This the back side of a quick fixture that I made up to adjust and test the coils.

The positive clamp from the battery charger will be connected to the wire on the big brass plate on the bottom.

The ground clamp will be connected to the smaller brass plate on the side.

The coil is set into this fixture and it is clamped in a vice to hold the coil tight to the contact points and the battery charger clamps are hooked up.

When I touch the wire from the ground clamp to the upper contact on the coil, it produces a spark.

It's kind of hard to see here but there is a nice hot spark jumping between the open points on the spark tester.

This is a view of a vaporizer carb taken apart. This shows the back side of the float bowl and the vapor manifold above it. The bolts on over the open space on the side of the exhaust manifold with a this tin cover plate in between them. The fuel flows up across that tim plate that is heated to 600 degrees by the exhausts on the other side of it. As soon as the liquid fuel touches that tin plate, it is instantly vaporized. This fuel vapor is then drawn up to the air valve on top of the manifold where it is mixed with the air to flow into the cylinders.

I have never worked on the vaporiser carburetors that were available on the newer 1926 and 1927 Ford model-T but from what I've read on the internet, it is very important not to have any vacuum leaks. So I used the red heat resistant RTV sealer on both sides of the thin vaporizer plate when bolting it back onto the manifold and also on the tubes going in and out on the float bowl and manifold.

I got the engine running but it runs very rough. When I pulled the spark plugs they were all covered with a thick black soot so it is running way too rich.

The instructions on the internet say to have the mixture screw on the top of the float bowl turned out 1-1/4 to 1-1/2 turns, which I did. After checking and cleaning the plugs. I turned this mixture screw all the way in to close it up completely and plugs are still soot covered the same as before.

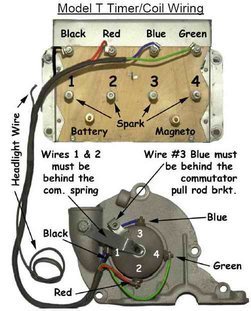

This is the firing order for the model-T. The commutator ( distributor cap ) is mounted right on the front of the camshaft. To time the commutator, you set the distance of 2-1/2 inch between the center of the pullrod on the commutator and the center of the bolt to the left of it the holds the retaining strap in place. This is set as specified.

Checking the spark at the top of the spark plugs shows the all four coils are putting out a nice hot spark and obviously the spark plugs are fouling out from the over rich gas mixture.

So ... after showing the owner what I've got, we have decided to remove this intake and exhaust manifold and go back to this regular intake and exhaust manifolds and carburetor that Ford used on the model-T's from 1909 thru 1927.

We are doing this for two reasons. First, even if this carburetor had worked fine, that thin vaporizer plate only last about three or four years and has to be replaced. Second, the regular style carburetors have worked just fine on millions of model-T's for hundreds of years.

Obviously, Henry wasn't satisfied with the newer vaporizer carb system because he went back to the regular updraft carb system on the model-A's.