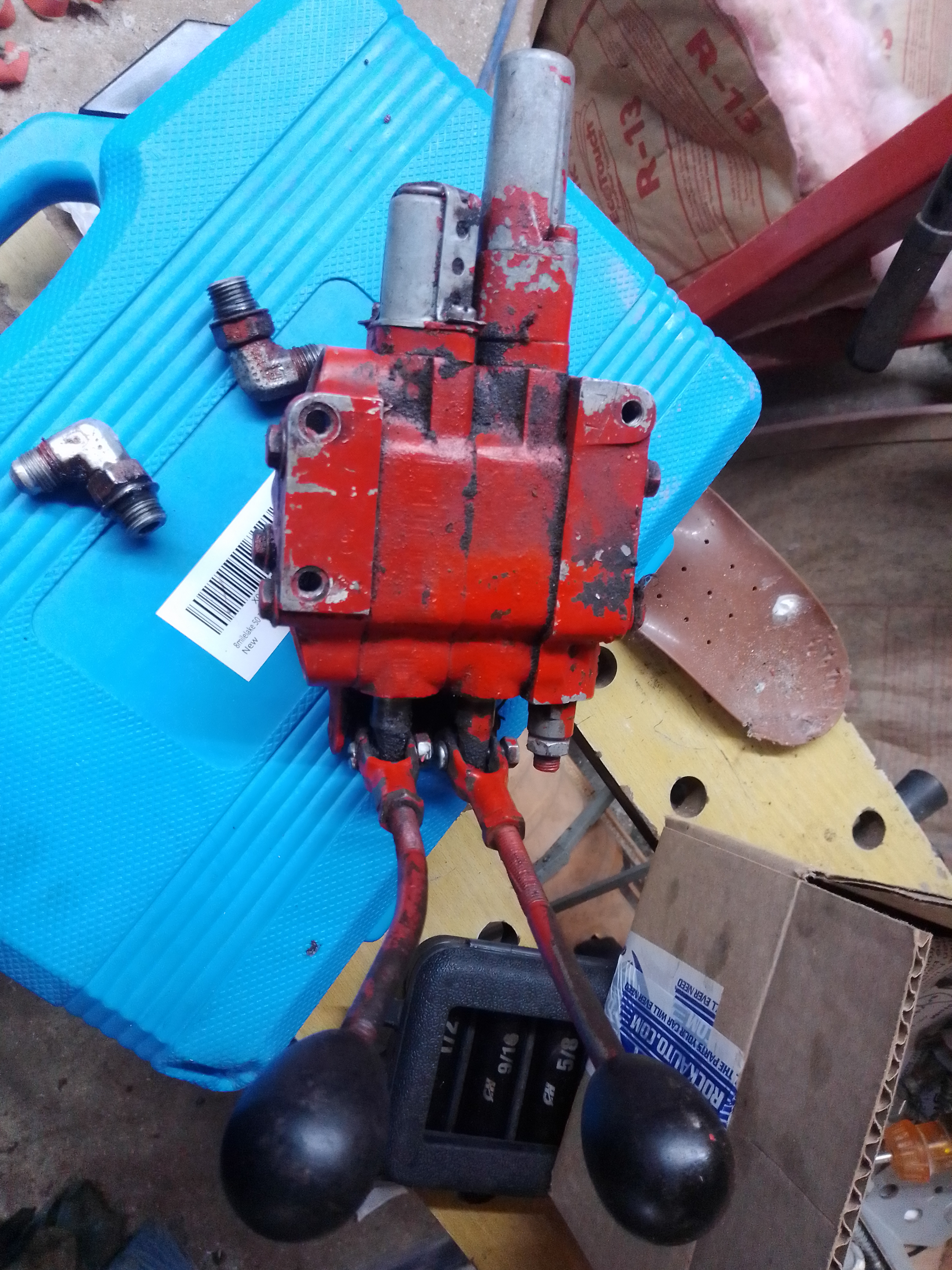

Not Daniel, but I can confirm that it is a relief valve, and that the Massey 1655 manual shows this valve having a relief in it.Hey Daniel just curious if this valve that was off of a Massey originally? It looks like it but it also looks like it has a relief valve on the right, most of those didn’t come with relief valves. Hopefully that’s what it is?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Massey 1655 Loader Build

