Yes sir. I thought I remembered it being 15,000 volts. Made a nice puff of smoke when the cows got too close to the fence. We used to take one end of those and hook to the welding table and the other end to a large well insulated screw driver. You could walk a nice arc around the table top. Can you imagine what OSHA would do today if they saw someone doing that at work.May have looked something like this, Chris?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And more junk.

- Thread starter MFDAC

- Start date

And who knows, the ones from the welding shop may be Chinese too!Probably all Chinese burrs are made in the same place.

Burning cowhair! I used to make a toy out of old transformers too. Maybe this old one may get that treatment---LOL! Probably better do it now since I mouthed off! Don't know what it's called but old sci-fi movies would have this deal where an arc chases up a couple wires in a "V". Soon as the wires would be too far apart the arc would break and start over again at the bottom. Had one in the office of my first sign shop!Yes sir. I thought I remembered it being 15,000 volts. Made a nice puff of smoke when the cows got too close to the fence. We used to take one end of those and hook to the welding table and the other end to a large well insulated screw driver. You could walk a nice arc around the table top. Can you imagine what OSHA would do today if they saw someone doing that at work.

Tinkered in the shop all afternoon. First job was to hang one more of those HF 4' LED lights over the junk steel I have saved up for projects. I had one extra light after putting fixtures under the lift. Now it is easy to see a bunch of junk that should be hauled to scrap---LOL!

Then after getting over the shock of being able to see the useless junk back in that corner, I decided to get the MF1450 off the lift and put it outside. I need to do some work on the driveway.

It didn't crank well and the battery got low quick. Put the charger on it. No start and could smell gas. Took the air filter can and element off and the element was soaked with gas! Tried one more time to crank it and oil/gas shot out of the crankcase breather tube! I never checked the oil first as I had changed the oil not long before I put it on the lift last fall! Duma$$ me never shut off the fuel. Kind of surprised me as I didn't think fuel would gravity flow through a Kohler fuel pump when not running. Not a Chinese pump. Thought those little check valves in the pump would not allow it. Checked the oil and of course it was way overfull. Drained that crap out, let it drip for awhile and put fresh oil back in it. Fired up just fine with a different spark plug. Stuck the rake in the 3 point and ran it outside. Will have to go get more 30wt to change the oil again.

That is probably a real good reason why that thing was leaking oil so bad on the lift. It was mostly gas!

Brought the GT5000 in and put it on the lift. Ran the MF12G for awhile before closing the overhead door and raising the lift to clean the mess on the floor.

Yard doesn't need mowed yet. Maybe Thursday or so. Got an appointment with the eye surgeon Thursday too, and a funeral to go to Friday, so who knows when I will mow! The 12G may get the honors this time. The cottonwoods are dropping so now the shop has plenty of cotton inside while the overhead door was open.

DAC

Having a bad back day, but still got a couple things done. Not in the shop, but in the house. Hung the neon sign and another little one Loree got somewhere in her pool table room. Been needing to do this for a long time.

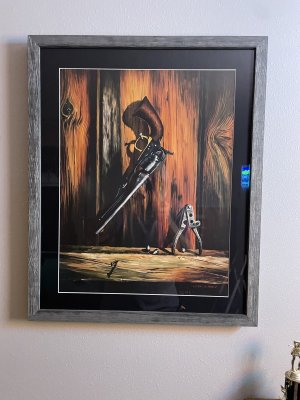

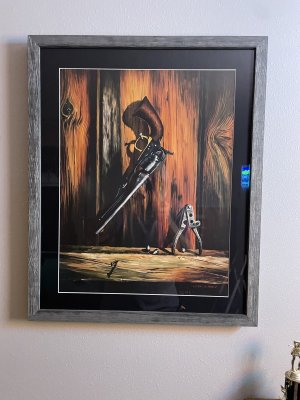

While I was at it, I hung a painting print that an old friend did.

