As I explore greater capabilities for my GT, and with limited experience with tractors (though increasing all the time), I decided to purchase an inexpensive box blade/ rear blade implement. Like the Johnny Bucket JR purchase I made with the tractor in 2017, I figured I would find out how many uses there are for the box blade after I buy it and start using it.

The two most common box blades I could find were Brinly Hardy, and Agri-Fab, in the Garden Tractor market for Sleeve Hitch attachment. They have some similar or same components between them but offer some differences in their package. Price range $100- $150. I realize many of you in this forum have 3 point on heavy GT's with plenty of experience, but for those like myself or if making an overall purchase decision, I figured I'd show what you get in the box, the minor modifications I did to it, and overall thoughts after using the box blade a few times.

I'm interested in thoughts from the 3-point experience too, did you start here also? was it an Agri-Fab? or Brinly Hardy? Also, tips for gaining skill with this thing in general.

I'm still thinking, if someone is buying a GT with implement use thoughts for the future, a bucket is still by far the most valuable tool. A bucket can do a little of everything, the SUV of implements, not the most specialized in much but can get many different jobs done as an all-in-one package.

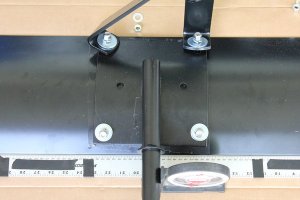

Between the two brands offered, the reason I went with the Brinly Hardy was because it was available to purchase when I made the trip to a far away local Northern Tool. The Agri-Fab had a back-order on it. It was that simple. So here is what I bought,

More in the next post,

The two most common box blades I could find were Brinly Hardy, and Agri-Fab, in the Garden Tractor market for Sleeve Hitch attachment. They have some similar or same components between them but offer some differences in their package. Price range $100- $150. I realize many of you in this forum have 3 point on heavy GT's with plenty of experience, but for those like myself or if making an overall purchase decision, I figured I'd show what you get in the box, the minor modifications I did to it, and overall thoughts after using the box blade a few times.

I'm interested in thoughts from the 3-point experience too, did you start here also? was it an Agri-Fab? or Brinly Hardy? Also, tips for gaining skill with this thing in general.

I'm still thinking, if someone is buying a GT with implement use thoughts for the future, a bucket is still by far the most valuable tool. A bucket can do a little of everything, the SUV of implements, not the most specialized in much but can get many different jobs done as an all-in-one package.

Between the two brands offered, the reason I went with the Brinly Hardy was because it was available to purchase when I made the trip to a far away local Northern Tool. The Agri-Fab had a back-order on it. It was that simple. So here is what I bought,

More in the next post,