yeah, being in the country there are slim pickings. I got thru town each day dropping kids off to work. I find little gems at times.Scrounging at its best Bret. I sit on the porch a lot especially in the morning. It’s funny at the trucks and trailers go by on trash pickup day. If I sit out there long enough I’ll see some on their way back home with a few good scores. Living in the country it’s hard to find usable stuff tossed out. Years ago I use to hit a few subdivisions in the morning now that’s some good pickings.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY VAWT Project

- Thread starter BMaverick

- Start date

Got a few more free parts.

The interface of the motor pinion gear to be driven can't be weight loaded. The VAWT will need a bearing to take the load.

So, I've been kicking around a few ideas.

I this image, the data CD is the weight load to the motor below it. For scale and size, this works just fine. However, my system will be 20X this size and weight load is critical.

The fun vids of this are here.

bestexperimentideas.com

bestexperimentideas.com

The interface of the motor pinion gear to be driven can't be weight loaded. The VAWT will need a bearing to take the load.

So, I've been kicking around a few ideas.

I this image, the data CD is the weight load to the motor below it. For scale and size, this works just fine. However, my system will be 20X this size and weight load is critical.

The fun vids of this are here.

Electric Power Free Energy Generator With DC Motor 100% New Experiment Science Project at Home

Please Follow Me On:

bestexperimentideas.com

bestexperimentideas.com

Years ago when CB was the big thing and the big stacked directional beams were the thing, rotors that would not handle the load were quickly found. Mounting the rotor on a pipe on top of a tower was not an option as the first weight and 30-40 mph wind would tear it apart. We started to mont the rotors inside the tower and let the tower top tube take side force off the rotors. Then we came up with load bearing bearings mounted above the rotor inside the tower to take the down force or weight off the rotor. That was a lot of fun working up on a 40-60' towers, putting all that together with antennas that were on 20' cross poles. No way would I even consider that today but did it many times as no one else around would do it.

Your prototype is old school for sure but shows exactly what your tyring to accomplish. 3 lids on the CD would be enough and reduce the weight load tremendously. Used a similar set up and would count the number of flashes on the light to get wind speed and syncro motors for wind direction.

Your prototype is old school for sure but shows exactly what your tyring to accomplish. 3 lids on the CD would be enough and reduce the weight load tremendously. Used a similar set up and would count the number of flashes on the light to get wind speed and syncro motors for wind direction.

The motors are mounted, the motor-shields are in place, have a few bearings, a few circular plates, and a mess of ideas.

This recent article from 2017 provided a few more insights.

www.naturalnews.com

www.naturalnews.com

If I do things right, I can change out the rotating blade system on a whim to something else. Its possible to find the best setup for each season actually. Summer winds are slow and need a lighter blade frame. Winters are hard and brutal with winds and would need things really robust. A Spring/Fall turbine would handle those equinox seasons.

The article focuses on the Darriues Wind Turbine (the big hoop), something a bit more complicated over the Lenz Turbine. Taking their findings in a suburban environment and the height under 30FT, the article and links of their research can help anyone kick-start right away with a working project in no time.

This recent article from 2017 provided a few more insights.

Vertical-axis wind turbines potential sources of cheaper electricity in urban and suburban areas, researchers discover – NaturalNews.com

The average onshore wind turbine is a good source of energy, but the same can’t be said of their smaller cousins. To some, the smaller, cylindrical wind turbines are too inefficient to be of any real use. To others, that need not be the case. Lam Nguyen and Meredith Metzger, both mechanical...

If I do things right, I can change out the rotating blade system on a whim to something else. Its possible to find the best setup for each season actually. Summer winds are slow and need a lighter blade frame. Winters are hard and brutal with winds and would need things really robust. A Spring/Fall turbine would handle those equinox seasons.

The article focuses on the Darriues Wind Turbine (the big hoop), something a bit more complicated over the Lenz Turbine. Taking their findings in a suburban environment and the height under 30FT, the article and links of their research can help anyone kick-start right away with a working project in no time.

Last edited:

This concept reminds me of those rotating roof vents.

This one is called the Hurricane.

Here is the Hurricane in action. I bet more power could be had if the silly pigeon got off. It's not an amusement ride for birds.

www.metatube.com

www.metatube.com

This one is called the Hurricane.

Here is the Hurricane in action. I bet more power could be had if the silly pigeon got off. It's not an amusement ride for birds.