He was the journeyman I apprenticed sign painting under 40 some years ago. We had a tight bond even though we didn't see each other a lot in later years. In 1982 we were on ladder jacks about 12-15 feet off the ground painting a billboard out in the country east of Rapid City along I-90. One of the jacks broke and we fell. He got a compound fracture of his left lower leg. I was bruised up but not hurt. I won't get into the grisly details of caring for his leg prepping him to load into the back of the pickup we had but fortunately although bleeding a lot there was no severed artery. There was a 4'x4' addition on the top of that board so I set a ladder back up and went up there with a hammer and pulled the piece off to use for a stretcher. Got him slid onto it and unloaded the pickup box. It is illegal for outdoor advertising companies to get to the sign from the interstate, but after I figured out how to load him in the truck I was going to cut the fence and head directly to the highway. His name was Jerry. He asked me to find the broken chain link and he was sure our bosses wouldn't believe it was equipment failure. I manage to find both pieces quickly. I gave him half and I kept half to show the bosses.

About that time a yellow van stopped on the shoulder of the interstate. I frantically motioned him to drive right up to the fence through the ditch. His van had no rear seats in it so we were able to pick him up on the board I had him on and slide him in the van, without cutting the fence wire in the farmer's pasture. That guy showing up could only have been devine intervention! He was the person that owned the business we were painting the sign for and he decided to take a drive out to see if we were working on it! I held the lower part of Jerry's leg and ankle the whole drive to the hospital about 30 miles away.

One of the bosses came to the hospital after I could find a phone to call and tell them of the accident and Jerry's injury, took me out to the truck and I loaded it back up and went to the shop. Jerry was right, the bosses met me soon as I got there outside and drilled me that we set the jacks up wrong. "No way the chain could break". Showed them the broken jack and they asked if I found the chain link. Still didn't believe me. I hadn't even had the time to wash the blood off my hands yet! I threw the link half in the dirt at their feet and went to my truck and went home. Pretty disgusted. They called the next day and wanted me to come back to work.

Jerry's leg ended up being an inch or two shorter than the other one after it healed up. He sure didn't need that! He was only about 4'10" tall to begin with!

Anyway, too long of a story but it was a big deal in my life at the time and major to him obviously. He died a couple years ago now and his widow gave Loree this print. She had it framed and gave it to me. Finally made myself hang it.

Ok back on track. I have had this little stud finder for a lot of years and last time I used it was probably 5 or 10 years ago---LOL!

It works great but the battery died after locating the stud I hung the neon on. Fortunately I did have one 9V battery in the box! That thing detects studs dead on and is sensitive enough a little laser shines onto the wall when centered. Very good tool! I can't hear well enough by banging on a wall anymore! Still need to come up with some genius ideas to disguise the cords some.

DAC

While I was at it, I hung a painting print that an old friend did.

He was the journeyman I apprenticed sign painting under 40 some years ago. We had a tight bond even though we didn't see each other a lot in later years. In 1982 we were on ladder jacks about 12-15 feet off the ground painting a billboard out in the country east of Rapid City along I-90. One of the jacks broke and we fell. He got a compound fracture of his left lower leg. I was bruised up but not hurt. I won't get into the grisly details of caring for his leg prepping him to load into the back of the pickup we had but fortunately although bleeding a lot there was no severed artery. There was a 4'x4' addition on the top of that board so I set a ladder back up and went up there with a hammer and pulled the piece off to use for a stretcher. Got him slid onto it and unloaded the pickup box. It is illegal for outdoor advertising companies to get to the sign from the interstate, but after I figured out how to load him in the truck I was going to cut the fence and head directly to the highway. His name was Jerry. He asked me to find the broken chain link and he was sure our bosses wouldn't believe it was equipment failure. I manage to find both pieces quickly. I gave him half and I kept half to show the bosses.

