You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

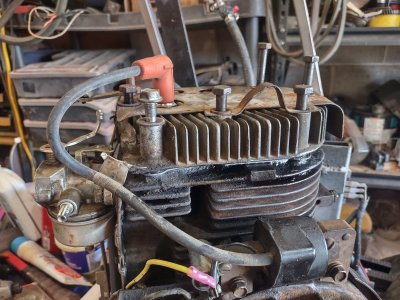

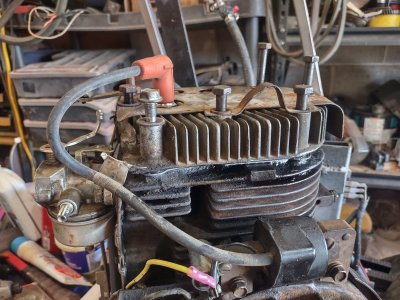

Hh100 Rebuild

- Thread starter esbbent

- Start date

No standard bore, the replacement piston fit good. The ring gap was good also, I always check before installing the rings on the piston.Did you have to go with an overbore, Ted?

DAC

Good deal, Ted. The HH120 I wanted to rebuild back in 2015 was so out of round a BDC that the top ring land was scuffing. Needed to go .020. No pistons available then that was cheaper than just doing a repower.No standard bore, the replacement piston fit good. The ring gap was good also, I always check before installing the rings on the piston.

DAC

Quite a bit of progress today. The new crankshaft seals arrived Friday so both seals were installed and the side cover bolted on. This is a early Techumseh with points and magneto. There's a points rod similar to a Kohler to open and close the points. then the points are installed and gapped to .020. the points are the same as Kohler points you just have to take them off the holder.

then the points are installed and gapped to .020. the points are the same as Kohler points you just have to take them off the holder.

the red wire from the points connects to the capacitor by the magneto coil. The yellow wire goes to the key switch, when key is off it grounds out and kills the engine.

the red wire from the points connects to the capacitor by the magneto coil. The yellow wire goes to the key switch, when key is off it grounds out and kills the engine. the head was installed and torqued down and the metal shields were installed. I wanted to start it on my engine test stand but the mount for the starter generator is bolted to the frame of the tractor not the engine. The engine is sitting in the tractor. I plan on bolting it down tomorrow and firing it up.

the head was installed and torqued down and the metal shields were installed. I wanted to start it on my engine test stand but the mount for the starter generator is bolted to the frame of the tractor not the engine. The engine is sitting in the tractor. I plan on bolting it down tomorrow and firing it up.

then the points are installed and gapped to .020. the points are the same as Kohler points you just have to take them off the holder.

then the points are installed and gapped to .020. the points are the same as Kohler points you just have to take them off the holder.

the red wire from the points connects to the capacitor by the magneto coil. The yellow wire goes to the key switch, when key is off it grounds out and kills the engine.

the red wire from the points connects to the capacitor by the magneto coil. The yellow wire goes to the key switch, when key is off it grounds out and kills the engine. the head was installed and torqued down and the metal shields were installed. I wanted to start it on my engine test stand but the mount for the starter generator is bolted to the frame of the tractor not the engine. The engine is sitting in the tractor. I plan on bolting it down tomorrow and firing it up.

the head was installed and torqued down and the metal shields were installed. I wanted to start it on my engine test stand but the mount for the starter generator is bolted to the frame of the tractor not the engine. The engine is sitting in the tractor. I plan on bolting it down tomorrow and firing it up.I still sweat it out a bit when I use the MF1450 after I rebuilt the K321, Bill! Not the correct block for the narrow oil pan

DAC

Just need it to start . I tried to start it last night but no spark and I ran out of time and patience. I will have to double check the magneto gap and points gap when I get home.You made some fast progress, Ted! That first start after a rebuild is a good feeling!

DAC

I should have just took the time to figure out how to mount my extra starter generator to the engine stand vs installing in the tractor. It is a little easier to check and work on on the stand.

Hope you get or got it figured out Ted! That would be nice having an engine stand with the starter generator!Just need it to start . I tried to start it last night but no spark and I ran out of time and patience. I will have to double check the magneto gap and points gap when I get home.

