You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beware of Husqvarna Garden Tractors!

- Thread starter GT48DXLS

- Start date

I just noticed that this member hasn't been on since that post. And that post was their only one.

Hope they got resolution

That or he's one of the members having issue getting back on the site.

Willie I think you missed your calling. That was good detective work!

I have to give the guy credit, at least he is keeping his cool under the intense grilling some of those people are giving him. And he has gone way out of his way to explain every detail to the members there and they still aren't cutting him much slack.

Thinking it boils down to this, if the dealer said that the machine was capable of doing a required task and it failed doing that then the machine was misrepresented. I'm not saying that Husqvarna is at fault but the dealer sure could be.

I have to give the guy credit, at least he is keeping his cool under the intense grilling some of those people are giving him. And he has gone way out of his way to explain every detail to the members there and they still aren't cutting him much slack.

Thinking it boils down to this, if the dealer said that the machine was capable of doing a required task and it failed doing that then the machine was misrepresented. I'm not saying that Husqvarna is at fault but the dealer sure could be.

man, this guy has a load on his...

Wow!

man, this guy has a load on his...

That video is crazy. There is no way that tractor can handle that bucket for long before imploding. My god, what was he thinking? There have been heavier built tractors than his that have been wrecked with a FEL. It's only a matter of time.

Actually I did workman's comp investigations for a while, but this was simply google foo. I figured it he posted her once and vanished he may have done it elsewhere. That was the only replies I found from him, although it was pretty in depth.Willie I think you missed your calling. That was good detective work!

.

1st I want to give one big THANK YOU to all the members here that commented and to Cvans for reaching out and asking what came of all this mess. I appreciate all the support.

There is so much worth updating you all on, not all favorable. Too much really in one sitting.

I do apologize for starting this and not responding at least regular, I do hope to try and put this event out there in order that it causes someone in my position to ask questions they might not have asked or give thought as to why the quality brands out there might charge more for their product instead of thinking it's just a name. I've learned much in this process. There have been some very knowledgeable and generous people with there time.

The second thing I hoped to accomplish is this, If there is someone out there in this same position with all that is invested and a new machine that has been reduced to expensive lawn furniture with little to no support, there is hope, and not because I'm anybody. I am going to start the new build in a way that you will see my mistakes and success. The purpose of this is to have someone say "if he can do it" "so can I" or even "I can do it better".

This is the plan but I'm not one of those Google Gurus, in fact I don't have a smart phone by choice (so I'm not linked), I visit email unless purposed aprrox once a week. I did start a few accounts to try and get the word out but generally prefer working outside. We do live in the computer age and I try.

There is so much worth updating you all on, not all favorable. Too much really in one sitting.

I do apologize for starting this and not responding at least regular, I do hope to try and put this event out there in order that it causes someone in my position to ask questions they might not have asked or give thought as to why the quality brands out there might charge more for their product instead of thinking it's just a name. I've learned much in this process. There have been some very knowledgeable and generous people with there time.

The second thing I hoped to accomplish is this, If there is someone out there in this same position with all that is invested and a new machine that has been reduced to expensive lawn furniture with little to no support, there is hope, and not because I'm anybody. I am going to start the new build in a way that you will see my mistakes and success. The purpose of this is to have someone say "if he can do it" "so can I" or even "I can do it better".

This is the plan but I'm not one of those Google Gurus, in fact I don't have a smart phone by choice (so I'm not linked), I visit email unless purposed aprrox once a week. I did start a few accounts to try and get the word out but generally prefer working outside. We do live in the computer age and I try.

Before I start the updates I want to point out a couple things so they make sense.

When I said “multiple times before” in reference to use of the scoop, more specifically approx 35-38 hrs of use, near as we can figure. If anyone is thinking about one of these scoops from the many manufacturers, other than the basic structural requirements (I will go into some of this in the build), I’ll pass on that it was useless with the stock 2ply turf tires and weight of the tractor. (I want to point out I think soil makes a difference too).

