I sure hope so. I always fear something failing after I work on it.Gunna be great.

Noel

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

John Deere 60 repairs

- Thread starter cjet69

- Start date

I have pretty much all of the parts back on the tractor except for the hood, grille, flywheel cover, exhaust pipe, and steering shaft. I need to set the timing and fill with water and then its time to go for startup and check it over for any issues like water or oil leaks. Hopefully this will happen tomorrow. If all goes well, I can finish up the wiring for the alternator and button everything up.

Attachments

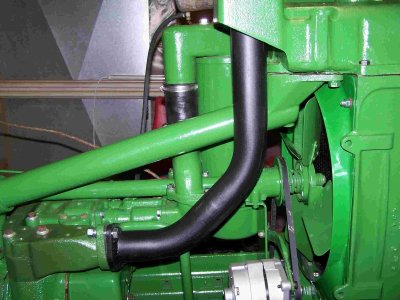

Miracles do happen. The JD 60 runs again after 25 years. After filling the carb with fuel and the radiator with water it popped on the first revolution of the starter and after choking for a couple turns it came to life. It seems to rum good. The oil pressure came up right away and the charging system is working. When filling the radiator, we noticed the water pump was leaking out the weep hole. After running for a while, it is still leaking so my cousin is going to order a new one along with a new exhaust pipe. I guess after 25 years some things are going to get lost. Need to finish tidying up the wiring, change out the water pump, and get the steering shaft, hood, and grille installed and then maybe it can go home.

I was surprised that there weren't more leaks of oil, water, and gas. Hope it stays that way.Hey cjet I like it really like it. No feeling quite so good as when an engine starts and runs so nice. Maybe you should tell your cousin that it needs to stay at your place for the summer to get it broke in so he doesn't have to worry

Last edited:

Always a nervous time no matter how well you know you did the work, as even brand new parts can fail. Wishing you the best!I sure hope so. I always fear something failing after I work on it.

Miracles do happen. The JD 60 runs again after 25 years. After filling the carb with fuel and the radiator with water it popped on the first revolution of the starter and after choking for a couple turns it came to life. It seems to rum good. The oil pressure came up right away and the charging system is working. When filling the radiator, we noticed the water pump was leaking out the weep hole. After running for a while, it is still leaking so my cousin is going to order a new one along with a new exhaust pipe. I guess after 25 years some things are going to get lost. Need to finish tidying up the wiring, change out the water pump, and get the steering shaft, hood, and grille installed and then maybe it can go home.

Attachments

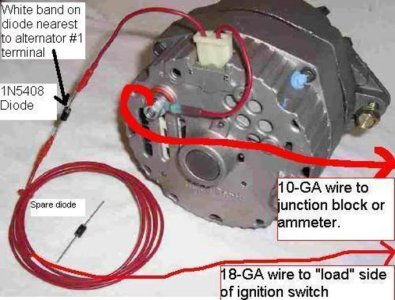

I need to make a change in the wiring for the alternator. As it is right now it feeds back and keeps the coil powered up so the tractor doesn't shut off with the switch. Had to pull one wire off the alternator to kill it. I'll be adding a pressure switch to separate the alt. from the coil power at the switch. I think the same thing can be accomplished with a diode also, but I am more familiar with the pressure switch setup.

Thanks, GB. Good to knowHi cjet a simple diode is really easy to install inline but what ever works is good also a red warning light installed in the dash or a resistor also works

Since I already had the pressure switch in hand I went ahead and installed it. The tractor shuts off with the switch now and in the process, it got a new oil line to replace the old rust pitted one. Next time I run into this I will try putting in a diode.

Attachments

The new exhaust pipe showed up today, but no water pump. The new exhaust pipe doesn't fit very good. It sits at an angle at the bolt flange and doesn't center it the hole in the muffler mount that's part of the radiator top tank. If I cut the pipe at turn it slightly I think it would work, but that is up to the cousin and what he wants to do. Gotta luv aftermarket parts.

Attachments

After looking at it some more, I think the bolt flange wasn't in the proper position when welded. It would take a lot of careful grinding to cut it loose from the pipe. Probably more than a guy would want to do especially after paying for a new one. Also found if the pipe is not center in the muffler mounting flange you can't bolt down the muffler.Yea that's not good it is aggravating when parts don't fit or align, a guy almost hates to cut and weld a brand new pipe

Sounds to me the seller needs to send a good replacement, I was wondering if the flange maybe didn't squared before welding, that would be a lot of grinding to get it off and alignedAfter looking at it some more, I think the bolt flange wasn't in the proper position when welded. It would take a lot of careful grinding to cut it loose from the pipe. Probably more than a guy would want to do especially after paying for a new one. Also found if the pipe is not center in the muffler mounting flange you can't bolt down the muffler.

I agree. My cousin is getting anxious to get the tractor back, even more so after hearing it run. Every time he has to order new parts it's another week that goes bye. I've about run out of time also with hay season upon us. If the weather cooperates, we may start cutting in 2-3 days.Sounds to me the seller needs to send a good replacement, I was wondering if the flange maybe didn't squared before welding, that would be a lot of grinding to get it off and aligned

Well, I pulled the bolts out of the exhaust pipe and just held it in place to check alignment. It looked like I could slot the mounting holes in the flange far enough to make it work. Used a burr bit in a die grinder and moved the holes 1/4" to 3/8" and put the pipe back on. Looks like this will do it. I can now center the pipe up in the muffler mount. I could grind a little more if I had to, but the flange would be getting might thin and need some welding to reinforce it. The water pump showed up this afternoon also. It is made to fit all of the model from early to late 60's, so i has a bypass in it and comes with a plug for models without the bypass. The bypass hole has an O-ring for the seal and the plug is stepped with a knurled bottom end that gets tapped into the water pump casting to hold it in place. The plug on this one was loose when it was all the way in so I put some Loctite on the top end above where the O-ring sits. I'll get some paint on it tomorrow and see if I can get it installed Thursday.

Attachments

-

100_5307-m.jpg113.9 KB · Views: 3

100_5307-m.jpg113.9 KB · Views: 3 -

100_5309-m.jpg146.4 KB · Views: 3

100_5309-m.jpg146.4 KB · Views: 3 -

100_5310-m.jpg162.9 KB · Views: 3

100_5310-m.jpg162.9 KB · Views: 3 -

100_5311-m.jpg181.9 KB · Views: 3

100_5311-m.jpg181.9 KB · Views: 3 -

100_5313-m.jpg121.3 KB · Views: 3

100_5313-m.jpg121.3 KB · Views: 3 -

100_5314-m.jpg132.9 KB · Views: 3

100_5314-m.jpg132.9 KB · Views: 3 -

100_5317-m.jpg155.6 KB · Views: 3

100_5317-m.jpg155.6 KB · Views: 3 -

100_5319-m.jpg136.3 KB · Views: 3

100_5319-m.jpg136.3 KB · Views: 3 -

100_5318-m.jpg220.3 KB · Views: 3

100_5318-m.jpg220.3 KB · Views: 3