Don’t we all lolYou need a mill.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And more junk.

- Thread starter MFDAC

- Start date

I've got one of these because of space limitations. It is not the perfect solution but I have done a ton of work on it. The repair done on the oil filter housing was completed with this. My Nephew purchased it for a customers engineering project and then sold it to me for pop money. I think it came with just about every tool and accessory available and to this day I don't think I've opened all the boxes.

I really like the 13 inch swing but it does have it's limitations and when fabricating something you need to keep that in mind.

Would I buy another New? No. You can purchase some high quality used machines for what one of these cost new.

I really like the 13 inch swing but it does have it's limitations and when fabricating something you need to keep that in mind.

Would I buy another New? No. You can purchase some high quality used machines for what one of these cost new.

That is a great looking machine, Chris! Even if I could afford one and found space, then I would take forever for me to learn how to use it! I've always been kind of dense but it's getting worse with age---LOL!

Got the running around done, I have to go into Rapid every Monday for an allergy shot. Fortunately, I only have to deal with city traffic for about a mile! I can take back roads almost all the way there. That is the south end of town and there is more development going on but with the dump right at the southern end of the street the doc's office is on that will stop most of the development eventually! I hate being in the city too.

Got back home, ate lunch and did some in house chores so all I got done in the shop was truing up those pucks a little more square. they are ready to install now. Didn't take any pics. Should be able to at least start assembly tomorrow. I almost said "those puckers"---LOL!

DAC

Got the running around done, I have to go into Rapid every Monday for an allergy shot. Fortunately, I only have to deal with city traffic for about a mile! I can take back roads almost all the way there. That is the south end of town and there is more development going on but with the dump right at the southern end of the street the doc's office is on that will stop most of the development eventually! I hate being in the city too.

Got back home, ate lunch and did some in house chores so all I got done in the shop was truing up those pucks a little more square. they are ready to install now. Didn't take any pics. Should be able to at least start assembly tomorrow. I almost said "those puckers"---LOL!

DAC

Got started on assembly of the brake. Even tho it is a pain, I did a test fit first to make sure I shaved enough off of the pucks.

Feels like the disc will float well so it was time to JB Weld the inner puck in. There just isn't enough meat around the cavity to trust it without the JB Weld.

Put the caliper together after cleaning the pins and pin holes. Put a little anti seize on the pins since they had to be driven out with a punch.

Going to let the JB Weld cure overnight. Don't need to knock that inner puck out of the hole trying to assemble this setup in such tight quarters.

DAC

Feels like the disc will float well so it was time to JB Weld the inner puck in. There just isn't enough meat around the cavity to trust it without the JB Weld.

Put the caliper together after cleaning the pins and pin holes. Put a little anti seize on the pins since they had to be driven out with a punch.

Going to let the JB Weld cure overnight. Don't need to knock that inner puck out of the hole trying to assemble this setup in such tight quarters.

DAC

The brake job from he!! is getting closer to being done. I hope this doesn't have to come back apart in my lifetime---LOL! Got the disc and caliper assembled and the linkage hooked up on the caliper end. Hindsight I should have attached the brake return spring to the caliper arm before the caliper went in. It was quite a battle with a few words that---you guessed it, rhymes with "puck" to find an angle to get it though the arm mount hole. That was before I pulled the pickle fork that had the frame rail spread about 3/4"! It would have been impossible to get this stuff back together without spreading that out.

Think I will cut a piece of 1/8" aluminum plate to go across the void left by removing the rear PTO.

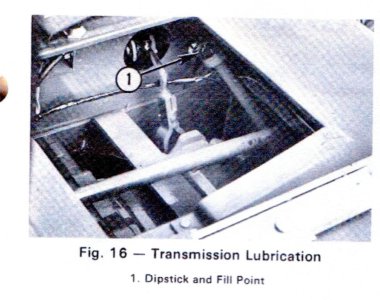

Since the left frame rail was bolted back to the transaxle, a long overdue part from Daniel got installed. The transaxle dipstick tube! Screwed it in to place and shoved the dipstick that Ted sent into it and the oil level is just a hair over full! Thought it should be right since the transaxle got filled to the specs I found on TractorData, and I've not seen any leaks since putting a new front seal in.