Each time I added another piece (including the Lugs that were recommended by the Dealer) of weight and traction the tractor came to life and was more usable. The weights and torque, load, placed on the tractor were still under the specs of Tuff Torq K66 with manual (electric switch) locking axle and inline with the recommendations of the Dealer and the other competitive brands to include Craftsman.

As a note, The Dealer is also the one that installed the Lugs they recommended on the extra Husqvarna rear wheels I bought through the Dealer so I could easily change from turf to lugs depending on the work. They commented to me that first month that no-one has ever done that before, yet it made sense to me. This is also an important fact when weighing against Husqvarna’s laughable response.

Consider this second bit of info too;

I believe it comes down to a certain measurement of wheel torque being applied to the ground for a certain measure of work with the given dimensions of the scoop including the forces against the tractor at any given time in this process. Am I making sense? I’m sure others out there can word this better.

Without going into too much detail, a muscle car with say a 500hp, (1hp being a measure of 550 lbs being lifted 1ft in 1 sec, or there about) 500ft lbs of torque motor (torque being the measure of lbs in ft per sec of work or actual force applied, or there about) that is doing the classic burnout or exhibition of pure force on pavement, if connected to a cable type scale from the rear to a fixed location might read a few pounds in that moment, not 500lbs. The reason for the discrepancy is that the wheels in that moment are not applying the 500ft lbs of maximum torque the motor is capable of developing because the wheels are spinning and no force is actually measurable against that fixed location.

I’m trying to point out these facts I believe are applicable to understanding why I believe some of the more pertinent answers from Husqvarna are to put it kindly, laughable! Or just plain insulting to their customers, because I’m just one of many.

Husqvarna has compelled me in their complete lack of respect, and deceptive practices to put the effort (I’m a “quiet professional” in my field of work) into dissecting, analyzing, collecting, and readying for public view, everything I can about their business practice surrounding their Garden Tractors that aren’t, and how their Garden Tractor is actually built.

Lets be clear, I will not by my own hand remove this statement, ever.

I do not want any money from Husqvarna, in any capacity, from any representatives, period. Their is nothing that husqvarna can ever do for me at this point, but to come clean, apologize, and rethink their current business model that is unsustainable. In other words Husqvarna, KEEP YOUR WORD. I do know that there are Husqvarna employees on these forums, don’t know which specifically because they have been too afraid to come out in the open (being honest as I have, but I have some ideas) and have an honest discussion of their official warranty denial response. They refuse to talk to me.

If Husqvarna called me up and said let us comp your new frame (reimburse me) I would deny it and ask for public apology for myself and anyone else who bought a GT/TS from them thinking they would honor the warranty when using it as a Garden Tractor. Selling a customer on a warranty is a powerful way to close a sale with a customer on the fence.

I would also make all conversations public to include the ones they want private (because I will not agree to any non-disclosure agreements, but private names will be kept private), as proof, I will post the response I was given (without my colorful responses to it). I will also give the response I was given in a separate update with my colorful responses (admittedly not making me look great necessarily but for being honest). My credibility both private and professional is my identity, and as things go is most important. I can make mistakes, get information wrong, but can also be held accountable voluntarily, unlike Husqvarna. This is my Statement, done.

When I said “multiple times before” in reference to use of the scoop, more specifically approx 35-38 hrs of use, near as we can figure. If anyone is thinking about one of these scoops from the many manufacturers, other than the basic structural requirements (I will go into some of this in the build), I’ll pass on that it was useless with the stock 2ply turf tires and weight of the tractor. (I want to point out I think soil makes a difference too).

Each time I added another piece (including the Lugs that were recommended by the Dealer) of weight and traction the tractor came to life and was more usable. The weights and torque, load, placed on the tractor were still under the specs of Tuff Torq K66 with manual (electric switch) locking axle and inline with the recommendations of the Dealer and the other competitive brands to include Craftsman.

As a note, The Dealer is also the one that installed the Lugs they recommended on the extra Husqvarna rear wheels I bought through the Dealer so I could easily change from turf to lugs depending on the work. They commented to me that first month that no-one has ever done that before, yet it made sense to me. This is also an important fact when weighing against Husqvarna’s laughable response.