#VIRAL: Pigeon Spins on Rotating Roof Vent

#VIRAL: Pigeon Spins on Rotating Roof Vent

One of my motors is a 24VDC 5Amp. There is a way to take 24VDC and up the power to 220VAC. A little math is involved to calculate the up-scaling and amps too.

Why does this relate to the VAWT? Look at how little turns of the crank is needed to generate power.

Intead of the hand crank, the VAWT will be spinning the motor shaft.

So, poking around on the YT this vid popped up.

(turn off annoying sound music and just read the close caption instead.)

The guy have more vids in the comments.

Why does this relate to the VAWT? Look at how little turns of the crank is needed to generate power.

Intead of the hand crank, the VAWT will be spinning the motor shaft.

So, poking around on the YT this vid popped up.

The guy have more vids in the comments.

I'm not sure those would have been a good idea in your application. You don't want to have a problem downstream from them and have them keep resetting and energizing the circuit while unmonitored. Sounds like a good way to start a fire or destroy equipment.I looking into self resetting relays, but those were very pricey.

For the life of me, I had not a clue how those curved DIY blades people made that looked too complicated. The secret is out now!

55 gallon plastic drum vertical axis wind turbine (vawt):

Take a 55-gallon plastic drum and sketch out the blade profile. Then using a simple saw-zaw with lots of fine teeth, cut it out.

Locally, there is a CraigsList person who sells these for a mere $8 each. I have 2 right now for garden watering. hmmm. I wasn't planning on making one so tall. The nice thing about the design, it's so compact and only needs 2 blades.

Why is this design better? Ever watch those figure skaters spin and pick up high velocity as they pull everything in. This keeps things from being pulled apart at higher wind speeds. The shape also acts as a wind break to prevent the gyration from exceeding the upper limits of the design.

The science behind all this is fun. I'm not all that keen on the nit-picky calculations as the math typically can go over the average person's head. haha. Solar is nearly plug and play as the controllers and battery banks can be figured out with average math to a little algebra. Wind is on a calculus level with a twist of trigonometry. (pun intended too. ).

).

So, if I style the outline on a 55-gallon plastic barrel, like that in various images for the motor ranges I have, I'll be in the same in-field of the ballpark vs. being in the bleachers out-of-bounds.

I have about 2-months left of good weather to push this project. The first frost will hit thereafter with the winds already at a constant good clip out here in the mid-west.

55 gallon plastic drum vertical axis wind turbine (vawt):

Take a 55-gallon plastic drum and sketch out the blade profile. Then using a simple saw-zaw with lots of fine teeth, cut it out.

Locally, there is a CraigsList person who sells these for a mere $8 each. I have 2 right now for garden watering. hmmm. I wasn't planning on making one so tall. The nice thing about the design, it's so compact and only needs 2 blades.

Why is this design better? Ever watch those figure skaters spin and pick up high velocity as they pull everything in. This keeps things from being pulled apart at higher wind speeds. The shape also acts as a wind break to prevent the gyration from exceeding the upper limits of the design.

The science behind all this is fun. I'm not all that keen on the nit-picky calculations as the math typically can go over the average person's head. haha. Solar is nearly plug and play as the controllers and battery banks can be figured out with average math to a little algebra. Wind is on a calculus level with a twist of trigonometry. (pun intended too.

So, if I style the outline on a 55-gallon plastic barrel, like that in various images for the motor ranges I have, I'll be in the same in-field of the ballpark vs. being in the bleachers out-of-bounds.

I have about 2-months left of good weather to push this project. The first frost will hit thereafter with the winds already at a constant good clip out here in the mid-west.

Last edited:

LOL, It's clever as a simple plug-n-play. Wish it was this simple. Play the short YT vid and see how the voltages jumps from 9 to 13.x randomly. It will charge a battery as it has a built in Voltage Regulator (VR). It just takes so much wind to get there for a V8 engine fan+clutch assembly to make this work.

Build a Wind Generator for Home with a Car Alternator

Looking to live off-grid or just lower your electricity bill? Turn a car alternator into alternative energy by building this cheap and easy wind generator for home.

www.motherearthnews.com

Looking at the video you'd have to have at least a 25 mph wind to produce any power.It just takes so much wind to get there for a V8 engine fan+clutch assembly to make this work.

Ugh, just when you want to make progress on a hobby, something else suddenly happens. The front steps up to the house gave way. The wood literally rotted out at the base from the inside. Not insect damage, mainly all due to the dampness. We ripped it all off the porch/deck and in the process of rebuilding it all new. $$$.  I was not looking for a home improvement job this year either.

I was not looking for a home improvement job this year either.

