You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MF 1450

- Thread starter MFDAC

- Start date

It was right at 50 bucks shipped, Gary. Hope they hold up like yours have! Local store website always said they had them in stock but when I would go, they were out.Hey Doug what do they get for that set now days? I have a set of of 5 I bought over 40 years ago and have used them lot & lots have really served me well, I think I got them from HF when just about everything came out of Calif

DAC

That's a good price, when I got mine it said somewhere that they were made in India and several guys laughed and said have fun with those but they cut thur steel as or better than a lot of bits I've had, I'm not the best at sharpening bits so the 1" doesn't as good as it should I step drill for 1"It was right at 50 bucks shipped, Gary. Hope they hold up like yours have! Local store website always said they had them in stock but when I would go, they were out.

DAC

Last edited:

We bought a similar set over 15 years ago and most still drill. But 5/8 and 3/4 almost not fit to use as the end and sides of the flutes toward cutting end worn to a very slight taper causing them to bind if drilling thick stuff. But have great service for the money!

After I got the BBQ grill fiasco done today, it was time to tinker with the 1450 for awhile.

I really dislike everything about how the hood and grill mount, and ties down. I probably shouldn't mess with it but I don't like those little bungee cord latches at least the way they are. It takes both hands and a pair of channel locks to hook each cord. Gotta be a better way and still hold it down tight.

I'm thinking about just the hood and sides tilting without the grill. Mount the grill firm on the chassis with some internal structure to mount a pivot on. Also thought about removing the sides even. Not out of the question yet! Roughed in a possible scenario tonight.

I have no brilliant ideas about a hold down of some type yet though---LOL!

DAC

I really dislike everything about how the hood and grill mount, and ties down. I probably shouldn't mess with it but I don't like those little bungee cord latches at least the way they are. It takes both hands and a pair of channel locks to hook each cord. Gotta be a better way and still hold it down tight.

I'm thinking about just the hood and sides tilting without the grill. Mount the grill firm on the chassis with some internal structure to mount a pivot on. Also thought about removing the sides even. Not out of the question yet! Roughed in a possible scenario tonight.

I have no brilliant ideas about a hold down of some type yet though---LOL!

DAC

I am committed to building this tilt up now. I cut the grill mounting studs off the hood except for the two that it is pivoting on. Gonna take some messaging but it will open and close how I was thinking. Also thinking that using a Dzus type fastener to hold the hood at the back on the top of the dash. I'll put some kind of cushion between the hood and the dash.

DAC

DAC

I bought some self adhesive felt pads to use on a few of my projects. Here they are on the elec-trak. They keep the hood from scratching the paint and help with any vibration.I am committed to building this tilt up now. I cut the grill mounting studs off the hood except for the two that it is pivoting on. Gonna take some messaging but it will open and close how I was thinking. Also thinking that using a Dzus type fastener to hold the hood at the back on the top of the dash. I'll put some kind of cushion between the hood and the dash.

DAC

View attachment 41222 View attachment 41223

Attachments

Yes Gary, we used them a lot on dirt track race cars through the years. We would want a few of the body parts removable and they were a clean, durable way to do that. Is there a reason why I shouldn't use them? You are an aviator so maybe there is something I'm overlooking.Hey Doug just one quick question do you have experience with Dzus fasteners?

Those look like they work great Rick! Thanks for the tip! I'm not going to be real concerned about scratching but I hate rattles!I bought some self adhesive felt pads to use on a few of my projects. Here they are on the elec-trak. They keep the hood from scratching the paint and help with any vibration.

DAC

I got sidetracked on cleaning the office in my shop but did get a little started on the hood and grill mount. Found an old automotive "x" brace that had some bolt mounts and cut them off. Drilled a 5/15" hole on both sides of the frame and bolted them into position so I can build a mount on the grill end.

DAC

DAC

I missed last night. I was working on the 1450 but also had the Southern 500 on TV. When the race got over it was time to go hit the shower!

Got the basic hood tilt done, waiting on some latches for hold downs. Going with simple "turn latches rather than Dzus fasteners. Getting into a hurry up and get it out of the shop mode for awhile. Winter's coming and I have 3 vehicles that need to come in for service and repairs. Need to change oil, grease zirks, check gear lube and just check out the MF8E to be sure it's ready for snow plowing. The 1450 is going to stay ugly for now, maybe forever---LOL!

Got the grill supports welded up and test fitted last night.

Can't see much of them with the hood closed.

This upholstery retainer channel was still on the old seat so I'll cut it up for some trim in places. Not sure what it is actually called.

Painted and installed the grill supports this afternoon.

DAC

Got the basic hood tilt done, waiting on some latches for hold downs. Going with simple "turn latches rather than Dzus fasteners. Getting into a hurry up and get it out of the shop mode for awhile. Winter's coming and I have 3 vehicles that need to come in for service and repairs. Need to change oil, grease zirks, check gear lube and just check out the MF8E to be sure it's ready for snow plowing. The 1450 is going to stay ugly for now, maybe forever---LOL!