About that time a yellow van stopped on the shoulder of the interstate. I frantically motioned him to drive right up to the fence through the ditch. His van had no rear seats in it so we were able to pick him up on the board I had him on and slide him in the van, without cutting the fence wire in the farmer's pasture. That guy showing up could only have been devine intervention! He was the person that owned the business we were painting the sign for and he decided to take a drive out to see if we were working on it! I held the lower part of Jerry's leg and ankle the whole drive to the hospital about 30 miles away.

One of the bosses came to the hospital after I could find a phone to call and tell them of the accident and Jerry's injury, took me out to the truck and I loaded it back up and went to the shop. Jerry was right, the bosses met me soon as I got there outside and drilled me that we set the jacks up wrong. "No way the chain could break". Showed them the broken jack and they asked if I found the chain link. Still didn't believe me. I hadn't even had the time to wash the blood off my hands yet! I threw the link half in the dirt at their feet and went to my truck and went home. Pretty disgusted. They called the next day and wanted me to come back to work.

Jerry's leg ended up being an inch or two shorter than the other one after it healed up. He sure didn't need that! He was only about 4'10" tall to begin with!

Anyway, too long of a story but it was a big deal in my life at the time and major to him obviously. He died a couple years ago now and his widow gave Loree this print. She had it framed and gave it to me. Finally made myself hang it.

Ok back on track. I have had this little stud finder for a lot of years and last time I used it was probably 5 or 10 years ago---LOL!

It works great but the battery died after locating the stud I hung the neon on. Fortunately I did have one 9V battery in the box! That thing detects studs dead on and is sensitive enough a little laser shines onto the wall when centered. Very good tool! I can't hear well enough by banging on a wall anymore! Still need to come up with some genius ideas to disguise the cords some.

DAC

Got a couple more small tools from Temu today. Number and letter stamps and a drill adapter that I thought would be 90* but it's not. Oh well it was cheap and still might help in some situations.

Then since some cloud cover came in decided to do an outside chore that needed done. Didn't realize them clouds were full of rain---LOL! Something that should have taken me a half hour ended up being a couple of hours, not all due to rain coming and going. So much for the 20% chance that "they" said we had for today!

There were a couple of broken or rotted off fence posts on the west side of the back yard. They were tipped over where the neighbor had to dodge them for mowing. The only reason I leave that fence there is to give a rough definition of the property line.

Fired up the MF1450 and put the gravel drag on the 3 point to throw some tools on. Got to the first post, backed in and hooked a tow rope to the post and the tractor. Tractor died, wouldn't start. Checked the gas and it was empty. Could have sworn I put about half tank in it the other day after I changed the oil. You might remember I had forgotten to close the fuel shutoff and the crankcase filled with gas. First thing I thought was the fuel shutoff must leak too and the crankcase is full of gas again! Checked the oil. Just below the full line right where I had filled it to before I ran out of 30wt. Looks like another brain fart, senior moment.

About that time the rain came down. Closed the hood and headed to the shop. Got a gas can ready for when the rain stops. When it did, went out and put some in. Cranked it for a minute and the battery died. Oh well, raining again.

Went back to the shop and got the battery from the JD110 off the maintainer and grabbed some jumper cables. Rain stopped again. Carried that stuff out there and the jump got it going! Pulled the first post up and drove angle iron bed frame about 4' long into the ground on the falling side. Left the tractor running this time and the amp gauge showed a good charge. Took the gas can, battery and jumper cables back to the shop on the drag this time since it was starting to rain again. Left the tractor running and waited it out. When it quit again went back and pulled the other post up and drove the angle iron in. Didn't get wet that time! Only pic I got was the second post since the rain was playing with me.

It was hot and humid so I was sweaty. Took the tractor back to it's outside parking spot and closed the gas shutoff. It works! The engine ran for a minute or so and died. I did remember to turn the ignition switch off---LOL!

Started raining again!

DAC

Then since some cloud cover came in decided to do an outside chore that needed done. Didn't realize them clouds were full of rain---LOL! Something that should have taken me a half hour ended up being a couple of hours, not all due to rain coming and going. So much for the 20% chance that "they" said we had for today!

