Thanks for all the comments and ideas, guys! I will try to set up the air line similar to what you suggest, Stew, but I can't get 25 feet.

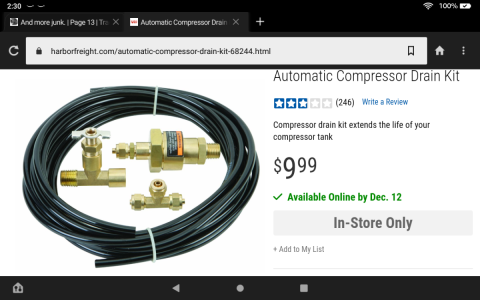

I almost bought the HF air drain kit a couple times, Bill, but since I drain the tank after every use I didn't buy it yet. Still might have to do that! We have a lot of what I think are called "twin screw" air compressors at work. All of them have the electric drains on them. They all run 24-7, never shut off. For the most part the electric drain valves are very reliable. There is one Atlas Copco that seems to go through those drain valves quite often.

On the rubber pads, one of the young guys at work was assigned to a job last spring where some heavy rubber sheets 3/4" thick had to be cut and laid in an area for weed control. It was an "experimental" test. Needed something the wind wouldn't tear apart. Anyway when he got done, they told him to throw away the scraps. It's expensive stuff and he stashed the scraps instead and told me where to get a 4"x 4' piece of it! Management scrapped the idea even though it seems to work pretty well as being too expensive. I don't know what it's called but it kinda looks like it might be shredded tires or something. I cut 3-4"x 4" squares, slid them under the tank feet and plugged the compressor in. Marked the floor to see if it moved. Didn't move a bit!

Might not have to drill the floor to bolt it down!

Then I put the regulator together with quick connects for now. Plugged it in and adjusted it to 90 psi. I will have to reverse the pressure switch and outlet for the location it looks like the compressor will have to go. I also cut and removed that wire that was holding the pop-off valve closed, and it is holding too. This corner with a bunch of junk in it will be its home. The cart with the bench grinder and belt sander on it will have to go somewhere else and the drill press will need to move to the right in its place. Coat rack and some other junk in there will have to go away.

Obviously, I can't simply put it where the old compressor was---LOL!

I'll keep hammering away at it when I have time! Need to get the compressor moved soon though, as I have some vehicle maintenance to do, and it and the windmill are blocking that space! The windmill can just lay in the gravel between the shop and the camper.

DAC