Consider this second bit of info too;

I believe it comes down to a certain measurement of wheel torque being applied to the ground for a certain measure of work with the given dimensions of the scoop including the forces against the tractor at any given time in this process. Am I making sense? I’m sure others out there can word this better.

Without going into too much detail, a muscle car with say a 500hp, (1hp being a measure of 550 lbs being lifted 1ft in 1 sec, or there about) 500ft lbs of torque motor (torque being the measure of lbs in ft per sec of work or actual force applied, or there about) that is doing the classic burnout or exhibition of pure force on pavement, if connected to a cable type scale from the rear to a fixed location might read a few pounds in that moment, not 500lbs. The reason for the discrepancy is that the wheels in that moment are not applying the 500ft lbs of maximum torque the motor is capable of developing because the wheels are spinning and no force is actually measurable against that fixed location.

I’m trying to point out these facts I believe are applicable to understanding why I believe some of the more pertinent answers from Husqvarna are to put it kindly, laughable! Or just plain insulting to their customers, because I’m just one of many.

Husqvarna has compelled me in their complete lack of respect, and deceptive practices to put the effort (I’m a “quiet professional” in my field of work) into dissecting, analyzing, collecting, and readying for public view, everything I can about their business practice surrounding their Garden Tractors that aren’t, and how their Garden Tractor is actually built.

Lets be clear, I will not by my own hand remove this statement, ever.

I do not want any money from Husqvarna, in any capacity, from any representatives, period. Their is nothing that husqvarna can ever do for me at this point, but to come clean, apologize, and rethink their current business model that is unsustainable. In other words Husqvarna, KEEP YOUR WORD. I do know that there are Husqvarna employees on these forums, don’t know which specifically because they have been too afraid to come out in the open (being honest as I have, but I have some ideas) and have an honest discussion of their official warranty denial response. They refuse to talk to me.

If Husqvarna called me up and said let us comp your new frame (reimburse me) I would deny it and ask for public apology for myself and anyone else who bought a GT/TS from them thinking they would honor the warranty when using it as a Garden Tractor. Selling a customer on a warranty is a powerful way to close a sale with a customer on the fence.

I would also make all conversations public to include the ones they want private (because I will not agree to any non-disclosure agreements, but private names will be kept private), as proof, I will post the response I was given (without my colorful responses to it). I will also give the response I was given in a separate update with my colorful responses (admittedly not making me look great necessarily but for being honest). My credibility both private and professional is my identity, and as things go is most important. I can make mistakes, get information wrong, but can also be held accountable voluntarily, unlike Husqvarna. This is my Statement, done.

Update,

The Dealer did not expect me to do everything on my own, to include prove he lied to my wife when trying to rip us off $500 to $600 dollars to conveniently repair and deny the warranty which would not have paid as much money to the Dealer.

The Dealer said it would cost an extra $95 in a special bulk freight shipment charge to get the new frame. So according to him it was going to require a big truck because it was too heavy, bulky etc. for standard ups freight. I've had that before with a new appliance, I'm familiar.

The truth,

I ordered the new frame just before receiving Husqvarna's response, for $148.00 plus $13.00 and change for UPS ground shipping from a Husqvarna Dealer 5 or 6 hrs south in Miami FL. I received the frame from my regular UPS driver 5 days later. I will post pics.

I blame Husqvarna Corporate, (the Dealer is responsible for his part too, they are partners) because, the ads being used, sales aids, and redirected support all are from them. Corporate. The Dealer is the "authorized representative" for Husqvarna in all things related to the sale, service, warranty work, warranty evaluation, and after sale accessory recommendations and support. This is what I got from Husqvarna when they redirected me to the Dealer.

Husqvarna started talking with me because I insisted they do (I was willing to risk the warranty at this time), I refused to talk again with the Dealer that was hostile to my Wife (my Wife is my authorized representative for me in all things, so they were hostile to me). I also refuse to take my tractor to the next town where the closest alt Dealer was because at that point I was not going to be subject to this way of business again. I told them "fix it".

