Update, (05JUL2019)

This build was shared between 2 forums. As I update between the two I try to keep them both up to speed. So I'll share the same info. I included the professionals that came up with the chassis design and their credentials are numerous, if interested.

I believe I may have the “Newest Fully Restored” Garden Tractor in the US, possibly in North America.

My story of how I got to this build is told in “Beware of Husqvarna Garden Tractors”. I intentionally told it as it unfolded, not trying to offend anyone, though, understandably, I was very upset. I had been deceived, out right lied too, slandered, accused, and wife too, from the original Dealer, and then Husqvarna.

I found out that many Husqvarna GT owners going back before 2012 have been in the same place, and endured the same or similar Corporate Abuse I had, but with a twist….. many were afraid to be public and endure the ridicule from other owners. This upset me too. I would rather defend the most naive and trusting of people than the most cold and morally bankrupt, even when it’s a Business. So I took this straight on, the good and the bad. I haven't always tackled things that might make me look good (this seemed disingenuous to me) .... I just do my best.

If someone seeks out my original story, I warn you it’s raw. The reason, is how offensive it all became to me over a $150 chassis, and the words “Husqvarna will never warranty their chassis, ever!” “If there is a problem with their tractor it will show up the first day of use” helped contribute also. Yep, from the Dealer, Backed up by Husqvarna, because, according to Husqvarna, those decisions are left to their authorized representatives, so they stand.

This story, “The Build” originally started here,

http://www.floridametalcraft.com/PDF...20Observer.pdf

with seeking out the right kind of expertise to properly assess, guide, confirm, and of course fix my tractor. They know how to keep their word.

My confidence in knowing that Husqvarna miss-represents their Garden Tractor started with engineers and craftsman in the agricultural machinery field, then I had a base of knowledge to study the subject.

Once I understood why the Husqvarna chassis for their GT/ TS is incapable of the stress of “ground engagement work”, and collected the evidence that proves this, the hard part was to communicate the evidence.

An interesting journey and at times running into a possible few Husqvarna Representatives that may have hid behind aliases as this, online,

but were actually this

so they could be this

while they were really trying to say this

and as the evidence would be presented they did this

, Some might say "dog-piling or gas-lighting" too, not willing to discuss in the open the evidence as I have routinely requested. I guess when you don’t have any actual evidence to defend a specific position, a person is left with the choice to,

1) Slander

2) Intimidate

3) Deflect

4) Minimize

5) Call a truce

6) Ignore

My ideal, let’s talk.

In Conclusion;

The project has turned out well. The tractor works well. I really like it, and it's a real pleasure to operate. If you are buying one for mowing, and want a tough mower, it's a bargain and comfortable, Kawasaki is a plus.

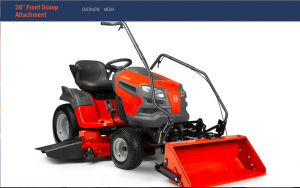

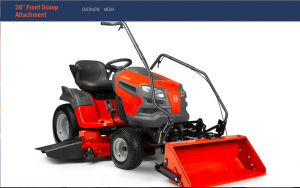

If contemplating a Garden Tractor, let's face it the cheapest

fully capable Garden Tractor in our market I can find does not come with a mower deck for $9K, making this look very appealing.

I would say if looking at it as a $3,700 project, there are some good used projects out there that may be better.

If you just want to do it because you want to prove it can be done, with modifications, why stop there, I haven't seen one plow a farm yet (a real farm 100 acres +), that would be interesting. Also full set of tracks would be great too!

If you find yourself already owning one and concerned of it's limitations or worse, the best advice I can give you is this;

The biggest difference was adding the extra 1/4" hard steel and extending all the way to the back of the rear sleeve plate.

One continuous welded piece on each side from the very front to the very back (the extra 3" beyond the original chassis, the TS chassis is 57" long). The rear sleeve plate on the Husqvarna TS354D (GT), as an example has a lot of stress placed on it, but does not have full support of the chassis because the chassis doesn't go all the way to the back.

It's crazy to think now, that Husqvarna would actually try and make people believe that their top of the line tractor at $3,700. (now),

Even the rest of the world, as an example,

Even the rest of the world, as an example,

Being structurally "capable" of Ground Engaging work.

It's the Chassis (like a house foundation),

The Transmission,

The Motor,

That make a tractor "capable" of ground engagement work, not colorful marketing and empty promises.

The difference in pan chassis between this tractor;

And this one ???

The pan chassis in this tractor,

Is identical in gauge, and dimension except is 1" shorter overall, has extra steel in it (weighs more), and has less holes punched out.

Cheers,

Beware of Husqvarna Garden Tractors! (and TS354, TS348, etc).