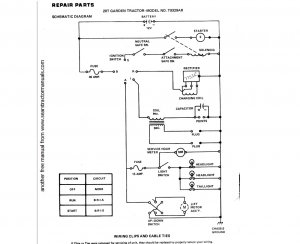

Anyhow! Roper tractor nearly burnt up me earlier. Hot wire to key grounded out on frame and burnt off, melted coating and burnt a bunch of other wires under the dashboard. How big of a project am I in for?

If anyone has any advice about electrical on Sears machines I’m interested in hearing it. Kinda sucks having roper out of commission, it’s my “go to” given its weight and gearing

I’ll add pics when I get home

Anyhow! Roper tractor nearly burnt up me earlier. Hot wire to key grounded out on frame and burnt off, melted coating and burnt a bunch of other wires under the dashboard. How big of a project am I in for?

If anyone has any advice about electrical on Sears machines I’m interested in hearing it. Kinda sucks having roper out of commission, it’s my “go to” given its weight and gearing

I’ll add pics when I get home