The total package weight is 32lbs as listed on the label. The actual chassis weight is 26lbs even. It's 12ga as measured with micrometer including the e-coat in that measurement and confirmed by the Fabricator I hired. Anyone can go on line with UPS, and look at the weight maximum and dimensions in inches or metric for standard ground shipping, not even close, but I gave these dimensions to back this up and....

As an interesting note. My old 2011 Ariens with bs intek 17.5hp motor, 6-speed (Tuff Torq, I resealed once) $900 HD grass cutter special has the same pan style frame, the same gauge of steel, The same height, the same width, (I was able to bolt the front bumper from the Husqvarna GT/TS to the front of the Ariens just to demonstrate to my Wife) as the "Heavy duty garden tractor with unbeaten capabilities in its class" (Husqvarna's description on their page as of today's date). Laughable.

By the way my old grass cutter is not much to look at, but is still getting the job done to include in the past (this is what blew out the seals) it delivered 700lbs to 1000lbs of sand (I had to remove a section 35ft by 35 ft 18 inches and put it back, not the same sand of course!) from the front drain field to the back when it was Septic Appocalips 2016.).

The Dealer did not expect me to do everything on my own, to include prove he lied to my wife when trying to rip us off $500 to $600 dollars to conveniently repair and deny the warranty which would not have paid as much money to the Dealer.

The Dealer said it would cost an extra $95 in a special bulk freight shipment charge to get the new frame. So according to him it was going to require a big truck because it was too heavy, bulky etc. for standard ups freight. I've had that before with a new appliance, I'm familiar.

The truth,

I ordered the new frame just before receiving Husqvarna's response, for $148.00 plus $13.00 and change for UPS ground shipping from a Husqvarna Dealer 5 or 6 hrs south in Miami FL. I received the frame from my regular UPS driver 5 days later. I will post pics.

I blame Husqvarna Corporate, (the Dealer is responsible for his part too, they are partners) because, the ads being used, sales aids, and redirected support all are from them. Corporate. The Dealer is the "authorized representative" for Husqvarna in all things related to the sale, service, warranty work, warranty evaluation, and after sale accessory recommendations and support. This is what I got from Husqvarna when they redirected me to the Dealer.

Husqvarna started talking with me because I insisted they do (I was willing to risk the warranty at this time), I refused to talk again with the Dealer that was hostile to my Wife (my Wife is my authorized representative for me in all things, so they were hostile to me). I also refuse to take my tractor to the next town where the closest alt Dealer was because at that point I was not going to be subject to this way of business again. I told them "fix it".

The total package weight is 32lbs as listed on the label. The actual chassis weight is 26lbs even. It's 12ga as measured with micrometer including the e-coat in that measurement and confirmed by the Fabricator I hired. Anyone can go on line with UPS, and look at the weight maximum and dimensions in inches or metric for standard ground shipping, not even close, but I gave these dimensions to back this up and....

As an interesting note. My old 2011 Ariens with bs intek 17.5hp motor, 6-speed (Tuff Torq, I resealed once) $900 HD grass cutter special has the same pan style frame, the same gauge of steel, The same height, the same width, (I was able to bolt the front bumper from the Husqvarna GT/TS to the front of the Ariens just to demonstrate to my Wife) as the "Heavy duty garden tractor with unbeaten capabilities in its class" (Husqvarna's description on their page as of today's date). Laughable.

By the way my old grass cutter is not much to look at, but is still getting the job done to include in the past (this is what blew out the seals) it delivered 700lbs to 1000lbs of sand (I had to remove a section 35ft by 35 ft 18 inches and put it back, not the same sand of course!) from the front drain field to the back when it was Septic Appocalips 2016.).

Attachments

Update,

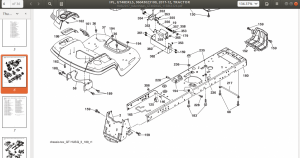

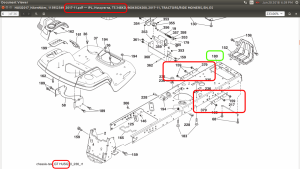

Their newly introduced Garden Tractor line (identical to the GT48DXLS except the "improves"), 2018 TS348XD, has bolted an extra Bracket in the area of the chassis that has buckled on my machine. It looks to be approximately 1"x9"x10ga steel stock that is powder coated to match?