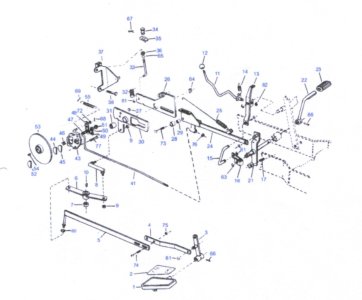

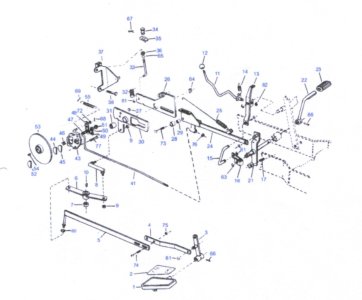

Pinned the 3 point hydro cylinder back into place but called it a day to go look at a diagram of the forward end of the brake linkage.

It was cobbled up with 4 or 5 oversize nuts on it as spacers before the adjuster nut. the diagram shows just the nut belongs there. #76.

Pushed the brake pedal and the linkage slides through and the adjusting nut should pull the link just fine now. Will hook that together tomorrow and maybe do some more assembly.

DAC

Think I will cut a piece of 1/8" aluminum plate to go across the void left by removing the rear PTO.

Since the left frame rail was bolted back to the transaxle, a long overdue part from Daniel got installed. The transaxle dipstick tube! Screwed it in to place and shoved the dipstick that Ted sent into it and the oil level is just a hair over full! Thought it should be right since the transaxle got filled to the specs I found on TractorData, and I've not seen any leaks since putting a new front seal in.

Pinned the 3 point hydro cylinder back into place but called it a day to go look at a diagram of the forward end of the brake linkage.

It was cobbled up with 4 or 5 oversize nuts on it as spacers before the adjuster nut. the diagram shows just the nut belongs there. #76.

Pushed the brake pedal and the linkage slides through and the adjusting nut should pull the link just fine now. Will hook that together tomorrow and maybe do some more assembly.

DAC

It was such a nice day the MF1450 got no attention. Decided I better do some outside work. Leaves had built up real bad on the east side of the shop where the camper, Craftsman GT5000 and the Gardenway LT sits. I had already moved the GT5000.

Don't need big leaf piles on the gravel then s-word on top of them since this is the downwind side of the shop.

Both those tractors fired right up so got them moved and raked the leaves into a pile.

Had the overhead door open for several hours today!

Put the leaf pile into the yard cart and took them to the front yard to dump.

There were a few more areas to clean up like on the concrete areas. Leaves needed to be raked or blown out of several areas. Don't need leaves under s-word where the walk behind snow blower will be used. 2 more loads with the cart. Then I unhooked the cart and started mowing the leaves and twigs. This guy was sitting on a tractor at the next door lady's place but do you think he would lift a paw to help?---LOL!

Was in a hurry as the downwind neighbors probably didn't appreciate the dust at all. It was really bad! Somehow, somewhere along the way, I felt a "stab" in my left forearm and then left ear. Something flew out from under the tractor and smacked me pretty good. Both drew blood but I didn't know it until i was done and wiping off a bit. It's a right side discharge so I have no clue how something got me in the left side. Ear started bleeding again soon as I wiped the dirt out of it and the dang thing didn't want to stop for a bit. Probably took 20 minutes or so!

My back took a beating so that was enough for today.

DAC

Don't need big leaf piles on the gravel then s-word on top of them since this is the downwind side of the shop.

Both those tractors fired right up so got them moved and raked the leaves into a pile.

Had the overhead door open for several hours today!

Put the leaf pile into the yard cart and took them to the front yard to dump.

There were a few more areas to clean up like on the concrete areas. Leaves needed to be raked or blown out of several areas. Don't need leaves under s-word where the walk behind snow blower will be used. 2 more loads with the cart. Then I unhooked the cart and started mowing the leaves and twigs. This guy was sitting on a tractor at the next door lady's place but do you think he would lift a paw to help?---LOL!

Was in a hurry as the downwind neighbors probably didn't appreciate the dust at all. It was really bad! Somehow, somewhere along the way, I felt a "stab" in my left forearm and then left ear. Something flew out from under the tractor and smacked me pretty good. Both drew blood but I didn't know it until i was done and wiping off a bit. It's a right side discharge so I have no clue how something got me in the left side. Ear started bleeding again soon as I wiped the dirt out of it and the dang thing didn't want to stop for a bit. Probably took 20 minutes or so!