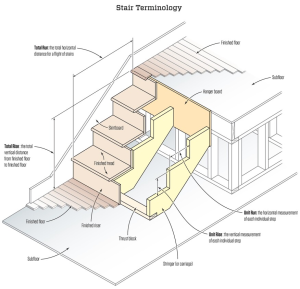

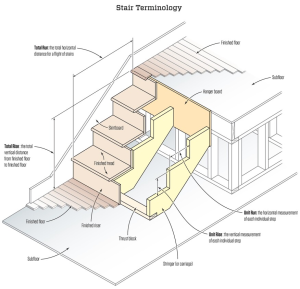

During the tear-down, it was a bit revealing how cheap and the short cuts used to place the stringer boards in place. Just 2X 3-inch deck screw holding them in place vs. metal joist brackets. Freaking scary really. If moving appliances up/down those stairs, they could of just gave way. I'm very surprised the home inspector didn't notice this.

So, the VAWT is on hold for another time.

During the tear-down, it was a bit revealing how cheap and the short cuts used to place the stringer boards in place. Just 2X 3-inch deck screw holding them in place vs. metal joist brackets. Freaking scary really. If moving appliances up/down those stairs, they could of just gave way. I'm very surprised the home inspector didn't notice this.

So, the VAWT is on hold for another time.

I’ve never been impressed with these so called home inspectors. My son and DIL just bought their first house back around Christmas. I did not look at it before they bought it or I would have said run! My youngest daughter and SIL bought their house several years ago against my recommendation s, they have regretted it ever since. Both houses were inspected and approved but with a few suggested repairs that were minor to what the more serious problems were.

Building inspectors are political appointments a lot of times. I did a lot of inspecting for insurance purpose so was all after the house/building was bought. I saw pole building sliding doors hung with roofing nail to hold the rollers. Post that were to short and a 8" piece toe nailed on top and hid with nailers, etc. I could go on for hours.

My comment was about the “home” inspectors that check houses out before they are bought. All the years of building I had good relationships with most all of the “ building “ inspectors. Once they get to know you and see your doing things properly they are easy to work with.Building inspectors are political appointments a lot of times. I did a lot of inspecting for insurance purpose so was all after the house/building was bought. I saw pole building sliding doors hung with roofing nail to hold the rollers. Post that were to short and a 8" piece toe nailed on top and hid with nailers, etc. I could go on for hours.

Only "home" inspectors in this area is for termites, required by the finance company or for insurance purpose. The big cities have building inspectors and make periodic inspections during construction by never dealt with any of that during my construction days.My comment was about the “home” inspectors that check houses out before they are bought. All the years of building I had good relationships with most all of the “ building “ inspectors. Once they get to know you and see your doing things properly they are easy to work with.

OK, back on topic here ...

This is NOT the way to do wind power generation. LOL

www.activistpost.com

www.activistpost.com

Environmental issues include wind turbines emitting extremely toxic sulfur hexafluoride (SF6). Adding insult to injury, “It has been known for decades how dangerous the substance is”.

So, tell your green-buddies that these technologies are still huge pollution generators. Waubra disease is a serious health threat to all air breathing people and animals. It can kill. SF6 prevents the body from exhaling enough C02 that in time, your blood levels become toxic and die a little later.

Up to 25% of the population in the USA are affected by this. Mainly those who life and work in areas with wind turbine fields.

This is NOT the way to do wind power generation. LOL

Intergovernmental Panel Warns “strongest greenhouse gas in the world being emitted from wind turbines”, 26,087x More Harmful than CO2 - Activist Post

Adding insult to injury, “It has been known for decades how dangerous the substance is”.

Environmental issues include wind turbines emitting extremely toxic sulfur hexafluoride (SF6). Adding insult to injury, “It has been known for decades how dangerous the substance is”.

So, tell your green-buddies that these technologies are still huge pollution generators. Waubra disease is a serious health threat to all air breathing people and animals. It can kill. SF6 prevents the body from exhaling enough C02 that in time, your blood levels become toxic and die a little later.

Up to 25% of the population in the USA are affected by this. Mainly those who life and work in areas with wind turbine fields.

Interesting information. The nearest wind farms are over 20 miles from our home but more and more of them are being erected all the time. I had never heard of SF6 but it sounds like nasty stuff as far as the environment is concerned. I makes one wonder if these towers are so healthy why is it necessary to have the land owners sign a form that restricts them from discussing any negative effects they may suffer from them??????SF6 prevents the body from exhaling enough C02 that in time, your blood levels become toxic and die a little later.