- Thread starter jason silliker

- Start date

Yes, that is a relief valve and came on the 1655 chassis I bought to put the loader on. No, most don't have a relief, so this is really good in that you don't have to add one. No idea how high the relief can be set. I think I raised it slightly. I used that loader to move a Massey 1100 bare engine, and I checked stats and naked engine weighs 1,080 pounds. I had to hook behind the bucket to get it to lift it. Moved it out of old shop into a small shed, and it still remains there.Hey Daniel just curious if this valve that was off of a Massey originally? It looks like it but it also looks like it has a relief valve on the right, most of those didn’t come with relief valves. Hopefully that’s what it is?

Sweet. That was a concern with using the factory ones. I never checked the manual yet but I checked both of mine before I posted and neither has one hence the post lol. Hmmm

I think you posted that video on YouTube didn’t you?Yes, that is a relief valve and came on the 1655 chassis I bought to put the loader on. No, most don't have a relief, so this is really good in that you don't have to add one. No idea how high the relief can be set. I think I raised it slightly. I used that loader to move a Massey 1100 bare engine, and I checked stats and naked engine weighs 1,080 pounds. I had to hook behind the bucket to get it to lift it. Moved it out of old shop into a small shed, and it still remains there.

And I forgot to change the relief on the new valve (factory set to 2500 PSI!), and picked up a 1200lb milling machine! Of course, I blew a fitting the next day...... fixed that and set the loader pressure to 1100 PSI. The 3 point is running 650 PSI, right in the factory range.Yes, that is a relief valve and came on the 1655 chassis I bought to put the loader on. No, most don't have a relief, so this is really good in that you don't have to add one. No idea how high the relief can be set. I think I raised it slightly. I used that loader to move a Massey 1100 bare engine, and I checked stats and naked engine weighs 1,080 pounds. I had to hook behind the bucket to get it to lift it. Moved it out of old shop into a small shed, and it still remains there.

No, but wish I did. Dad could have done the video for me, as son Josh had to sit on my rear weights to give me enough traction to get up the slight rise in the concrete getting out of the old shop. Once I got out, I had plenty traction, so he got off.I think you posted that video on YouTube didn’t you?

Yup that’s the one lolNo, but wish I did. Dad could have done the video for me, as son Josh had to sit on my rear weights to give me enough traction to get up the slight rise in the concrete getting out of the old shop. Once I got out, I had plenty traction, so he got off.

Yeah the manuals show them but they say most never had them, it’d weird to have them since the pump has the in line relief valve anyway. Probably a case of different shipments to them from Cessna valves?The MF valves I put on Alice have the relief valve.

Hey Sarge, so the spool with the long cover would indicate a "float" valve? I've pretty much got zero experience building hydraulics. Does look like the 2 spool on the MF1450 may have a float valve on it. That other two spool is one I got out of the garbage at work. I know the single on the MF8E doesn't. I had to mechanically allow the blade to float.Well, it flowed great! But I wanted to switch to a joystick, so I replaced it with a new valve. I think I remember where I put it, it was the two spool, one with float. Want it?

DAC

Last edited:

I'm not much more experienced myself! Daniel and KennyP know far more about this stuff than I do, but yes, the long cap is the float spool. With it installed facing you, like it was on my loader, pulling it all the way back past the detent put it in float. The detent position made the arms constantly lift, so be careful with it, or maybe eliminate the detent.Hey Sarge, so the spool with the long cover would indicate a "float" valve? I've pretty much got zero experience building hydraulics. Does look like the 2 spool on the MF1450 may have a float valve on it. That other two spool is one I got out of the garbage at work. I know the single on the MF8E doesn't. I had to mechanically allow the blade to float.