My back took a beating so that was enough for today.

DAC

Hope it’s nothing serious Doug that is strange you got hit on the opposite side of the discharge. My blood is thin sometimes I look like I’m ready for the ER and never realized I was injured. The tractors look like a good working team for you. My neighbor has three Craftsman GT 5000. They are all the dark green ones. I’ve been trying to get him to sell me one but he won’t.Ear started bleeding again soon as I wiped the dirt out of it and the dang thing didn't want to stop for a bit. Probably took 20 minutes or so!

My back took a beating so that was enough for today.

DAC

Does your neighbor have a BB gun?It was such a nice day the MF1450 got no attention. Decided I better do some outside work. Leaves had built up real bad on the east side of the shop where the camper, Craftsman GT5000 and the Gardenway LT sits. I had already moved the GT5000.

View attachment 75131

Don't need big leaf piles on the gravel then s-word on top of them since this is the downwind side of the shop.

Both those tractors fired right up so got them moved and raked the leaves into a pile.

View attachment 75132

Had the overhead door open for several hours today!

View attachment 75133

Put the leaf pile into the yard cart and took them to the front yard to dump.

View attachment 75134

There were a few more areas to clean up like on the concrete areas. Leaves needed to be raked or blown out of several areas. Don't need leaves under s-word where the walk behind snow blower will be used. 2 more loads with the cart. Then I unhooked the cart and started mowing the leaves and twigs. This guy was sitting on a tractor at the next door lady's place but do you think he would lift a paw to help?---LOL!

View attachment 75139

View attachment 75137

Was in a hurry as the downwind neighbors probably didn't appreciate the dust at all. It was really bad! Somehow, somewhere along the way, I felt a "stab" in my left forearm and then left ear. Something flew out from under the tractor and smacked me pretty good. Both drew blood but I didn't know it until i was done and wiping off a bit. It's a right side discharge so I have no clue how something got me in the left side. Ear started bleeding again soon as I wiped the dirt out of it and the dang thing didn't want to stop for a bit. Probably took 20 minutes or so!

My back took a beating so that was enough for today.

DAC

I'm more interested in knowing more about the old truck !It was such a nice day the MF1450 got no attention. Decided I better do some outside work. Leaves had built up real bad on the east side of the shop where the camper, Craftsman GT5000 and the Gardenway LT sits. I had already moved the GT5000.

View attachment 75131

Don't need big leaf piles on the gravel then s-word on top of them since this is the downwind side of the shop.

Both those tractors fired right up so got them moved and raked the leaves into a pile.

View attachment 75132

Had the overhead door open for several hours today!

View attachment 75133

Put the leaf pile into the yard cart and took them to the front yard to dump.

View attachment 75134

There were a few more areas to clean up like on the concrete areas. Leaves needed to be raked or blown out of several areas. Don't need leaves under s-word where the walk behind snow blower will be used. 2 more loads with the cart. Then I unhooked the cart and started mowing the leaves and twigs. This guy was sitting on a tractor at the next door lady's place but do you think he would lift a paw to help?---LOL!

View attachment 75139

View attachment 75137

Was in a hurry as the downwind neighbors probably didn't appreciate the dust at all. It was really bad! Somehow, somewhere along the way, I felt a "stab" in my left forearm and then left ear. Something flew out from under the tractor and smacked me pretty good. Both drew blood but I didn't know it until i was done and wiping off a bit. It's a right side discharge so I have no clue how something got me in the left side. Ear started bleeding again soon as I wiped the dirt out of it and the dang thing didn't want to stop for a bit. Probably took 20 minutes or so!

My back took a beating so that was enough for today.

DAC

Yeah kind of strange for sure, Jim! Maybe there is something to Rick's theory---LOL! I have a small cut on the outer lobe of the left ear, and a deep scratch about 1-1/2" long on the bottom of the left forearm. I don't think I would buy a GT5000 like this as the deck doesn't float. Since I got it free, I felt putting a few bucks into it to get it running would be good. Got about $150 into it now. It handles some of the work I need to do around here, and makes a good backup mower and yard cart hauler.Hope it’s nothing serious Doug that is strange you got hit on the opposite side of the discharge. My blood is thin sometimes I look like I’m ready for the ER and never realized I was injured. The tractors look like a good working team for you. My neighbor has three Craftsman GT 5000. They are all the dark green ones. I’ve been trying to get him to sell me one but he won’t.

