I sure used to like slot car racing. We were lucky and had a nice track not far from where I grew up. If I remember correctly it was 25 cents an hour to use the track and had 6 lanes. I think if there was one around here I'd still be doing it. There was something invigorating about pushing down that plunger with your thumb and seeing the car take off.

I know what you mean, Chris, push that plunger and all of a sudden you are in control of a very fast piece of equipment that you have actually worked to pay for! Spent all my money I got fixing and painting fences for our trailer park owner on a bicycle one summer then slot cars and model cars the rest of the childhood summers before 1972. I actually got some slot car stuff pretty cheap and free lap time at a big 1/24th scale track downtown. Mom was recently divorced, and the owner of the track was kind of sweet on her! Lucky me!

Nowadays all the controllers are pistol grip type, with a big heat sink and knobs sticking out of the top of them.

Quite a track Doug. Lots of trophy’s. Grave stones are looking good. Would quite a job to fix the hail damage on the car.

Noel

Thanks, Noel. That track was factory built by the biggest HO Scale car manufacturer back in the '60's and '70's, Aurora. My brother-in-law owns one of those tracks too, and it is the same one that was at the hobby shop we raced at as kids.

A little over 2500 bucks damage to her car. It will go into the body shop December 18th.

Th grave stones look good and will last a long time. I know a few stone masons and some of the epoxy they use is far better than mortar.

Me and two other guys grew up together. We all had slot car tracks but one of my friends dad had a four lane HO scale track that was huge. We were only allowed to race on that supervised. We had a local 1/24th scale track at our local hobby shop about 15 minutes by bicycle from home. Like Chris mentioned it was 25 cents an hour. We had to have our own controllers that plugged into their tracks. The most popular controller was the Cox brand. The cars now days are so fast it’s hard to see them racing.

The epoxy should work fine, long as water doesn't get under the granite somewhere, freezing and cracking them. I wanted to help in installation and removal of the old ones but Loree's hardheaded 82-year-old uncle wouldn't tell me when he was going up there. He just said "you done enough". Next thing I knew they were done!

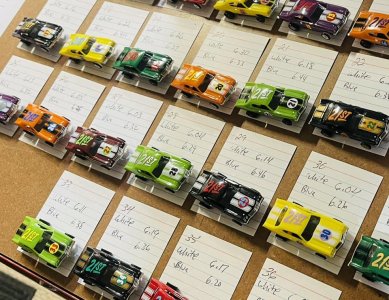

That sounds like me and my friend back in the day, Jim! He had the paper route and I did work like I said above. That friend became my brother in law in the early '80's. The 1/24th track was our main race place as our plan was start with HO's, move up to 1/24th, then eventually on to real race cars! We even did it! We could rent the controllers if we didn't buy one, and of course both of those hobby shops had large inventories of cars and parts. In the 1990's Tyco made HO scale cars we would call "No Seeums" as with the magnetic downforce and choosing the right tire diameters, they were darn hard to see they were so fast! Getting the right tire sizes was the trick though. Sometimes you wouldn't even know your car was de-slotted until it hit a wall or the floor, or another driver---LOL! This is one of them.

The body shop I took Loree's car to today is right next door to the local bearing and seal store here. I figured it would be nice and easy to swing in there and buy the half-moon key. Nope they had nothing that size. I just thought heck with it and went to HF and bought a box of metric ones in hopes that something would fit.

Got lucky and found a size that fits well.

The rotor will float back and forth nicely.

Now there may be another big problem! There is nothing stuck in the brake puck cavity. Evidently the rotor wore down the lip around it. Thre isn't much meat to hold the puck in there. Looks like it may get some JB Weld to hold it in the hole!

If it ain't one thing, it's another!

DAC