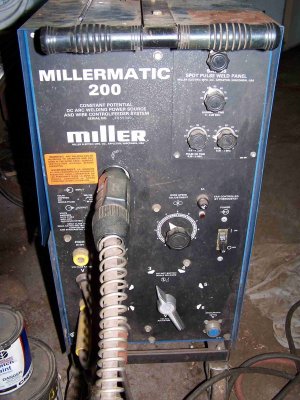

I used the MIG welder last week and it worked fine. Today I went to use it and it won't turn on. The on/off switch flops around when in the on position, so I think it's a bad switch. In the off position it snaps in with no slop and as I recall that's how the on position always used to be. Anyway I ordered a switch and it should be in Monday. Hope thats the problem.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MillerMatic 200 MIG welder died

- Thread starter cjet69

- Start date

Definitely worth fixing vs taking a chance on a newer (cheaper manufactured) probably piece o crap

I've used a 200. Very nice welding machine. Ours had a spotweld feature on it which was rarely uesd..I sure hope that's the problem. Some of the other stuff can get expensive quickly.

It's pretty common on these bigger welders

What is pretty common on these welders?It's pretty common on these bigger welders

I have a millermatic 185 that I bought new back around 98, hasn't missed a beat. I have replaced a liner or 2 is all in those years.

They revamped their line, I believe my 185 is what they now call their "211". Id like to find a spool gun for it so I can experiment with some aluminum. When I bought it I was debating between this one and the big boy 250 (we have that one at work) and what made the decision was that the 185 was pre wired with the plug for the spool gun, the 250 wasn't/ not knowing if Id ever get one at least the machine was capable.

Id previously burnt out 2 110 powered rinky dink mig welders and decided that my 3rd one would be 220v which hopefully meant that I wouldn't have to buy another one in my lifetime. So far that's been true.

Though I've used a few newer (than what I had) 110v units that seem much better than the 2 that I had.

I sometimes wish I had the "spot weld" setting, as the newer versions of my unit, do.but no, I ain't buying another welder just to get that.

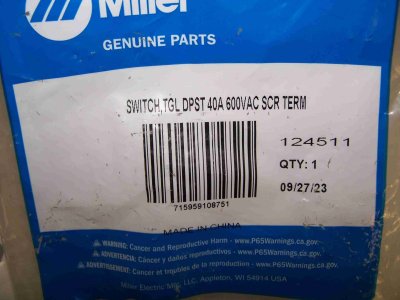

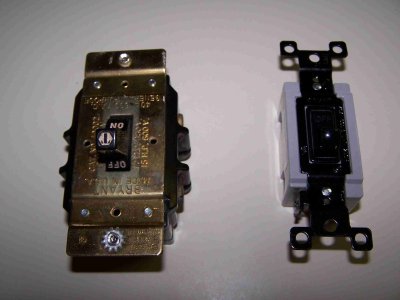

The new switch arrived today. Its much smaller but has the same rating. Hope it holds up OK. The switches are set up different also. On the old switch the top terminals, R/L were paired up and the bottom terminals were paired up. The new switch the terminals are right side top and bottom and left side top and bottom. If you don't hook them up right the circuit breaker will trip. Don't ask how I know. I had to tear the old switch apart to find which terminals were paired together because I couldn't get continuity through the old switch. Once I figured that out without cooking anything I got it wired correctly and the welder is now back in operation. This machine has the spot/pulse feature also.

Attachments

-

100_5664-m.jpg156.3 KB · Views: 6

100_5664-m.jpg156.3 KB · Views: 6 -

100_5665-m.jpg187 KB · Views: 5

100_5665-m.jpg187 KB · Views: 5 -

100_5669-m.jpg133 KB · Views: 5

100_5669-m.jpg133 KB · Views: 5 -

100_5670-m.jpg103.3 KB · Views: 6

100_5670-m.jpg103.3 KB · Views: 6 -

100_5671-m.jpg100.4 KB · Views: 5

100_5671-m.jpg100.4 KB · Views: 5 -

100_5678-m.jpg225.5 KB · Views: 6

100_5678-m.jpg225.5 KB · Views: 6 -

100_5679-m.jpg205 KB · Views: 5

100_5679-m.jpg205 KB · Views: 5 -

100_5680-m.jpg227.9 KB · Views: 5

100_5680-m.jpg227.9 KB · Views: 5 -

100_5681-m.jpg119.6 KB · Views: 7

100_5681-m.jpg119.6 KB · Views: 7

Thats what I was thinking. Now that I have the old switch out, I can read the part number. May want to get another heavy duty switch to have on hand or just swap it out.That new one looks like a light switch, CJet! Glad you got the machine back welding again!

DAC

Played around with the old switch and found the plastic slide that runs the contacts was stuck. Straightened it out and it slides smoothly again. Couldn't get it to hang up no matter how hard I tried. The contacts look great, so I put it back together and it is working just fine. The switch doesn't flop around in the on position like it did before. Feels nice and solid like it used to. Maybe I will just put it back in and see how it works.