To save that pulley you can grind a v deep down into both sides of that spoke, then weld with nickel rod. First get a wood fire going and toss the pulley into the fire. While good and hot weld her up, then toss back into that fire, throw a few more sticks of wood into the fire then let it sit till fire dies out. This can help prevent cold cracking.. if any weld protrudes into the taper just grind out with a die grinder.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kemp K6CH Wood Chipper

- Thread starter Sawdust

- Start date

That sounds like a good plan Daniel. After a little research before I started I’ve only welded cast iron two times and it worked out good. I’ll probably tinker with it this winter it won’t be long the wood stove in the shop will be burning. Thanks Daniel as always for the encouragement and advice.To save that pulley you can grind a v deep down into both sides of that spoke, then weld with nickel rod. First get a wood fire going and toss the pulley into the fire. While good and hot weld her up, then toss back into that fire, throw a few more sticks of wood into the fire then let it sit till fire dies out. This can help prevent cold cracking.. if any weld protrudes into the taper just grind out with a die grinder.

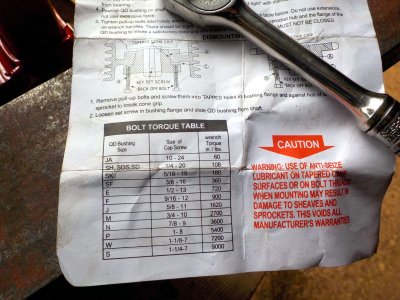

Sorry to hear that the pulley cracked on you. The small wood chipper that I built and updated last year uses a split hub and pulley set up similar to yours for mounting the pulleys to the shafts. While the pulley may be a different size to yours the split sheaves for mine came with specific instructions and they show torque specifications in "inch pounds" for various size bolts and specifically mention not to use anti-size or other lubricants. I also searched and found a Browning split hub instruction sheet that I have attached which also mentions that using lubricants on the barrel, hub or bolts may result in breakage. Just thought I would mention this in case you were not aware of it.You can bet I’ll be nervous about this new one. I only brought the two bolts in a quarter turn at a time very slowly going back and forth from one bolt to another.

Attachments

That damage could have happened when you used the puller to get it off the shaft.

Thanks Stew those torque specs are handy to have. No on the lubricants, I actually dried and cleaned the surfaces before installing the new pulley.Sorry to hear that the pulley cracked on you. The small wood chipper that I built and updated last year uses a split hub and pulley set up similar to yours for mounting the pulleys to the shafts. While the pulley may be a different size to yours the split sheaves for mine came with specific instructions and they show torque specifications in "inch pounds" for various size bolts and specifically mention not to use anti-size or other lubricants. I also searched and found a Browning split hub instruction sheet that I have attached which also mentions that using lubricants on the barrel, hub or bolts may result in breakage. Just thought I would mention this in case you were not aware of it.

I thought about that but as I was tightening the bolts I heard it pop. My first thought was oh crap! that’s not good. It could have still been the reason and it just broke clear through later.That damage could have happened when you used the puller to get it off the shaft.

My pulley came last Saturday and it’s a perfect match.

Even though I had already balanced the drum without a pulley I went ahead and balanced it again with the new pulley. It stayed the same with the same spot on the drum stopping at several different areas.

I’ve had this burn pile growing for awhile due to burn bans. I had three cedar trees in there so I pulled them out, cut the limbs off, cut up the trunk for firewood, and chipped the rest. This thing runs like a new one. I’m not exaggerating but before all four wheels would dance around while running and the noise was horrible. Now it just sits there on its own doing it’s job. It has a door and a flap for adjusting the chips so I have to explore that some, this first time using the chips were a little too small.

I definitely have to change the towing design, it’s way too unstable as is. My thoughts are jacking it up and finding the middle balance point first. While making it slightly heavier on the tongue figure out a way to add two wheels at that point without interfering with the drum. This would make it more stable, tow better, able to back it up, and move around by hand. I would also while using either leave it hitched or add an adjustable kickstand. Thanks everyone for your input and thoughts.

Even though I had already balanced the drum without a pulley I went ahead and balanced it again with the new pulley. It stayed the same with the same spot on the drum stopping at several different areas.

I’ve had this burn pile growing for awhile due to burn bans. I had three cedar trees in there so I pulled them out, cut the limbs off, cut up the trunk for firewood, and chipped the rest. This thing runs like a new one. I’m not exaggerating but before all four wheels would dance around while running and the noise was horrible. Now it just sits there on its own doing it’s job. It has a door and a flap for adjusting the chips so I have to explore that some, this first time using the chips were a little too small.

I definitely have to change the towing design, it’s way too unstable as is. My thoughts are jacking it up and finding the middle balance point first. While making it slightly heavier on the tongue figure out a way to add two wheels at that point without interfering with the drum. This would make it more stable, tow better, able to back it up, and move around by hand. I would also while using either leave it hitched or add an adjustable kickstand. Thanks everyone for your input and thoughts.

Sounds like you did a good job especially in the balancing!! I'll suggest making the axle longer for stability and build a removeable axle with swivel casters for easier manuevering and you can easily remove it for chipping with a tongue jack for support w/o the axle in place. If the grate is removeable and you want coarser material find some old 1" crusher screen that's worn pretty thin and bend it to fit a new frame and weld it to the frame. I say worn screen because new or near new screen is hard to bend because it's high carbon steel .

