You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And more junk.

- Thread starter MFDAC

- Start date

Whatever it takes to get money from people! The girls in the family had a 4 or 5 year tradition to go black Friday shopping. They would be at stores openings all dressed alike in crazy colors so they could spot each others in the mobs! Them women were nutcases---LOL! They have all scattered into different states now and don't get together for it like they used to.Our thanksgiving was a month or so ago Doug. Oct 9/23 I think it was. No holiday this week. Funny thing is. All we hear is Black Friday sales here for weeks before and after Black Friday. And it has nothing to do with Canada. As far as I know.

Noel

DAC

Crazy like a fox I'd say. Those girls knew exactly what they were doing.Them women were nutcases---LOL!

Did a small amount of tractor related work today. Got the Gardenway hydro LT and the Craftsman GT5000 ready for winter since they have to sit outside. Got the batteries out of them, brought into the battery bench in the shop and put on maintainers.

This is the second winter on those tractor body bags so we'll see if they hold up one more time! Last year the GT5000 and the MF1450 were under the bags. The 1450 is on the lift this year, so all three Massey Ferguson's are now inside.

It gets a little tight in here with the Denali inside too! We are taking it to Aberdeen Wednesday night so checked it out for the drive, and cleaned up the interior. Still need to clean the inside of the windows.

Still had no luck with the photoshop program for the iMac computer. I think this computer is about 2 years older than the software our daughter left here. It seems like a good machine for what I want just need to find compatible software.

DAC

This is the second winter on those tractor body bags so we'll see if they hold up one more time! Last year the GT5000 and the MF1450 were under the bags. The 1450 is on the lift this year, so all three Massey Ferguson's are now inside.

It gets a little tight in here with the Denali inside too! We are taking it to Aberdeen Wednesday night so checked it out for the drive, and cleaned up the interior. Still need to clean the inside of the windows.

Still had no luck with the photoshop program for the iMac computer. I think this computer is about 2 years older than the software our daughter left here. It seems like a good machine for what I want just need to find compatible software.

DAC

Last edited:

I just covered them up last year with no other precautionary measures, Noel, did the same this year. Western South Dakota climate doesn't really get much chance for condensate under things like this. Low humidity and lots of wind. About the only critter that might try to get under them is a few feral cats that run around here. Since they are sitting on gravel, that helps keep mice and such out of them too.How do the tractors hold up over winter Doug under those tarps ? Do they condensate in there. Do you put bounce dryer sheets or mothballs in there to keep the varmints out ?

Noel

Played phone tag with the house insurance company after I got home from a doc appt and Sam's Club this morning. Finally got out to the shop about 3pm. Built an extension for that 3 point rake on the MF1450.

I didn't worry about being perfectly square as I just put a 3/8" bolt through the adapter tube. Sure didn't need a full size hitch pin. It was a pre built hitch extension I cut some pieces off of to build the 3 point T-Frame out of a couple years ago. Of course that hitch extension came out of the scrap metal trailer at my former job!

I had to raise the overhead door a few inches to put it on the tractor. So windy I didn't even want to do that!

It moves the rakes back about 30" from without the extension, and about 5-1/2 feet from the rear of the tractor. Maybe I will be able to rake leaves away from the driveway culvert out in the ditch in front of the house. Now that the brake should work, might be able to back down into the ditch a bit, lower that contraption and maybe drag out the cottonwood leaves. May not even get tested this fall since I'm so late getting it ready! Raised the lift back up with the rake on it for now. Got some stuff to do getting ready for our drive to Aberdeen on Wednesday afternoon like my laundry tomorrow!

DAC

Thanks, Chris! Unfortunately we will be driving at night. Our son can't get off work early enough tomorrow to drive during the day. We will get in to Aberdeen around midnight. Loree got us an Air B&B at a lake a few miles NW of Aberdeen. Looks like a pretty nice place.Have a safe trip and enjoyable stay.

Hope you have a great Thanksgiving!

DAC

Been doing some shop cleaning and a little welding on a couple of broken wind spinners. Then since the welder was out I decided to work on that yard windmill we got at an auction last winter. The base itself is in pretty good shape but the head is busted and bent. Didn't get before pictures. I welded a chunk of railroad iron upside down to the welding table then ran out of .035 wire! Put some .023 in it to finish until I get into town for another roll. Using the railroad iron for an anvil.

The blades and it's frame is broken off of the hub and spokes. The machine screws holding on the blades don't want to break loose so will probably end up cutting them. They are soaking right now. The tail and pivot shaft was bent up badly. Got that somewhat straightened out.

The roofer and insurance adjuster will be here tomorrow morning to determine getting hail damage repair. Actual work can't happen until late spring but it will be good to have it arranged now.

DAC

The blades and it's frame is broken off of the hub and spokes. The machine screws holding on the blades don't want to break loose so will probably end up cutting them. They are soaking right now. The tail and pivot shaft was bent up badly. Got that somewhat straightened out.

The roofer and insurance adjuster will be here tomorrow morning to determine getting hail damage repair. Actual work can't happen until late spring but it will be good to have it arranged now.

