I'm thinking about 15 years or more ago, I posted a bunch of photos of parts that I had gotten for an Agricat crawler.

Here is the main body for the crawler.

This part is still in storage out at my sons place and it will most likely be a couple of weeks before we can did it out.

Some of the parts for the two rear drive clutches.

Parts for the suspension and front idler wheel supports.

The two front idler wheels.

The tracks.

The top left six track links on the front track are all frozen together so those will have to be freed up.

the rest of the track links all move freely.

There were a lot more photos of other parts but this gives you an idea of what I'm starting out with.

The first thing that I'm going to work on is the engine and that is sitting on a shelf up in the loft.

So, using my new remote operated hoist, I raise my lift cart up to the loft.

It was a lot easier doing this with the remote switch. I was able to stay down on the lower level and keep the cart from hanging up against the side wall as I raised it up.

Then I go up onto the loft and swing the cart inside.

Using the cart, I'm able to easily get the engine off the shelf.

The engine is then lowered down onto my diecart.

The engine is a Wisconsin TJD twin cylinder.

The hoist cable is reeled back up and the gate is closed.

Here is the main body for the crawler.

This part is still in storage out at my sons place and it will most likely be a couple of weeks before we can did it out.

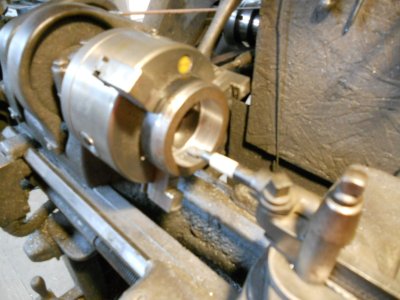

Some of the parts for the two rear drive clutches.

Parts for the suspension and front idler wheel supports.

The two front idler wheels.

The tracks.

The top left six track links on the front track are all frozen together so those will have to be freed up.

the rest of the track links all move freely.

There were a lot more photos of other parts but this gives you an idea of what I'm starting out with.

The first thing that I'm going to work on is the engine and that is sitting on a shelf up in the loft.

So, using my new remote operated hoist, I raise my lift cart up to the loft.

It was a lot easier doing this with the remote switch. I was able to stay down on the lower level and keep the cart from hanging up against the side wall as I raised it up.

Then I go up onto the loft and swing the cart inside.

Using the cart, I'm able to easily get the engine off the shelf.

The engine is then lowered down onto my diecart.

The engine is a Wisconsin TJD twin cylinder.

The hoist cable is reeled back up and the gate is closed.

Last edited: