Kinda what I was thinking too.

I packed thin wall pipe with sand too. For minor bends nothing extreme. Just have find a way to plug the ends..

I was thinking the same thing Bill, as I started reading this.

Noel

Kinda what I was thinking too.

I packed thin wall pipe with sand too. For minor bends nothing extreme. Just have find a way to plug the ends..

I'm afraid the cable wouldn't pull back out, Chris. Had a conduit bender at work, but I ain't there anymore---LOL!Try putting a short piece of cable or something like that inside before you bend it. Know anyone with a conduit bender?

Kinda what I was thinking too.

I packed thin wall pipe with sand too. For minor bends nothing extreme. Just have find a way to plug the ends..

I was thinking the same thing Bill, as I started reading this.

Noel

I may have come up with a way to use this tube, but for curiosity, does the one you have look like this one, Ted?DAC I still have the fill tube in the parts 1450 transaxle if you need it.

It looks just like that one. fyi mine is facing forward. It is still in the unit I have not taken it out yet.I may have come up with a way to use this tube, but for curiosity, does the one you have look like this one, Ted.

Your setup is just like the service manual then Ted. There must have been variations in the pan mount and other things through the years of this series of tractors. This tractor is a 1978. Sounds like I would have needed to buy a lot more from your parts tractor than I did to make things fit right!It looks just like that one. fyi mine is facing forward. It is still in the unit I have not taken it out yet.

That would have opened up a whole nuther can of worms, Jim. I would have needed to use longer bolts at the rear. Sounds simple except---The bolts go through the seat slider bottom rail and both rails of the seat slider are bent and won't move to pull the old bolts and install new ones.Can you shim your fender pan up a little to avoid cutting it out. I’ve seen several guys do that for another inch for tire clearance.

`

`

Here is a link to the owners manual for the generator itself if you don't have a copy -Been piddling around in the shop, finishing the edges of that sign and other small things. Decided I better learn a bit about that generator I got last May, and see what I might need to do for a backfeed cord in case of power outages. Probably should have an old electrician I know set up one of those transfer switches that I can plug in outside. but it won't energize the house until the main braker is shut off.

View attachment 75572 View attachment 75573

View attachment 75574

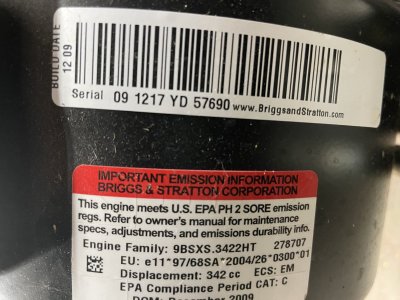

Can't find any info on the engine that is accurate. The engine model and type number are obsolete on B/S website. 342 cc on the sticker. Would like to know the power specs but these more modern engines are top secret it seems---LOL!

Numbers on valve cover.

View attachment 75577

Those numbers get hits for parts, but I sure couldn't find any accurate specs.

Built in December of 2009. I have read 342cc could be anywhere between 10-14 HP! I'm thinking more like 10.

View attachment 75578

The generator model number.

View attachment 75576

Guess I don't really need to know exactly what it is, but it would satisfy my curiosity---LOL!

DAC

Thank-you, Stew! I never had a clue this may have come from Sears! I suppose the numbers indicate that, but nothing on it says Sears anywhere. That manual will be helpful!Here is a link to the owners manual for the generator itself if you don't have a copy -

Briggs & Stratton 030430 generator manual

Thanks Noel. One of the sites I looked at said 11.7 HP so that guess was the closest to what you got!I figure about 11 hp Doug.

Noel

I think these are the owners manual and parts list for the engine.Thank-you, Stew! I never had a clue this may have come from Sears! I suppose the numbers indicate that, but nothing on it says Sears anywhere. That manual will be helpful!

Thanks Noel. One of the sites I looked at said 11.7 HP so that guess was the closest to what you got!

Just did some painting and cleaning around the shop, and also some historical computer searching today.

DAC

Thanks again, Stew! Hope I never need major parts but got the links on file!I think these are the owners manual and parts list for the engine.

No Chris, that pic was the Apple wallpaper already installed on the computer. Nowhere's near that good of a photographer---LOL!Pretty photo. Did you take it?