There were a couple of broken or rotted off fence posts on the west side of the back yard. They were tipped over where the neighbor had to dodge them for mowing. The only reason I leave that fence there is to give a rough definition of the property line.

Fired up the MF1450 and put the gravel drag on the 3 point to throw some tools on. Got to the first post, backed in and hooked a tow rope to the post and the tractor. Tractor died, wouldn't start. Checked the gas and it was empty. Could have sworn I put about half tank in it the other day after I changed the oil. You might remember I had forgotten to close the fuel shutoff and the crankcase filled with gas. First thing I thought was the fuel shutoff must leak too and the crankcase is full of gas again! Checked the oil. Just below the full line right where I had filled it to before I ran out of 30wt. Looks like another brain fart, senior moment.

About that time the rain came down. Closed the hood and headed to the shop. Got a gas can ready for when the rain stops. When it did, went out and put some in. Cranked it for a minute and the battery died. Oh well, raining again.

Went back to the shop and got the battery from the JD110 off the maintainer and grabbed some jumper cables. Rain stopped again. Carried that stuff out there and the jump got it going! Pulled the first post up and drove angle iron bed frame about 4' long into the ground on the falling side. Left the tractor running this time and the amp gauge showed a good charge. Took the gas can, battery and jumper cables back to the shop on the drag this time since it was starting to rain again. Left the tractor running and waited it out. When it quit again went back and pulled the other post up and drove the angle iron in. Didn't get wet that time! Only pic I got was the second post since the rain was playing with me.

It was hot and humid so I was sweaty. Took the tractor back to it's outside parking spot and closed the gas shutoff. It works! The engine ran for a minute or so and died. I did remember to turn the ignition switch off---LOL!

Started raining again!

DAC

I’ve got a cart ready on Temu but haven’t ordered anything yet. I have ordered several things on tictok and have been pleased. I use to have a set of those numbers and letters but some how like several things not anymore.

I laughed when you were leaving your tractor run. I do that with my CC 1050 cutting grass lately it has a strong personality when it comes to starting. My new high dollar starter spins it fine now, back when it never I changed the valve settings trying to help it spin. When I get a chance I’m going to adjust back to factory settings.

I laughed when you were leaving your tractor run. I do that with my CC 1050 cutting grass lately it has a strong personality when it comes to starting. My new high dollar starter spins it fine now, back when it never I changed the valve settings trying to help it spin. When I get a chance I’m going to adjust back to factory settings.

I need to try the stamps yet to see if they are good enough quality to last for a while! Got a bunch of keys I want to stamp. Kind of odd how tools disappear sometimes. I can't blame anyone else either. No one ever asks to borrow from me. I may order a few more items from them since this stuff got here pretty fast. Sounds like they are setting up warehouses in the US.I’ve got a cart ready on Temu but haven’t ordered anything yet. I have ordered several things on tictok and have been pleased. I use to have a set of those numbers and letters but some how like several things not anymore.

I laughed when you were leaving your tractor run. I do that with my CC 1050 cutting grass lately it has a strong personality when it comes to starting. My new high dollar starter spins it fine now, back when it never I changed the valve settings trying to help it spin. When I get a chance I’m going to adjust back to factory settings.

Left the tractor running since I had killed the battery mainly. Let it charge. I am paranoid about shutting it off while using it out in the yard since it seems the Kohler fuel pump leaks gas into the crankcase too. Might have to modify the fuel line or the hood to reach the shutoff without opening the hood constantly.

Had to go to walmart this morning. That always gets on my nerves, but there wasn't too many weirdos there today---LOL! got home and put new swivels on our American Flag out front. Ordered a set off of Amazon. Ball bearing ones. Seem to be working for now. Suppose they are Chinese too but I made sure when we got a new flag last year that it was American made at least.

Then I got the Craftsman GT5000 off the lift and did the roller bearing job on the front spindles.

Cleaned things up and assembled.