I should have read your earlier posts as I found one where you said you can make an adjustment to make coarser material.

I should have read your earlier posts as I found one where you said you can make an adjustment to make coarser material.

Last edited:

It actually has what they call a “ 3 Position Discharge Door”. The fully closed position which I had it in keeps the material in the basket longer creating a finer material. As you open it, it allows the material to exit the basket faster creating a more coarse material.Sounds like you did a good job especially in the balancing!! I'll suggest making the axle longer for stability and build a removeable axle with swivel casters for easier manuevering and you can easily remove it for chipping with a tongue jack for support w/o the axle in place. If the grate is removeable and you want coarser material find some old 1" crusher screen that's worn pretty thin and bend it to fit a new frame and weld it to the frame. I say worn screen because new or near new screen is hard to bend because it's high carbon steel .

I should have read your earlier posts as I found one where you said you can make an adjustment to make coarser material.

That machine is doing a great Job, nice work Jim! Sounds like it really runs smooth now. Do those front wheels steer with the hitch? Reason I ask is we have an old Hotsy steam cleaner at work. All four wheels are fixed straight and that thing is heavy. Just about impossible for one man to turn it! Probably why no one uses it and it just sits with spiders living in it. Sure looks like a wider track would help, but I like ol' Stonebreakers idea with a wider single axle.

DAC

DAC

Thanks for sharing the pictures of the finished product after it goes through the chipper. I assume that the size of the chips you would like to see it produce would be similar to the ones I get with my chipper?

Attachments

Yeah Doug the front wheels steer with the hitch it’s like backing up an accordion.That machine is doing a great Job, nice work Jim! Sounds like it really runs smooth now. Do those front wheels steer with the hitch? Reason I ask is we have an old Hotsy steam cleaner at work. All four wheels are fixed straight and that thing is heavy. Just about impossible for one man to turn it! Probably why no one uses it and it just sits with spiders living in it. Sure looks like a wider track would help, but I like ol' Stonebreakers idea with a wider single axle.

DAC

That would be good. That’s the only thing I don’t like about this is the bottom discharge. It wasn’t bad picking up the tarp with the chips on it but would be much better shooting them in a trailer.Thanks for sharing the pictures of the finished product after it goes through the chipper. I assume that the size of the chips you would like to see it produce would be similar to the ones I get with my chipper?

Wonder if you could make a small hopper / tray section out of plywood or chip board that could sit on the ground under the outlet with a slight slope and have 3 sides higher to contain the chips and then have the open side that could feed the chips into a short elevator section that could move the product up to the trailer level? Could use a hoe or rake to push or pull the chips out of the hopper on to a small apron chain set up with slats on the elevator (similar to a manure spreader) that could be hand cranked every so often to move the product upwards on an incline to the trailer. Could also power the apron chain set up with a 12 volt winch motor that could run off the tractor battery. Just a suggestion to think on depending on the amount of chipping you will be doing each year.That would be good. That’s the only thing I don’t like about this is the bottom discharge. It wasn’t bad picking up the tarp with the chips on it but would be much better shooting them in a trailer.

If you could find an old pull behind combine they used drag elevators for cyl return and grain to the bin.

I have two chippers, one is bottom discharge the other is side discharge.That would be good. That’s the only thing I don’t like about this is the bottom discharge. It wasn’t bad picking up the tarp with the chips on it but would be much better shooting them in a trailer.

The bottom discharge seem to just drop the chips on the ground under the chipper to be picked up with a fork. Not a big deal but you do have to stop chipping to deal with the chips occasionally. That chipper doesn't seem to move a lot of air so the smaller stuff you feed into the shredder feed tends to bridge easily and requires a lot of pushing.

The side discharge moves lots of air and can blow the chips 20 or 30 feet to the side if there is an unobstructed path. It also tends to suck in the stuff in the shredder feed and so feed more effectively and smoothly. This means it will spread the chips over a large area. Attempting to direct the air flow hasn't worked out for me so far and mostly just caused plugging.

All that said I have found the most effective way to move and deal with the chips to be a pitchfork.

Don

I have my MTD chipper/shredder mounted on the back of a riding mower I use as a fan for leaf collection, however I can unhook the leaf trailer, take the discharge hose off and mount the curved discharge deflector, remove the suction hose and mount the shredder chute. I have a peice of OSB I set on my contractors wheelbarrow with a notch cut in it the discharge chute will fit into shred/chip garden waste or wood. If there's a lot of wood I can also leave the discharge hose attached and blow it all in the trailer. It's a pretty versatile setup.

Sounds like something we would love to have pictures of. Maybe even a Video.I have my MTD chipper/shredder mounted on the back of a riding mower I use as a fan for leaf collection, however I can unhook the leaf trailer, take the discharge hose off and mount the curved discharge deflector, remove the suction hose and mount the shredder chute. I have a peice of OSB I set on my contractors wheelbarrow with a notch cut in it the discharge chute will fit into shred/chip garden waste or wood. If there's a lot of wood I can also leave the discharge hose attached and blow it all in the trailer. It's a pretty versatile setup.

Don