DAC

No never, Chris---LOL! I figured for 15 bucks the windmill would be a good winter job to tinker on. I will use real stakes to hold it down rather than standing it up and poking the legs into the dirt like the previous owner did. Then it laid there for a decade or two being hit by mowers, kids and probably even pickup trucks backing over it! We knew the estate we bought it from. One of my wife's late aunts.

DAC

DAC

I figured and I figured wrong---LOL! I figured if I find the spot the spokes were welded to before, everything should fall into place. Nope! First the tail and pivot sections got straightened, and that went well. I cut all those screws and got the blades off. Took the hub and spokes off the pivot and was able to match the broken welds back where they had been originally. everything seemed to fit pretty well so I figured it would be ok to weld it back together. It's out of round pretty badly so I have to cut it back apart and find out what's going on. Should have taken more measurements before trusting just lining up the original positions.

Roof inspections went ok, insurance company, not so much. We'll see how bad they try to rip us off! They checked the shop roof for damage too. Furnace chimney and weather head is pretty battered he said.

DAC

Roof inspections went ok, insurance company, not so much. We'll see how bad they try to rip us off! They checked the shop roof for damage too. Furnace chimney and weather head is pretty battered he said.

DAC

I got no clue why, but one spoke was a half-inch longer than the other two! First I cut the long spoke and shortened it. Wasn't happy with that. Cut the spokes back out, There is a hole in the welding table that was a touch too tight to stick the hub through so it got enlarged just enough where I could stick the hub in and spin it, drawing a circle on the table. Then the outer frame was tacked to the table measuring to square it up making the sides as parallel with each other best I could. Got within a 16th. Then I dropped the spokes in and fitted them better. Hub is centered within a 16th too. 1/4" drill bits made the spacing right.

Tacked things first, cut the welds holding it on the table and put it on the tail and spun it. Looked good so tacked it back down on the table and welded it up.

Cleaned it up with a flap wheel. Clean the tail up and it will be ready for some MF red. Going to try to clean the galvanized parts and leave as is.

Will probably be helping Loree with the tree and decorations during the weekend so there may not be much shop time.

DAC

Tacked things first, cut the welds holding it on the table and put it on the tail and spun it. Looked good so tacked it back down on the table and welded it up.

Cleaned it up with a flap wheel. Clean the tail up and it will be ready for some MF red. Going to try to clean the galvanized parts and leave as is.

Will probably be helping Loree with the tree and decorations during the weekend so there may not be much shop time.

DAC

Had some time to work on the windmill today. Cleaned the galvanized parts with CLR.

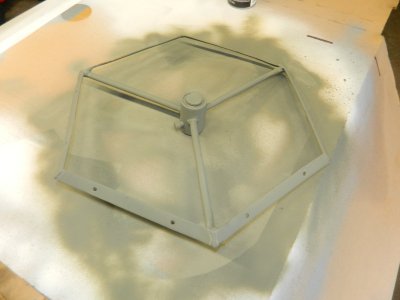

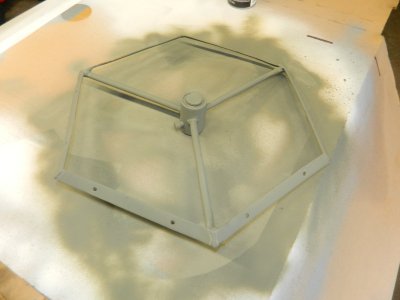

Wire wheeled the steel part of the wind vane, cleaned the bare steel parts with brake cleaner. Masked off some areas and sprayed etch primer on the areas to get paint,

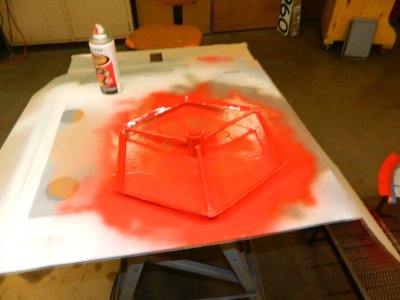

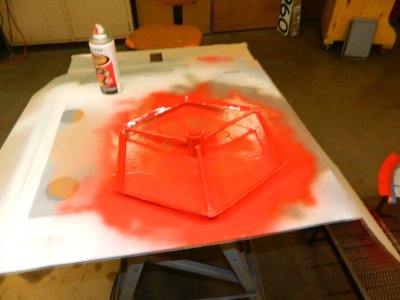

Hit the primer with a scotch brite and tack rag, then got some red paint on it.

It's still too tacky to pull the masking. Might be tomorrow.

DAC

Wire wheeled the steel part of the wind vane, cleaned the bare steel parts with brake cleaner. Masked off some areas and sprayed etch primer on the areas to get paint,

Hit the primer with a scotch brite and tack rag, then got some red paint on it.

It's still too tacky to pull the masking. Might be tomorrow.

DAC

Yes Chris, the original tower is salvageable. The lattice structure is surprisingly pretty good. The platform below the head will need quite a bit of work though. I will try to get it into the shop tomorrow to evaluate what needs to be done so wind like we are having today doesn't flatten it!Your making good headway on this.

Are you going to use the original tower?

Didn't get anything done today. Was my birthday so lunch with several cousins. Loree took the afternoon off work so we did more Christmas decorating in the house.

DAC