Yeah Noel, Junk is a good thing in my opinion! I just need to keep the majority out sight from the house so Loree doesn't complain!It’s coming along Doug. I sure get a kick out of all the good junk ya drag home. Hehe.

All comes in handy. I’ve got good junk around too. Ya never know what might come in handy.

Noel

The guy that taught me carpentry used to say "That is so crooked the smoke would go down if you burnt it"---LOL!The last time I tried buying lumber at our store it took forever to come up with enough wood that was useable. The rest was only good for making sawdust. I was so disgusted that I swore I wouldn't buy anymore there. Plywood, OSB and such would probably be fine.

Those look like feasable ways to build a container/shop! I like the two container setup with trusses, Aaron! Great storage! It would be even better if doors were on the containers facing into the shop area to so it could be entered from in the shop!

That is one thing my wife has said would be acceptable is a shipping container, Roger. She doesn't seem to care what they look like. I have enough materials laying around here to build a nice size shed though. Need to start thinking about building it as my two smaller sheds are about done for.

The lift is operating! I decided to throw away those chinese instructions and ignore the order of assembly. Leave it to them to make 3/8" bolts with an 11/16" head and a 5/8' nut---LOL!

I went ahead and hung the control unit and hooked up the hoses. My plan was to vise grip and bungee cord the locks open so it could be lowered on to the casters. If I could roll it, then the lock rod installation would be easy. Filled it with oil and gave it a try. Took a minute to fill the system but it took off to point where I could open the locks.

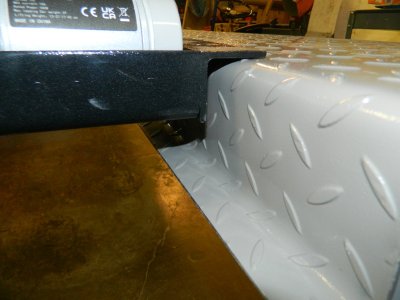

Built the caster frames, installed them and lowered the lift. The frames need some deburring as they can catch the post foot plates being sharp-edged but they raise the posts about a half inch!

Then I figured I may have to put a come-along on it to move it. WRONG! It rolls super easy but bending over that far to push or pull is kinda hard on an arthritic back. Got the rods shoved in from both ends and raised the lift up where It can be walked under to do the hookup and adjustment. Called it quits at that point.

Also a floor jack cross beam I ordered arrived today. I'm hoping to be able to adopt it to a 3 ton electric scissor lift I also have coming.

I'm getting a short-timers attitude at work. I have plenty of vacation time so I took the next 3 days off. I don't feel like shoveling s-word all day for 3 days which is what would happen! Maybe not shoveling the whole time but would be out in it most of the time. I will go in Friday as the s-word is supposed to stop and we are shorthanded.

DAC