Yeah that’s the problem of needing to heat just the hub and staying away from the axle, not much room in there.<<< I can’t get a torch in there without burning the tire to heat the hub and axle>>>

You don't want to heat the axle. Just the hub, and only in one spot. An old welder/fabricator told me that several years ago. The trick is to expand the hub so it will release from the axle. To much heat, or for to long and you expand both and defeat the purpose.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picked Up A White Rear Tine Tiller

- Thread starter Sawdust

- Start date

Another thing that I learned long ago was that often the problem is the key/keyway where a pulley/wheel/gear/whatever hangs up on the most so if you do heat the wheel start near the keyway. And if it isn't a woodruff style get in there with a small flat punch and try to drive the key a little bit farther one way or the other and see if you can get that to budge.

Also could be a burr from a setscrew holding it up from moving

Also could be a burr from a setscrew holding it up from moving

DT I used your method of dealing with the key first on my MTD990 drive shaft several years ago with good results. This tiller only has a pin on each wheel hub. I haven’t had much time to work on this. I was thinking about plugging up the pin hole and keeping it full of penetrating oil hoping it travels across the axle.

Attachments

That might work Doug. Lol This thing unlike a tractor when it comes to lifting it with a floor jack it’s very unstable which prevents me from muscling it any. Right now I don’t need it as before because I used my JCPenney’s tiller bc and got the gardens prepped for winter. I may just wait later after the holidays to work on it again.Just start tilling with it with the pin out Jim! I guarantee the wheel will fall off right when you don't want it too---LOL!

DAC

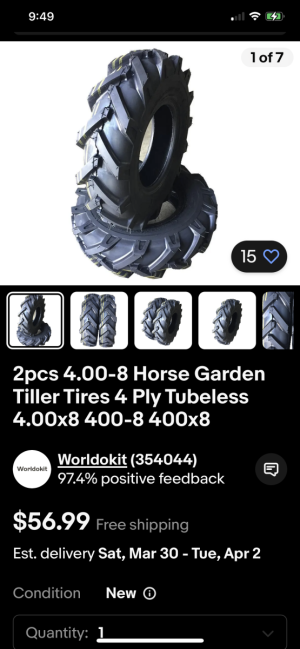

Well it’s been about four months but for the past month I’ve been soaking it, heating, tapping and pulling at it with a three jaw puller with no results. I haven’t been able to heat the hub like I wanted to because of the tire getting too hot and wanting to burn. Today I took the tire off which wasn’t too bad but now I’m thinking this tire is in worse shape than I thought. The side walls are split bad but the other one holds air good. Even though my plan was to tube these I’m thinking now maybe replacing the tires too.

Once I got the tire off I could direct the heat better but still no budging this thing at all. About noon I got real smart and thought about using my hammer drill to see if it would break up some of the rust by hammering on the hub while rotating the wheel. All I had was a lot of carbide bits and two chisel bits. I sacrificed my worst carbide bit and grounded it flat. I put my drill on hammer only and started working it back and forth on the frozen hub. It was crazy at the cloud of fine rusty dust coming out of the pin hole, I thought this is great! Doing this for about five minutes my three jaw puller fell off indicating the hub was moving off. I put the puller back on and torqued it a little bit but now my center bolt on the puller bottomed out. I keep a bunch of old various sockets as spacers for things like this so I put one in on the end of the shaft and torqued away and it’s off now. I had a little time before the race came on so I straightened up some bad spots on the wheel where the pullers jaws were. Now that I know what I’m doing the other one I’m hoping will be easier.

Once I got the tire off I could direct the heat better but still no budging this thing at all. About noon I got real smart and thought about using my hammer drill to see if it would break up some of the rust by hammering on the hub while rotating the wheel. All I had was a lot of carbide bits and two chisel bits. I sacrificed my worst carbide bit and grounded it flat. I put my drill on hammer only and started working it back and forth on the frozen hub. It was crazy at the cloud of fine rusty dust coming out of the pin hole, I thought this is great! Doing this for about five minutes my three jaw puller fell off indicating the hub was moving off. I put the puller back on and torqued it a little bit but now my center bolt on the puller bottomed out. I keep a bunch of old various sockets as spacers for things like this so I put one in on the end of the shaft and torqued away and it’s off now. I had a little time before the race came on so I straightened up some bad spots on the wheel where the pullers jaws were. Now that I know what I’m doing the other one I’m hoping will be easier.

Attachments

I had one fight me one time, wasn't a wheel. Was a pulley for the starter/generator and the PTO clutch basket on a cub 127. I bought one of those puller tools made by "parts by Jeff" whose pretty well known on the cub cadet sites. Wouldn't budge. I heated it with an acetylene torch, after I left it under pressure if the puller tool for a good couple of months, soaking it at least once a week during that time, usually twice a week .. kept putting a socket on it to see if I could get anything on it, I finally got it to move, git it flush with the end of the crank and no more. I wound up cutting it off. I cut the pulley from the OD of the groove to the center, in line with the keyway and finally got it off. Fortunately I had another one of those pullies. I ended up having to build 1 engine out of 2 because the keyway on the other cub spec k301 I had was all beat to snot and no longer usable.

