You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strongland tractor

- Thread starter Ron

- Start date

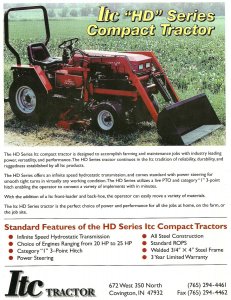

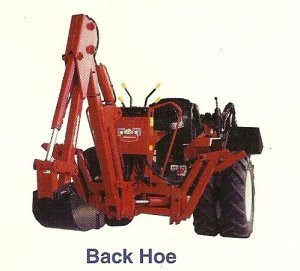

The 2474 may also have a 2nd hydraulic pump front of engine under the rad area driven buy a belt from the electronic clutch on the side of the engine. The pump operates a rear hydraulic motor for tillers, backhoes etc.. Very heavy duty & rugged. Both pumps are made by Oilgear & identical.My 1631 weighs 870 lbs. The 2474 is going to be a little heavier, maybe 970 - 1000. Plus the loader.

The hoods, fenders, belt guards & dashes were contracted out to local fab shops in the area. The steel is very thick & well made. Really overbuilt. Nothing was stamped out. I saw pallets of them at the plant waiting to be used.The hood probably wasn't tooled and made in a press brake. With low volumes it's hard to recoup tooling costs.

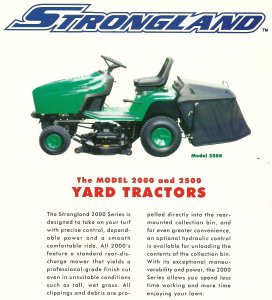

Rare Strongland small electric trencher. Inside the Armstrong tractor (Strongland) factory. Strongland Yukon tractor. Dealer ad for Strongland Tractors.

Attachments

Last edited:

Seems like I saw an English lawn tractor that had a similar rear bagger setup. That was a good solution for attaching a bagger...... much better, in my opinion, than the tube attaching to a side chute.Never produced Strongland yard tractor

A friend of mine worked at the plant assembling the tractors. Was at the factory several times & eventually obtained the factory files with most of the build prints. Obtained several units from the assembly line when they closed I completed.I take it you worked at the Strongland factory and had a hand in building these machines?

YesAll of those are interesting in their own ways.

Besides the prototype, did the others make it to where they were offered for sale to the public?

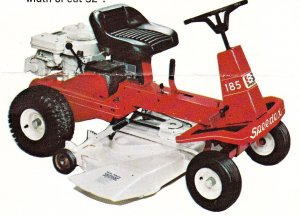

This ones a 1/2 size scale of the Strongland 1872 I built from scratch just to see if I could do it. Slightly smaller than the 1950's S series Speedex tractors.