I packed "Molykote" grease into the bearings. Bought a cheap bicycle tube while I was at walmart. With all the junk I have around here, there's no old bicycle wheels to rob tubes out of. Was going to sacrifice it but the diameter was too big to fit the washers and spindle. Not sure how it could attach to the mount in the axle anyway. Probably would need one of those skinny 10 speed tubes like those bikes back in the '70's but there were none at that store. Will try it as is. Lubed all the zirks set it down and went for a test drive, just in time to get rained on again---LOL!

Like Roger had also mentioned, the surfaces may not be perfectly square with each other. Both spindle tubes have a small amount of wobble in them. I could not see any bushings in the cast iron axle tubes either. Spindle shafts look good.

It drove well and I think less effort. Probably know better after the first mow with this setup is done. Just going to try to keep those rollers clean as I can. Really don't know of a way to keep the debris out other than the inner tube idea.

DAC

I have found that the cheap $5 HF flag last the longest and look just as good as the $15--$20 flags. They are a light weight and mesh type material so part of the wind blows through them. Not near as much whip to the outside end which is what tears the regular flags up. Takes a lot less wind to make them flow nice also.

More junk hauled home this morning. Saw an ad for a ATV/Motorcycle lift on FB. $25. Somehow he still had it. 40 mile round trip but I think for that money it was worth it.

Chinese made Craftsman.

Jacked up a tractor. It lifts about 17" is all.

This handle came with it. Obviously broken off of somewhere. Haven't looked it over well enough to see where.

I figured out my balance is nowhere near good enough the stand on one foot pumping it---LOL!

Have to sign off right away as we are taking our sone to dinner for his birthday.

Did I need it? Probably not!

DAC

Chinese made Craftsman.

Jacked up a tractor. It lifts about 17" is all.

This handle came with it. Obviously broken off of somewhere. Haven't looked it over well enough to see where.

I figured out my balance is nowhere near good enough the stand on one foot pumping it---LOL!

Have to sign off right away as we are taking our sone to dinner for his birthday.

Did I need it? Probably not!

DAC

Last edited:

Handle broke off the pump side, just above pump ram. With it welded back, then you can hold it for balance. Have one similar I bought over 35 years ago. Still works fine, but very heavy and mine has no handle.

I read this on my phone this morning Daniel, but not signed in to reply. I get too mad trying to type on my phone. Thanks for your replies! Put me in the right direction on where to look!Yours must have some years on it to being it has an actual metal ID tag instead of a stupid sticker!

Valuable information, Stew, thanks! I had not taken time yet to do a search for that!Manual for your new find

I had to make a sign design (honeydoo) for my wife's church after she got home, but about the time the race started I got done with that and got to work on the new to me jack. Put it on some sawhorses and removed that bracket.

This chunk of steel belongs in that hole.

Clamped it in the vice and welded it up. It was not welded on the top or bottom from the Chinese factory, but it is now.

Sprayed some Krylon satin black on the welded areas and the spot I cleaned for the welder ground. it was dry in about 15 minutes so it got installed. The stupid sticker did not survive---LOL!

Put it on the floor and my feeble @$$ was able to jack up a tractor without falling---LOL! It will probably need some kind of lift deck built for it, but it works. It stayed under that tractor last night and did not bleed off at all.

I came up with a "brilliant" idea last night in my sleep and even remembered it today! I have an old Murray LT out behind the shop that is running fine but the deck belt will not stay on any more. I don't want to mess with it. Used the gas tank and seat on the JD110. I was going to scrap it. Spraying weeds is brutal on my back. Decided to build a bracket on each side to hold the bottle and I will drive along to spray. I can figure out a tank and seat without spending much. Maybe will get to work on that this week. Been way to windy to spray, so weeds are getting bad in the gravel. Here in western South Dakota, when the windy season subsides, the heat rolls in! Be 100F by late week "they" say.