Got the grill supports welded up and test fitted last night.

Can't see much of them with the hood closed.

This upholstery retainer channel was still on the old seat so I'll cut it up for some trim in places. Not sure what it is actually called.

Painted and installed the grill supports this afternoon.

DAC

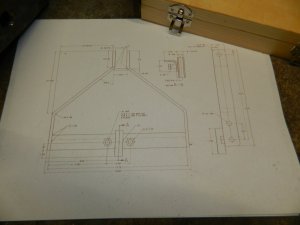

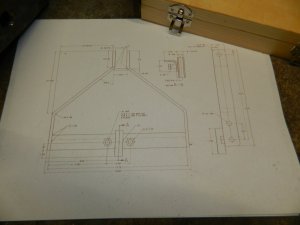

Started on the 3 point a-frame this afternoon. Trying to get it functional for at least moving my trailer around the yard. Since I have no experience with a cat0 3 point, I'm probably approaching it all wrong. Just building it for my needs I guess.

Using the dimensions from the drawings Kenny sent me and trying to use materials I have on hand, I think this stuff might work without spending a fortune on new materials. Dimensions will be the same as the drawing, but it's gonna look different. My biggest deal is I want a female hitch receiver on it. The implement hitch tube is actually a wrist pin out of a late 1950's GMC 270 engine. Measures correct but is a quarter inch shorter. I'll make that work. Center hole is 11/16". Almost the same as the drawing. Need to get another 5/8" nut.

DAC

Using the dimensions from the drawings Kenny sent me and trying to use materials I have on hand, I think this stuff might work without spending a fortune on new materials. Dimensions will be the same as the drawing, but it's gonna look different. My biggest deal is I want a female hitch receiver on it. The implement hitch tube is actually a wrist pin out of a late 1950's GMC 270 engine. Measures correct but is a quarter inch shorter. I'll make that work. Center hole is 11/16". Almost the same as the drawing. Need to get another 5/8" nut.

DAC

Your having lots of fun today Doug. Ya busy times. I’ve got a bunch of tractors to get ready for winter, 4 or a little more cords of wood to cut, spilt and stack. And 5 sixty foot rows of potatoes to dig, sort and store somewhere. And other little things to do. Case 224 and attachments is one of them. Hehe. Busy busy.

Noel

Noel

Ought to work.Started on the 3 point a-frame this afternoon. Trying to get it functional for at least moving my trailer around the yard. Since I have no experience with a cat0 3 point, I'm probably approaching it all wrong. Just building it for my needs I guess.

Using the dimensions from the drawings Kenny sent me and trying to use materials I have on hand, I think this stuff might work without spending a fortune on new materials. Dimensions will be the same as the drawing, but it's gonna look different. My biggest deal is I want a female hitch receiver on it. The implement hitch tube is actually a wrist pin out of a late 1950's GMC 270 engine. Measures correct but is a quarter inch shorter. I'll make that work. Center hole is 11/16". Almost the same as the drawing. Need to get another 5/8" nut.

DAC

View attachment 41859 View attachment 41860 View attachment 41861

Thanks for the pictures, Jason! I may finish building the one I started for the sleeve hitch and build another for the receiver. I think I have enough square tubing to do that! I'll just use the dimensions on Kenny's drawings but build it in the upside down "T" shape instead of "A" shaped.So are you wanting sleeve hitch or a receiver hitch (or both ) Doug? The heavy hitch style can be made with or without the weight brackets. Here's one I made. Second pic shows it modified with 2 receivers.

DAC

I changed my mind again---LOL! Using the dimensions on the drawings, I decided that a slide in sleeve hitch for the receiver will work---maybe! I cut up a bunch of steel and have gotten a frame tacked together stealing some of Jason's ideas.

First, the pins were tacked in the channel

Then this Reese 40" extension got cut up. Got it out of scrap a lot of years ago.

That powder coat that Reese uses is tough! It melts like plastic when grinding areas for welding.

First I put a new blade in the old chop saw. I bought a few boxes of blades way back about 15 years ago when The saw was new. The new one is the last one from all them. Guess all HF stuff isn't Chinese. I noticed this on the blade that was removed.

This is the tacked together result.

Still going to box the channel as It's getting welded up. Hopefully it will move a empty trailer!

Will build a new upper link too. Thinking that an automotive tie rod will work. Got a lot of almost new ones from the racing days.

DAC

First, the pins were tacked in the channel

Then this Reese 40" extension got cut up. Got it out of scrap a lot of years ago.

That powder coat that Reese uses is tough! It melts like plastic when grinding areas for welding.

First I put a new blade in the old chop saw. I bought a few boxes of blades way back about 15 years ago when The saw was new. The new one is the last one from all them. Guess all HF stuff isn't Chinese. I noticed this on the blade that was removed.

This is the tacked together result.

Still going to box the channel as It's getting welded up. Hopefully it will move a empty trailer!

Will build a new upper link too. Thinking that an automotive tie rod will work. Got a lot of almost new ones from the racing days.

DAC

That’ll work fine Doug