I wasn't saying to unhook the trailer, just jack up a ways without lifting the back wheels of the truck off the ground. I can gain 4-6" of front height that way and loose that sharp ramp angle!Yes but I don't like doing that. Turns the whole trailer loose - no parking brakes on it. I just watch where I park as much as I can and try to make sure the ground at the end of the drop down is high enough to clear the hinge point. Back wheels of the truck higher than the trailer wheels helps too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoping to Build This Soon.

- Thread starter KennyP

- Start date

Finding a tube that will slip fit over the axle after it is cut in the middle is a good way to extend an axle. The more lap of the new tube over the old axle the better. The forces on the center of the axle are small. I extended an axle to move a shed weighing several hundred lbs with a 2x4 and gear clamps.If I were widening that axle, I'd try to find a solid piece of the same size, weld it in, then use 2 1/2 x 1/2 plate on front and back, a foot past each butt weld, welding it in along the length only....no vertical welds.

Don

That may work with a shorter single axle trailer. I lift the hitch on mine about 8" to unhook it and the back hardly moves. 16' tandem landscape trailer.I wasn't saying to unhook the trailer, just jack up a ways without lifting the back wheels of the truck off the ground. I can gain 4-6" of front height that way and loose that sharp ramp angle!

Mine is the same trailer!That may work with a shorter single axle trailer. I lift the hitch on mine about 8" to unhook it and the back hardly moves. 16' tandem landscape trailer.

Have you tried to find 1-3/4" ID square tube with 1/4' WALL anywhere! Doesn't exist!Finding a tube that will slip fit over the axle after it is cut in the middle is a good way to extend an axle. The more lap of the new tube over the old axle the better. The forces on the center of the axle are small. I extended an axle to move a shed weighing several hundred lbs with a 2x4 and gear clamps.

Don

Have you tried to find 1-3/4" ID square tube with 1/4' WALL anywhere! Doesn't exist!

Just 1/4" plate would be better. You would be running a bead right along the axle. 4 plates & you've made a much stronger splice than using square tube.

If in doubt ... use 3/8" plate.

.

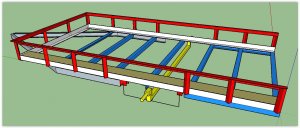

Updated the drawing some. Added top rails and a support under the rear section along with one board.

Not doing anything at the wheel/fender area as yet!

What drawing program are you using Kenny ?

.

Might try Onshape: cad.onshape.com

You have to be online ti use it, but all the computer heavy lifting is done on their servers. The free account lets you do about everything, only caveat is that your drawings are publicly viewable.

But it is powerful enough for most needs, I do most of my daily work in it.

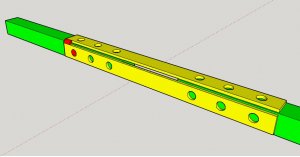

Here is a link to the drawing I did for that handle I forgot about: Onshape

You have to be online ti use it, but all the computer heavy lifting is done on their servers. The free account lets you do about everything, only caveat is that your drawings are publicly viewable.

But it is powerful enough for most needs, I do most of my daily work in it.

Here is a link to the drawing I did for that handle I forgot about: Onshape

You could use 2"x 1/4" angle. Trim the edges of the legs to fit to each other and cut oval holes for plug welds . After plug welding weld the edges together.

Mike

Mike

That was my thinking also it would give good lateral welds along with the plug welds.You could use 2"x 1/4" angle. Trim the edges of the legs to fit to each other and cut oval holes for plug welds . After plug welding weld the edges together.

Mike

Where are these parts you are talking about?You could use 2"x 1/4" angle. Trim the edges of the legs to fit to each other and cut oval holes for plug welds . After plug welding weld the edges together.

Mike

I'm sorry, Kenny, what parts are you referring to? On re-reading my post I see I should have explained to trim the edges 'til the two pieces fit snugly on the axle. A small piece of flat bar welded to the corner of each piece of angle will provide a flat spot for the C-clamps to squeeze the angles on the axle. I'll suggest making the angles have at least 12" of overlap on each end of the axle.

Mike

Mike

I have tried a couple different CAD programs including Sketch up. Took longer to figure them out than it did to do the drawing with a scale ruler and pencil. I usually don't need a fancy cad drawing anyway. Quick sketch with some measurements on it and good to go.

Thanks, Glenn, that's what I was trying to describe.

Mike

Mike

Now I'm on the same page! I won't be doing anything to the axle.Thanks, Glenn, that's what I was trying to describe.

Mike