Not sure that isn’t a blessing. This thing is no Marvel-Sweibler, that’s for sure.I don't have one either. Mine doesn't have the right carb.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Way Engine model EH Type 2

- Thread starter MH81

- Start date

I second that emotion! That's one neat old engine Alan!Awesomesauce!

Yes.Does that engine have roller bearings on the crankshaft?

Hey Doug, any idea if the clutch on these are wet or dry? I just took mine all apart and it appears it had some oil in there. Not full of fluid or anything, but the plates all had a sticky "glue" that was the consistency of pine pitch, smelled like old oil, and acted like it was baked on.I'm pretty sure they do, Chris.

This is metal and fiber alternating discs. Probably 8-9 of each.Not real sure on that one. The earlier New Way clutch was metal to metal plates and you had to give it a little oil to keep it from grabbing/sticking. It didn't really run in oil though.

I think it should have some lube unless someone says no.

Guessing 30w-ish would be ok?

With the fiber, I'd maybe think mineral oil instead of petroleum. Is the housing sealed enough to hold oil? The early ones had a spring loaded check ball that you shoved down with the oil can spout and gave it a couple squirts every now and then. Too much and it slipped. Not enough and it stuck.

Yes, the outside moves. The check ball really only drops oil to the brass where it spins on the shaft, not intended to dump inside, but I'm sure it will get in there.If it doesn't stick, it might be better to leave it dry. Maybe a little dry graphite to let them slide? Does the outside of that pulley move to engage it? That was how the early ones worked.

Mineral oil. That's what the old stuff was, I'm almost sure of it.. the brake parts cleaner reacted differently than I expected.

I wanted to put together a short post on the inside of the clutch on this.

I knew the clutch was spring loaded inside, so I decided I would do foot long pieces of 5/16 all thread.

there are 6 bolts that hold this unit together, so I took out three of the bolt and replaced them with the all thread.

Be sure to use lock nuts on the one end or you may accidentally unscrew the wrong end and get hurt or damage the clutch.

And I slowly unscrewed the nuts on the all thread a few turns at a time

When I finally got the all threads unscrew to where there is no spring pressure on them, I went ahead and disassembled the clutch. There is a fairly sizable spring in there that rides on a bearing, and multiple (approximately 8 each) steel plates between fiber discs

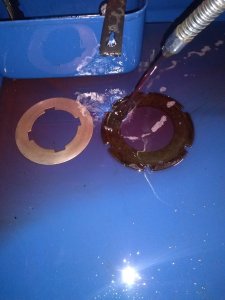

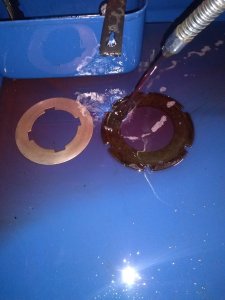

after the clutch came apart, the plates were stuck to the fiber discs. Almost like they were glued together.

The plates came loose and were washed.

And here it is reassembled.

And working

I knew the clutch was spring loaded inside, so I decided I would do foot long pieces of 5/16 all thread.

there are 6 bolts that hold this unit together, so I took out three of the bolt and replaced them with the all thread.

Be sure to use lock nuts on the one end or you may accidentally unscrew the wrong end and get hurt or damage the clutch.

And I slowly unscrewed the nuts on the all thread a few turns at a time

When I finally got the all threads unscrew to where there is no spring pressure on them, I went ahead and disassembled the clutch. There is a fairly sizable spring in there that rides on a bearing, and multiple (approximately 8 each) steel plates between fiber discs

after the clutch came apart, the plates were stuck to the fiber discs. Almost like they were glued together.

The plates came loose and were washed.

And here it is reassembled.

And working

Last edited:

Yeah, I wouldn't want to take it apart without the all thread. Be picking up stuff for an hour.Healthly looking spring!