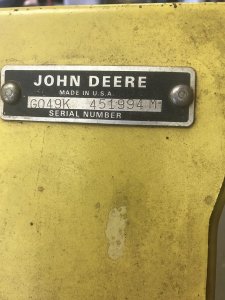

Gunna try and fix some rust on the snowthrower that goes on the JD 140H3. This thrower came of a JD 317. Put those flapper things on it. Never saw any difference, even at the first before they were worn out. Nothing left of them.

Noel

Noel