DAC

View attachment 35686 View attachment 35687 View attachment 35688

Yes Doug the long cover does indicate a float valve like Kenny said pretty much all of those series came with float valve for the deck so it’ll move up and down and if you had three point it was an next valve in line and it doesn’t float and it had a spot for a third valve but it was a non-floating valve but you could order the floating valve is well.Hey Sarge, so the spool with the long cover would indicate a "float" valve? I've pretty much got zero experience building hydraulics. Does look like the 2 spool on the MF1450 may have a float valve on it. That other two spool is one I got out of the garbage at work. I know the single on the MF8E doesn't. I had to mechanically allow the blade to float.

DAC

View attachment 35686 View attachment 35687 View attachment 35688

I think I will do this to the three-point on mine, Kenny. It has the mechanical float for plowing, but I need to defeat that to use the three point to carry the backhoe I'm working on.Yes, that is a 'float' spool. What I did on Alice (since it controls the 3-point lift) was hook the hoses so that 'float' is when I lower the lift and can use the 'float' when plowing.

Thanks, Sarge! If I ever get to pressurize that system, every little bit of info like this is valuable! Building a backhoe? You have a lot more knowledge about his than you are letting on!I'm not much more experienced myself! Daniel and KennyP know far more about this stuff than I do, but yes, the long cap is the float spool. With it installed facing you, like it was on my loader, pulling it all the way back past the detent put it in float. The detent position made the arms constantly lift, so be careful with it, or maybe eliminate the detent.

If this stuff works as it should on my project, Kenny, having a float on the deck lift is what I would want as it may get a mowing deck added in the future. 3 point has the mechanical float like Sarge mentioned.Yes, that is a 'float' spool. What I did on Alice (since it controls the 3-point lift) was hook the hoses so that 'float' is when I lower the lift and can use the 'float' when plowing.

Thanks for the info, I didn't mean to hijack your thread, but I'm full of questions about this subject and I'm told full of it in other ways too---LOL!Yes Doug the long cover does indicate a float valve like Kenny said pretty much all of those series came with float valve for the deck so it’ll move up and down and if you had three point it was an next valve in line and it doesn’t float and it had a spot for a third valve but it was a non-floating valve but you could order the floating valve is well.

Great thread, Jason!

DAC

Last edited:

No problem Doug, the more info the better! Eventually I want to have the 3rd valve on the tractor as well & have 2 sets of ports at the rear, I'll remove the MMM cylinder & use it as an adjustable top link on this one seeing as if I put a loader on I won't need it there anyway.Thanks, Sarge! If I ever get to pressurize that system, every little bis of info like this is valuable! Building a backhoe? You have a lot more knowledge about his than you are letting on!

If this stuff works as it should on my project, Kenny, having a float on the deck lift is what I would want as it may get a mowing deck added in the future. 3 point has the mechanical float like Sarge mentioned.

Thanks for the info, I didn't mean to hijack your thread, but I'm full of questions about this subject and I'm told full of it in other ways too---LOL!

Great thread, Jason!

DAC

Not really, I just have a tendency to jump in headfirst! But I am a machinist and mechanical designer by trade, so the work so far has been nothing new. All the flat pieces have been cut, so I'm heading into my personal wilderness: welding!Thanks, Sarge! If I ever get to pressurize that system, every little bis of info like this is valuable! Building a backhoe? You have a lot more knowledge about his than you are letting on!

DAC

As much as I like my projects, I should have let you build me a loader and shipped it with the valves to save me some time lolNot really, I just have a tendency to jump in headfirst! But I am a machinist and mechanical designer by trade, so the work so far has been nothing new. All the flat pieces have been cut, so I'm heading into my personal wilderness: welding!

I'd have to drive my truck up there to deliver it! Hmmm, never been to Eastern Canada...... LOL!As much as I like my projects, I should have let you build me a loader and shipped it with the valves to save me some time lol

I’m going to start mocking up the pump off the front PTO shaft. I was thinking of a piece of splined coupler and see if I could one end 3/4” to fit the pump or just use a piece of shaft 3/4” keyed on one end and just 1” bore on the other end with set screws (don’t like this option as much) 15 spline is harder to find here ugh.