I picked this up some time ago at a garage sale and haven't had the project to use it.

So now begins the learning process.

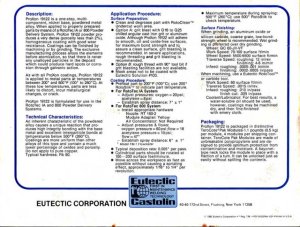

After much searching on the web it appears the company that produced the consumables that came with my kit no longer exists.

I am now in the process of trying to find suitable replacement materials. I have powders to play with but since I have not yet found a sure source of replacement powder I am reluctant to start experimenting thinking that if the learning curve is to steep I may not have enough powder left to finish the job.

I would appreciate any input. I have the Permacool Bond powder and maybe 2 lbs of Permacool Solid PM1209 and some instructions how to use it. I do not have any information to tell me exactly what this powder was engineered for. I have had the torch lit and it appears to function fine.

My plan is to build up this shaft.

![20211211_144712[1].jpg 20211211_144712[1].jpg](https://tractorfanatics.com/data/attachments/45/45764-37c83609a0116763e0b2524e1d773b18.jpg?hash=N8g2CaARZ2)

I have a bearing and seal surface on one side.

![20211211_144553[1].jpg 20211211_144553[1].jpg](https://tractorfanatics.com/data/attachments/45/45765-5825fd9480037de7d307a561aa8df9e8.jpg?hash=WCX9lIADfe)

And just a bearing surface on the other.

![20211211_144613[1].jpg 20211211_144613[1].jpg](https://tractorfanatics.com/data/attachments/45/45767-44c4827c94b909ecef43a44c4d26fcde.jpg?hash=RMSCfJS5Ce)

Couldn't get a proper focus on that one.

I have found videos of this torch at work but none that gave information about the powders being used. I have also found videos of other flame spray processes nost of which seem to be much higher temp. The instructions I have say to preheat the part to 200F and never let it exceed 500F. Any help or comments appreciated.

Don

So now begins the learning process.

After much searching on the web it appears the company that produced the consumables that came with my kit no longer exists.

I am now in the process of trying to find suitable replacement materials. I have powders to play with but since I have not yet found a sure source of replacement powder I am reluctant to start experimenting thinking that if the learning curve is to steep I may not have enough powder left to finish the job.

I would appreciate any input. I have the Permacool Bond powder and maybe 2 lbs of Permacool Solid PM1209 and some instructions how to use it. I do not have any information to tell me exactly what this powder was engineered for. I have had the torch lit and it appears to function fine.

My plan is to build up this shaft.

![20211211_144712[1].jpg 20211211_144712[1].jpg](https://tractorfanatics.com/data/attachments/45/45764-37c83609a0116763e0b2524e1d773b18.jpg?hash=N8g2CaARZ2)

I have a bearing and seal surface on one side.

![20211211_144553[1].jpg 20211211_144553[1].jpg](https://tractorfanatics.com/data/attachments/45/45765-5825fd9480037de7d307a561aa8df9e8.jpg?hash=WCX9lIADfe)

And just a bearing surface on the other.

![20211211_144613[1].jpg 20211211_144613[1].jpg](https://tractorfanatics.com/data/attachments/45/45767-44c4827c94b909ecef43a44c4d26fcde.jpg?hash=RMSCfJS5Ce)

Couldn't get a proper focus on that one.

I have found videos of this torch at work but none that gave information about the powders being used. I have also found videos of other flame spray processes nost of which seem to be much higher temp. The instructions I have say to preheat the part to 200F and never let it exceed 500F. Any help or comments appreciated.

Don

![20211211_174601[1].jpg 20211211_174601[1].jpg](https://tractorfanatics.com/data/attachments/45/45775-62af7d282698a86bf69a84bff3cde14b.jpg?hash=Yq99KCaYqG)