The new bracket is called a "Chassis Plate Reinforcement" #593206902. On our Husqvarna Tractors, including the GT6000 Craftsman with the same chassis. Husqvarna has had 3 part numbers in two years for each "improve" to the GT/TS chassis. My new chassis (also by number, I was informed by email when I ordered that it had been superceeded again but not updated in the compter) is the exact same as the 2018 TS chassis, of course without the "fix" bracket.

That"s a lot of changes in such a short amount of time for something that was supposed to be strong enough for the "ground engaging work" that was advertised by Husqvarna for these tractors. The named quick fix bracket "Chassis Plate Reinforcement" sounds like an acknowledgment that the Chassis needed to be reinforced in that area as a type of admission from Husqvarna, but my 5 year warranty is garbage.

My point with a bit of sarcasm, is to point out the apparent design after production fix attempts, by Husqvarna, admitting in a way, that they DO know of their garden tractor frame problem! Are they trying to just re-direct or shift blame on the customer in order to keep this obvious flaw quiet? This does not inspire loyalty.

Their newly introduced Garden Tractor line (identical to the GT48DXLS except the "improves"), 2018 TS348XD, has bolted an extra Bracket in the area of the chassis that has buckled on my machine. It looks to be approximately 1"x9"x10ga steel stock that is powder coated to match?

The new bracket is called a "Chassis Plate Reinforcement" #593206902. On our Husqvarna Tractors, including the GT6000 Craftsman with the same chassis. Husqvarna has had 3 part numbers in two years for each "improve" to the GT/TS chassis. My new chassis (also by number, I was informed by email when I ordered that it had been superceeded again but not updated in the compter) is the exact same as the 2018 TS chassis, of course without the "fix" bracket.

That"s a lot of changes in such a short amount of time for something that was supposed to be strong enough for the "ground engaging work" that was advertised by Husqvarna for these tractors. The named quick fix bracket "Chassis Plate Reinforcement" sounds like an acknowledgment that the Chassis needed to be reinforced in that area as a type of admission from Husqvarna, but my 5 year warranty is garbage.

My point with a bit of sarcasm, is to point out the apparent design after production fix attempts, by Husqvarna, admitting in a way, that they DO know of their garden tractor frame problem! Are they trying to just re-direct or shift blame on the customer in order to keep this obvious flaw quiet? This does not inspire loyalty.

Attachments

Here is what I found out we are up against when the question of legal comes up,

Husqvarna Lawyers know it would be next to impossible/insane for people such as myself, to spend the $5000 retainer to hire a lawyer and set aside approx $40,000 to $50,000 or more and wait upwards of 2 to 4 years to see it through in court for a $148.00 replacement part. That is the reality, not that I want to go to court.

However, if there is a lawyer out there in forum land that wants to take Husqvarna's Warranty on, perhaps with others too? I’m listening, but I am little people, and have no money for the games or privilege of the rich. So without any more options and my time has to be valuable too, I have moved on, except....

Because it appears Husqvarna in their own words violated our States Consumer Protection Laws (more on that with the response I post) I am looking at how to properly file a complaint with Florida Authorities. It doesn't mean they will do anything, and if they do, it can take months or more, but if it's right, I will do it because it is right.

Husqvarna Lawyers know it would be next to impossible/insane for people such as myself, to spend the $5000 retainer to hire a lawyer and set aside approx $40,000 to $50,000 or more and wait upwards of 2 to 4 years to see it through in court for a $148.00 replacement part. That is the reality, not that I want to go to court.

However, if there is a lawyer out there in forum land that wants to take Husqvarna's Warranty on, perhaps with others too? I’m listening, but I am little people, and have no money for the games or privilege of the rich. So without any more options and my time has to be valuable too, I have moved on, except....

Because it appears Husqvarna in their own words violated our States Consumer Protection Laws (more on that with the response I post) I am looking at how to properly file a complaint with Florida Authorities. It doesn't mean they will do anything, and if they do, it can take months or more, but if it's right, I will do it because it is right.

