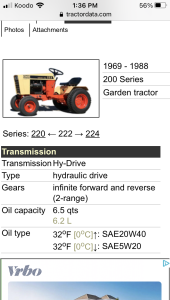

Got the Case 222 out from the storage area and into the shop this afternoon, need to do some engine work it starts and runs but when I engage the deck is bogs down and backfire thru the carb and spits oil out the breather lots of oil. just running around with no deck it runs good, anyway I thought maybe the valves needed setting or are bad, I had set the valves last summer but thought maybe I messed it up but no the setting are fine the intake valve really needs to be replaced and after getting the head off there was oil up on the piston so it need rings and I know it has a lot of blow by / crankcase pressure. So I have to decide should I just put new rings in or go further.

Noel have a question how hard is it to get the engine out of a Case?

Noel have a question how hard is it to get the engine out of a Case?