I should have just took the time to figure out how to mount my extra starter generator to the engine stand vs installing in the tractor. It is a little easier to check and work on on the stand.

DAC

I reset the magneto gap last night, it's a little closer now. Still no spark. I ran out of time to look at it anymore last night. I am planning on taking the magneto off and try cleaning the flywheel and see if it makes any difference. If still no spark it will be changed over to a external 12v coil set up like a k series Kohler. I already have the coil and condenser.

Not much if any progress yesterday and today. I tried the 12 volt coil using the points on the engine still no spark. Checked point gap 3 times with no change. I put the spark tester on my MF12 to make sure the tester was working. I tested the magneto with multi meter and it looks like the magneto is no good. I was debating on changing out the flywheel to the SSI style with the trigger pins and change it to the GM hei module ignition. I instead decided to put in the Kohler k301 sitting on my shelf. May have been a bad decision. The long fuel tank will not fit, the oil drain is in the way of moving the engine back far enough, and the low mount starter needs changed to a high mount starter. The starter is not a issue I have a spare starter and have a high mount flywheel cover.

More to come when I have an update

More to come when I have an update

Going to name this tractor Murphy. I decided to go ahead and put the Kohler engine in the tractor. It is not a easy swap, new mounting holes had to be drilled in the frame. The oil drain is at the back of the engine and with the wide oil pan being off set on the bolt pattern the pan can't be swapped around. I had to get a close tolerance brass pipe street elbow and had barely enough clearance for it to fit. The throttle cable and choke cable are not long enough. I have a roll of the outer housing and wire to make new cables. The next concern is how to mount the belt bracket on the Kohler engine.

You have been having a battle with this, Ted! When I did the re-power on my MF12G changing the oil became a big mess. Metric drain plugs too. Ran across a 12V marine duty engine oil pump cheap. I just suck the oil out now rather than try to drain it. Always pulls out 1 quart, which is what the engine requires.Going to name this tractor Murphy. I decided to go ahead and put the Kohler engine in the tractor. It is not a easy swap, new mounting holes had to be drilled in the frame. The oil drain is at the back of the engine and with the wide oil pan being off set on the bolt pattern the pan can't be swapped around. I had to get a close tolerance brass pipe street elbow and had barely enough clearance for it to fit. The throttle cable and choke cable are not long enough. I have a roll of the outer housing and wire to make new cables. The next concern is how to mount the belt bracket on the Kohler engine.

DAC

It is testing my patience. The worst part is it's parked in front of my garage. I need to get it done or moved before the s@#_& starts so I can get the MF12 with the snowblower parked inside. I also need to move my haban sickle mower out of the garage.You have been having a battle with this, Ted! When I did the re-power on my MF12G changing the oil became a big mess. Metric drain plugs too. Ran across a 12V marine duty engine oil pump cheap. I just suck the oil out now rather than try to drain it. Always pulls out 1 quart, which is what the engine requires.

DAC

Hopefully the s-word will hold off for a long time, Ted!It is testing my patience. The worst part is it's parked in front of my garage. I need to get it done or moved before the s@#_& starts so I can get the MF12 with the snowblower parked inside. I also need to move my haban sickle mower out of the garage.

DAC

The piston off of ebay from the little red barn (if i remember correct). The gasket seal kit from Isavetractors.com and the connecting rod was off of ebay. Rod was NOS.Hi Ted,

Where did you find the new parts that you ordered for the engine?

Some progress is made. It is finally running, I spent some time checking the wire from the points and noticed there was no continuity to ground when turning the engine over. It took a few minutes before the lightbulb went off, I didn't have the points gapped at the correct time. Adjusted the points, reinstalled the coil magneto and it has spark and runs. Tomorrow if the rain stops I plan on removing the Kohler and putting the Techumseh back in.

Good to find the problem and that the engine is running, those cast iron Tec sure do run niceSome progress is made. It is finally running, I spent some time checking the wire from the points and noticed there was no continuity to ground when turning the engine over. It took a few minutes before the lightbulb went off, I didn't have the points gapped at the correct time. Adjusted the points, reinstalled the coil magneto and it has spark and runs. Tomorrow if the rain stops I plan on removing the Kohler and putting the Techumseh back in.