That thin a frame is barely enough for a simple lawn mower, and way too thin for anything called a GT! Laughable....even with their reinforcement plate!

This is what the Fabricators said too! They were amazed with choice field language about it!

Yet if someone armed with this knowledge looks at how the product is represented its downright fraud! My Wife said she looked at the new TS line and couldn't find referrence to it being a GT for "ground engaging work" like my GT did, as if they are trying to still say it is without saying it. If this is true it's slick, I will be trying to confirm this!

The new build is engineered by actual established farm/agricultural fabrication specialists. They worked with me to keep it in a price that would still make sense, and did the job they said they would, on time, and it looks fantastic. I can't thank them enough, they earned my small business period. They are approx 80 miles away from but worth it for the ethical way they do business.

They took the time to study the frame, what I was asking of it specifically to include adding Johnny Bucket, and if the rest of the tractor would be within proper equipment specs, (thinking of the Kawasaki motor, K66, axles, wheels, weights,etc, and dimensions!

I will post the pictures of my first mistake (thinking channel for reinforcement). Then the experts advice and what I've done.

They took the time to study the frame, what I was asking of it specifically to include adding Johnny Bucket, and if the rest of the tractor would be within proper equipment specs, (thinking of the Kawasaki motor, K66, axles, wheels, weights,etc, and dimensions!

I will post the pictures of my first mistake (thinking channel for reinforcement). Then the experts advice and what I've done.

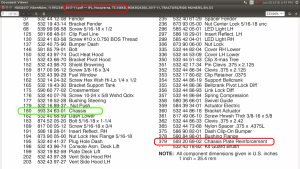

The shop recommended 1/4 steel bar, 3" wide and I went with 5' long, they said it was way overkill but they understood, overkill is what I wanted within reason. If someone put on this plate (weld) from behind the front axle support to the front of the steering support plate they would probably be fine.

My part in prep was to get the new chassis ready for welding by clearing the paint from the areas on the frame where they will weld. Drilling the holes in the 1/4" bar to line up with the frame holes on each side. The idea was to have the steel ready to weld when I got there. It was... ish.

When they put the frame on there machines to clamp the pieces down and check for square they made a note as to where it was buckled or bowed out of square. The area was on the front right side exactly where my old frame buckled. Husqvarna would call it a coincidence or blame it on UPS I'm sure, and its hardly the smoking gun, but... what are the odds and in light of all the other evidence?

They squared the frame for Husqvarna and made the welds adding 25lbs of steel (with a tinsel strength of 70k-80k lbs) to the chassis for a total chassis weight of 51lbs, width on the sides of over a 1/3" of steel to transform it into the foundation of a proper Light Duty Garden Tractor! Something Husqvarna couldn't or wouldn't do.

By the way, any GT owners out there that know what their JDX500, JDX300, Cub Cadet X3, Simplicity, etc frames weight, I have a suspicion I may be at the bottom end of that now with this upgrade, But at least glad to be on the GT train with an extra investment of $370. for the welding and steel, $100.00 for the powder coat, an extra $170.00 for welding the altered front axle brackets, for a grand total of $4,000.00 just on the tractor.

The GT48DXLS is the limited production model with the 24hp Kawasaki FR730V, fabricated mowing deck (the deck blows so much air volume you don't need an extra accessory with the grass catcher!) electric switch differential lock K66 Tuff Torq, Top of the Husqvarna line that I got on sale for approx $3,200.00 and it still needed an extra $800.00 to be what was advertised. I have much more invested in equipment.

I used some very high tech equipment to get my part done for the fabricators such as;

1 Harbor Freight 10'x10' canopy to give some shade from the then July Florida sun, 90f to 92f plus up to 100% humidity, but cooler there than my garage!

1 Harbor Freight 10" 12sp bench drill press and USA steel made drill bits I ordered that were worth the investment, at 300rpm and plenty of chainsaw bar oil, the bits never failed.

This project is being done on my back porch and I have pieces everywhere.