That is a 1955 GMC, Brett. Got it in non running, no title condition in 2009. It was going to be scrapped. It's no hot rod. It's my time machine. Besides the stereo, it's still just like driving in 1955.I'm more interested in knowing more about the old truck !

View attachment 75175

The day I got it.

It hadn't been run since 1997.

Finally got a title and license in 2011. Been a semi daily driver ever since. Way to long of a road to being a driver to discuss here.

Couple more pics through the years.

10 years ago pulling a parade float.

Won a "Ugly truck Award" in 2015. It paid a hundred bucks too.

Just driving around.

Sorry to be so long of a story, but you asked, Brett---LOL! I've got 2 other "newer" GMC's, a 1972 we have owned since 1979 and a 1970 Jimmy project my Mom bought in 1971.

Back to tractors. There was a couple of unexpected things that got in the way today but I did get the brake linkage hooked up on the MF1450. The park brake grabs fine too. Will do the assembly maybe tomorrow, but I think Loree has other ideas. May end up working on it Sunday while watching the race.

DAC

Still had some distractions today, but later afternoon I got to get in the shop and try to work on the MF1450. One step forward and 3 steps back again. Can't seem to catch a break with this thing.

I tried to install the fender pan mount. Nope not happening. The dipstick tube won't let it drop into position to bolt it on.

The tube came from a 1450 as well as the dipstick. Maybe I will just notch the pan mount like this.

But then reaching the dipstick is still blocked by the fender pan. X marks about where the cap will be.

Suppose I can just as well cut that opening below the seat bigger too. Got disgusted and called it a day before it really got started.

Instead of cutting a aluminum plate to cover the back of the transaxle I just as well use this plate that is ready to go.

DAC

I tried to install the fender pan mount. Nope not happening. The dipstick tube won't let it drop into position to bolt it on.

The tube came from a 1450 as well as the dipstick. Maybe I will just notch the pan mount like this.

But then reaching the dipstick is still blocked by the fender pan. X marks about where the cap will be.

Suppose I can just as well cut that opening below the seat bigger too. Got disgusted and called it a day before it really got started.

Instead of cutting a aluminum plate to cover the back of the transaxle I just as well use this plate that is ready to go.

DAC

Thanks Jim. It would be harder to get at turned a half a turn. This pic from the operator's manual shows it pointing forward but clocked a bit to clear the rear pto shaft.The further the tube gets turned would cause more clearance trouble, either direction.I think that dip stick tube needs to be turned a half turn. I love the truck looks a sleeper. Guys work very hard to get that vintage look.

Glad you like the truck, but it is faaaarr from a sleeper---LOL! Sleepy, maybe! The mid 1960's Chevy 230 that someone transplanted into it well before I got the truck is just a nice smooth engine. The truck originally would have had a GMC designed 248 six banger.

DAC

This tractor is looking like a bad design! Built to only be taken to a dealer, then so difficult the dealer charges crazy repair prices!That’s a bad design on that dip stick. That would be a pain to check the oil. Cutting out the plate would work good.

DAC

Is it keeping you awake at night. Right about now I think I'd be going nuts. You know they got it together the first time.

That pipe needs another bend in it between the threads on the end and the bend that's there now. Either that or cut the pipe in that spot, Thread the ends and put a union in there.

That pipe needs another bend in it between the threads on the end and the bend that's there now. Either that or cut the pipe in that spot, Thread the ends and put a union in there.

It don't keep me awake at night, but it's pretty annoying, Chris! I just watched the race today, didn't work on a dang thing! If that bend would have been lower the dipstick tube would have fit. No clue why it doesn't fit this tractor right. Think what I will try to do is make a lower bend in the tube. Guess if I collapse it at least I tried something. Will have to get out the blue wrench and give it a shot!

DAC

DAC

Kinda what I was thinking too.Know anyone with a conduit bender?

I packed thin wall pipe with sand too. For minor bends nothing extreme. Just have find a way to plug the ends..