If I still had a buddy that worked in a tool room of a factory I could have had him take it to work and cut a new keyway across from the bad one but those days are gone

This is on the engine I'm putting together for my cub 129.

If I still had a buddy that worked in a tool room of a factory I could have had him take it to work and cut a new keyway across from the bad one but those days are gone

This is on the engine I'm putting together for my cub 129.

I cleaned up the beast wheel which wasn’t as bad as it looked. Sprayed some black gloss coat Rustoleum on the inside and smoke gray on the outside. I cleaned up the shaft with some emery cloth and ran a half round file on the inside of the hub. The thing slides on and off now like it should. I have to get some more anti seize. I cooked it for awhile to get it warm before painting as our friend Kenny use to say. Him and I were firm believers painting in cold weather get the metal and spray bombs warm before using.

Needless to say the other wheel is as stubborn too. I worked about a half hour yesterday heating soaking and hammering with the hammer drill. I’ll let it sit awhile soaking.

This made me feel better about late morning.

Needless to say the other wheel is as stubborn too. I worked about a half hour yesterday heating soaking and hammering with the hammer drill. I’ll let it sit awhile soaking.

This made me feel better about late morning.

No but I love a good maple donutMmmmm..... are you a policeman?

Your not alone in this thinking. I have a shelf on the front of the stove in the shop to warm up paint cans and parts before painting and after they go on there to dry. Works great.Him and I were firm believers painting in cold weather get the metal and spray bombs warm before using.

I got the other beast wheel off using the same procedure. This tiller has the same dark, medium, and light gray color combination as my White 1885. Since I’m rebuilding the tractor I have these colors. I didn’t like the Smoke gray which is the medium color that I used on the wheels. They were suppose to be the light color so repainted both wheels. I ordered two replacement tires which was just shipped today. I won’t be using the inter tubes now so I’ll just save them for another time.

Attachments

Even though these tillers do not have a rear PTO like those BSC types, it's possible to other attachments if you do a minor modification.

The Yanmar and Kubota 2-wheel tractors can uses these.

If I find an old tiller like your White or a Cub with a broken tiller system, I would love to convert it over the a 2-wheel tractor ability.

The Yanmar and Kubota 2-wheel tractors can uses these.

If I find an old tiller like your White or a Cub with a broken tiller system, I would love to convert it over the a 2-wheel tractor ability.

Well all dressed up and nowhere to go this morning. The engine started up just fine after two pulls. I drove it out to the garden and tilled about 5’ and the tines stopped turning. No forward or reverse in the tines. I tried turning them by hand which would indicate a sheared pin or chain off but no turning them. Forward, reverse, and neutral in the drive wheels works fine just no power to the tines. I’ll try and find a manual for this again no luck before on a White. Several other brands are similar so hopefully I can get this going. If not I’ll get my old reliable bone shaking JCPenney out later on the week. I have to admit the tires look good

I know some of the Craftsman rear tillers used a sheer bolt of sort similar to what snowblowers used but bigger. Matter of fact still have some but the tiller is long gone . Almost thinking they're 5/16 . Be kinda strange for both to break at the same time though.Well all dressed up and nowhere to go this morning. The engine started up just fine after two pulls. I drove it out to the garden and tilled about 5’ and the tines stopped turning. No forward or reverse in the tines. I tried turning them by hand which would indicate a sheared pin or chain off but no turning them. Forward, reverse, and neutral in the drive wheels works fine just no power to the tines. I’ll try and find a manual for this again no luck before on a White. Several other brands are similar so hopefully I can get this going. If not I’ll get my old reliable bone shaking JCPenney out later on the week. I have to admit the tires look good

View attachment 80803

Oh no, that will turn you into a Jelly-Fish Man !Well all dressed up and nowhere to go this morning. The engine started up just fine after two pulls. I drove it out to the garden and tilled about 5’ and the tines stopped turning. No forward or reverse in the tines. I tried turning them by hand which would indicate a sheared pin or chain off but no turning them. Forward, reverse, and neutral in the drive wheels works fine just no power to the tines. I’ll try and find a manual for this again no luck before on a White. Several other brands are similar so hopefully I can get this going. If not I’ll get my old reliable bone shaking JCPenney out later on the week. I have to admit the tires look good

View attachment 80803

After watching a few YouTube videos I found three other tillers exactly like mine but hardly any info on a White brand. Two problems can cause this, one the more simple fix is a broken chain the other is a shift fork. If the forks on the shift fork spread apart it doesn’t shift the gears into all the gear ranges. That fork kit is between $110.- $150.  The chain of coarse would be just buying a length of chain and a master link. Either way for right now I’m going to shelf this project. I don’t feel like having this thing torn apart and not fixing it right away. Like I mentioned I’ll be getting the bone shaker out later in the week.

The chain of coarse would be just buying a length of chain and a master link. Either way for right now I’m going to shelf this project. I don’t feel like having this thing torn apart and not fixing it right away. Like I mentioned I’ll be getting the bone shaker out later in the week.