The axle brackets had to be reduced in width by a 1/4" on each side and rewelded to fit inside the frame. Also I put together my own Manual that is laminated and organized by Husqvarna Tractor, Tuff Torq K66 Transaxle, Kawasaki Motor, and accessories used, with all diagrams for each, part numbers, service, and troubleshooting guides.

My part in prep was to get the new chassis ready for welding by clearing the paint from the areas on the frame where they will weld. Drilling the holes in the 1/4" bar to line up with the frame holes on each side. The idea was to have the steel ready to weld when I got there. It was... ish.

When they put the frame on there machines to clamp the pieces down and check for square they made a note as to where it was buckled or bowed out of square. The area was on the front right side exactly where my old frame buckled. Husqvarna would call it a coincidence or blame it on UPS I'm sure, and its hardly the smoking gun, but... what are the odds and in light of all the other evidence?

They squared the frame for Husqvarna and made the welds adding 25lbs of steel (with a tinsel strength of 70k-80k lbs) to the chassis for a total chassis weight of 51lbs, width on the sides of over a 1/3" of steel to transform it into the foundation of a proper Light Duty Garden Tractor! Something Husqvarna couldn't or wouldn't do.

By the way, any GT owners out there that know what their JDX500, JDX300, Cub Cadet X3, Simplicity, etc frames weight, I have a suspicion I may be at the bottom end of that now with this upgrade, But at least glad to be on the GT train with an extra investment of $370. for the welding and steel, $100.00 for the powder coat, an extra $170.00 for welding the altered front axle brackets, for a grand total of $4,000.00 just on the tractor.

The GT48DXLS is the limited production model with the 24hp Kawasaki FR730V, fabricated mowing deck (the deck blows so much air volume you don't need an extra accessory with the grass catcher!) electric switch differential lock K66 Tuff Torq, Top of the Husqvarna line that I got on sale for approx $3,200.00 and it still needed an extra $800.00 to be what was advertised. I have much more invested in equipment.

I used some very high tech equipment to get my part done for the fabricators such as;

1 Harbor Freight 10'x10' canopy to give some shade from the then July Florida sun, 90f to 92f plus up to 100% humidity, but cooler there than my garage!

1 Harbor Freight 10" 12sp bench drill press and USA steel made drill bits I ordered that were worth the investment, at 300rpm and plenty of chainsaw bar oil, the bits never failed.

This project is being done on my back porch and I have pieces everywhere.

The axle brackets had to be reduced in width by a 1/4" on each side and rewelded to fit inside the frame. Also I put together my own Manual that is laminated and organized by Husqvarna Tractor, Tuff Torq K66 Transaxle, Kawasaki Motor, and accessories used, with all diagrams for each, part numbers, service, and troubleshooting guides.

Attachments

-

IMG_0734.JPG152.5 KB · Views: 44

IMG_0734.JPG152.5 KB · Views: 44 -

IMG_0740.JPG173.2 KB · Views: 42

IMG_0740.JPG173.2 KB · Views: 42 -

IMG_0746.JPG334.3 KB · Views: 39

IMG_0746.JPG334.3 KB · Views: 39 -

IMG_0747.JPG262 KB · Views: 37

IMG_0747.JPG262 KB · Views: 37 -

IMG_0753.JPG206.7 KB · Views: 37

IMG_0753.JPG206.7 KB · Views: 37 -

IMG_0760.JPG346.5 KB · Views: 38

IMG_0760.JPG346.5 KB · Views: 38 -

IMG_0761.JPG323.1 KB · Views: 41

IMG_0761.JPG323.1 KB · Views: 41 -

IMG_0767.JPG322.8 KB · Views: 43

IMG_0767.JPG322.8 KB · Views: 43 -

IMG_0770.JPG323 KB · Views: 46

IMG_0770.JPG323 KB · Views: 46 -

IMG_0774.JPG173.2 KB · Views: 47

IMG_0774.JPG173.2 KB · Views: 47

Here are more pics from above; This stage is when I was paint stamping the square holes for the fabricators, they had a punch and charged $1 per punch.