You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sears ST/16 with a Predator (now Kohler)engine

- Thread starter KennyP

- Start date

Started on the battery tray this morning. Cut 2 pieces of angle iron and got mounting holes drilled for them. Put the plate on top (needs trimmed some yet).

Trimmed the plate and welded things up. Added a small angle to the back.

Slid the engine back after trimming the 'ears' for the old tray mount.

Right rear bolt hole would be impossible.

Next post!

Trimmed the plate and welded things up. Added a small angle to the back.

Slid the engine back after trimming the 'ears' for the old tray mount.

Right rear bolt hole would be impossible.

Next post!

Cut the clutch mechanism off the old battery tray this morning and located it to the 'new' battery tray. Just tack welded it for now. Got some trimming to do plus possible 'remodel' of clutch components.

Here's where the trimming needs to be:

And this is how that clutch pulley is in relation to the crank pulley.

Right now to declutch & stop, you will be tensioning the belt. Gotta think on this a bit.

Here's where the trimming needs to be:

And this is how that clutch pulley is in relation to the crank pulley.

Right now to declutch & stop, you will be tensioning the belt. Gotta think on this a bit.

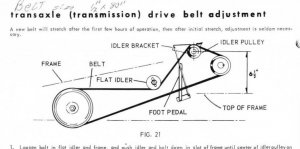

Yes. The top pulley is the clutch. It has a tang on it to keep the belt on. That is what will be putting tension on the belt when you try to stop/shift gears since the crank pulley is so high. Have an idea working. Just got the new lower idler yesterday.Does it look like this?

I found that the little tang on the clutch pulley not only keeps the belt on, in the release position it also provides friction on the belt to resist turning. The first two of the 6 speed Sears tractors I got had belt guards and guides missing. Since I had never seen them complete and properly adjusted I didn't know any better. I made them function ok with tedious fine adjustment and on one I added a return spring to the clutch peddle. Then I got the third one with a worn out belt but all guards and guides in place and couldn't believe how strong and positive engagement was. When I replaced the belt on that one the adjustment was very simple and straight forward.

Don.

Don.

On mine when you push on the clutch/brake pedal it releases tension on the belt and that tang pinches the belt so it stops it from turning the transaxle pulley.

I found that the little tang on the clutch pulley not only keeps the belt on, in the release position it also provides friction on the belt to resist turning.

Don.

Yep, what he said.

I found that the little tang on the clutch pulley not only keeps the belt on, in the release position it also provides friction on the belt to resist turning. The first two of the 6 speed Sears tractors I got had belt guards and guides missing. Since I had never seen them complete and properly adjusted I didn't know any better. I made them function ok with tedious fine adjustment and on one I added a return spring to the clutch peddle. Then I got the third one with a worn out belt but all guards and guides in place and couldn't believe how strong and positive engagement was. When I replaced the belt on that one the adjustment was very simple and straight forward.

Don.

My issue is the engine pulley (crank centerline) is a lot higher and a bigger diameter. I understand what the tang is supposed to do, but in this situation it is in the wrong location. I'm going back out in a bit. Rather foggy out there right now.On mine when you push on the clutch/brake pedal it releases tension on the belt and that tang pinches the belt so it stops it from turning the transaxle pulley.

The belt guard around the pulley on the transmission is just as important as the tang on the clutch pulley in making things function properly.My issue is the engine pulley (crank centerline) is a lot higher and a bigger diameter. I understand what the tang is supposed to do, but in this situation it is in the wrong location. I'm going back out in a bit. Rather foggy out there right now.

Don

I think it's still on there, haven't looked as yet but the belt is staying on that pulley. I'm sure I will need a longer belt than the 5/8" X 81" it's supposed to have. Waiting on an 8" 3-jaw puller to arrive to see about pulling the electric clutch off the crank. That will make it easier to see what length I'll need hopefully.

Here's my idea on the clutch. Using the clutch from a vertical shaft mower, V-pulley is bigger and mounted higher.

In the first pic, notice the bolt in the upper left and the distance. And the second pic.

The two pinned together at the pivot:

Both flipped over:

Wanted the PTO clutch off and remembered my bushing puller. The PTO had grooves in the outer part, found the right size insert and tightened it up. A few 'love taps' on the slide hammer pulled it right off there.

Crank pulley came loose as well. That is a 5" pulley.

Emory cloth cleaned the crankshaft.

In the first pic, notice the bolt in the upper left and the distance. And the second pic.

The two pinned together at the pivot:

Both flipped over:

Wanted the PTO clutch off and remembered my bushing puller. The PTO had grooves in the outer part, found the right size insert and tightened it up. A few 'love taps' on the slide hammer pulled it right off there.

Crank pulley came loose as well. That is a 5" pulley.

Emory cloth cleaned the crankshaft.

Last edited:

Ok I follow you now. When I did an engine swap I actually had to raise the motor to put the crank in the same position as the stock engine,My issue is the engine pulley (crank centerline) is a lot higher and a bigger diameter.

you are facing a different problem. Good luck on engineering the solution. Rick

Workin' on it!Ok I follow you now. When I did an engine swap I actually had to raise the motor to put the crank in the same position as the stock engine,

you are facing a different problem. Good luck on engineering the solution. Rick

Kenny, the Sears pulley will be hitting the mail tomorrow!Here's my idea on the clutch. Using to clutch from a vertical shaft mower, V-pulley is bigger and mounted higher.

View attachment 30380

In the first pic, notice the bolt in the upper left and the distance. And the second pic.

View attachment 30379 View attachment 30378

The two pinned together at the pivot:

View attachment 30377

Both flipped over:

View attachment 30376

Wanted the PTO clutch off and remembered my bushing puller. The PTO had grooves in the outer part, found the right size insert and tightened it up. A few 'love taps' on the slide hammer pulled it right off there.

View attachment 30375 View attachment 30374 View attachment 30373

Crank pulley came loose as well. That is a 5" pulley.

View attachment 30372

Emory cloth cleaned the crankshaft.

View attachment 30371

The K321 has an 1-1/8" shaft!Kenny, the Sears pulley will be hitting the mail tomorrow!

Gonna be a bit before I get back to this. Have a job to do for a friend. Two 10' X 12' floors to build in a pole building, one will get sheet metal walls, a door & windows.

I did start making up a lower part for the hood to hinge off the grille. No pics as yet. It's strap iron, but should function. I'll get pics when I get back on it.

I did start making up a lower part for the hood to hinge off the grille. No pics as yet. It's strap iron, but should function. I'll get pics when I get back on it.