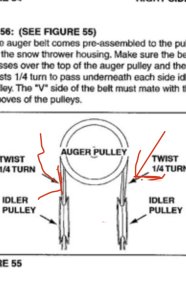

Went into the shop this afternoon to check the new notched belt for fit and wear NOT good the darn belt flipped over and was running upside down over the blower / auger drive, removed the blower from the GT5000 looked it over and over thought maybe the idler V pulley was out of alignment on the RH side added some washers to move the idler reinstalled started the tractor engaged the PTO ran about 2 minutes could see that it had made a half turn stopped removed the blower thought I'd try a Kevlar "A" belt installed the blower ran it 5 minutes all looked ok went outside and blew snow for 10 minutes belt is in place but started slipping in heavier snow will go back and add so tension to the belt adjusting idler.

I'm now wondering if the other belts were rolling over and running on the backside causing them to fail in about 10 hrs

I'm now wondering if the other belts were rolling over and running on the backside causing them to fail in about 10 hrs