DAC

I just use the small jugs of weed spray so don't have to pull a tank. Only have an acre, and the biggest problem is the gravel driveway. I figured some kind of jug holder on both sides so I can switch the jug to whatever side is needed. Maybe have a jug on both sides---LOL! I never buy them one at a time anyway. And yes, I'm too lazy to mix my own!

Ran tractors out and lowered the lift to put the Denali on it for an oil change. I covered the greasing adventure in Bills Battery grease gun thread.

It really hurt my feelings to use my last 6 quart case of Mobil1 from the days before the war on oil companies was started by this administration. Used to be able to get the 6 quart case for 27 bucks at Sam's Club. Add 17 bucks to that price now. We would pick one up during the frequent sales back then up until 2021. Price went crazy since. I had 3 or 4 cases in stock and now none!

Oh well the truck is good to go for a while now!

DAC

Ran tractors out and lowered the lift to put the Denali on it for an oil change. I covered the greasing adventure in Bills Battery grease gun thread.

It really hurt my feelings to use my last 6 quart case of Mobil1 from the days before the war on oil companies was started by this administration. Used to be able to get the 6 quart case for 27 bucks at Sam's Club. Add 17 bucks to that price now. We would pick one up during the frequent sales back then up until 2021. Price went crazy since. I had 3 or 4 cases in stock and now none!

Oh well the truck is good to go for a while now!

DAC

Got the crane attachment put on the MF1450 and went around back to drag the old Murray out of the weeds today.

Forgot to take the phone with me for a pic. Got pretty hot out today, so didn't mess around too much outside. Dropped it in front of the overhead door and shoved it in quick.

Put a battery in it and it cranked over fine. Pulled the hood and there is a gas tank in it with gas in it! Guess the tank I used in the JD110 was out of an old Craftsman out back. Looks like I changed the oil a couple years ago but this engine leaks Had to add a little it was right on the add line. Yeah I just used some 10-40 I had laying around. Think the leak is where the dipstick elbow where it goes into the block.

The non-ethanol gas still smelled fine so I cranked it to see if it would start. After about 10 revolutions it was running! Stuck a seat on it and tried the gears. All worked. Then I started smelling something burning and a bunch of smoke! Shut it down and looked down in front of the battery. Looks like the plastic tensioner flat pulley was seized up and the belt was melting it. More on that later.

Lifted it up with the atv jack and got the deck out from under it. Shoved the deck outside and hauled it around back.

Backed the 1450 into the shop to use the crane to lift it where I could see under it better. Log chained it to the lift and let a little pressure off the crane.

Got that pulley off measured it and ordered a new steel one.

Surprisingly, the belt still looks ok. Will try it anyway.

Removed the rest of the deck mounting hardware, put air in the tires and set it back down. Getting tired but it looks like I can make the seat from the GT5000 work. Will have to drill holes in the tilt bracket and make some sort of rear support. May be able to use the Murray spring there too. Will have to modify it.

Our daughter came into town this afternoon for business so don't know what I will get done tomorrow.

DAC

Forgot to take the phone with me for a pic. Got pretty hot out today, so didn't mess around too much outside. Dropped it in front of the overhead door and shoved it in quick.

Put a battery in it and it cranked over fine. Pulled the hood and there is a gas tank in it with gas in it! Guess the tank I used in the JD110 was out of an old Craftsman out back. Looks like I changed the oil a couple years ago but this engine leaks Had to add a little it was right on the add line. Yeah I just used some 10-40 I had laying around. Think the leak is where the dipstick elbow where it goes into the block.

The non-ethanol gas still smelled fine so I cranked it to see if it would start. After about 10 revolutions it was running! Stuck a seat on it and tried the gears. All worked. Then I started smelling something burning and a bunch of smoke! Shut it down and looked down in front of the battery. Looks like the plastic tensioner flat pulley was seized up and the belt was melting it. More on that later.

Lifted it up with the atv jack and got the deck out from under it. Shoved the deck outside and hauled it around back.

Backed the 1450 into the shop to use the crane to lift it where I could see under it better. Log chained it to the lift and let a little pressure off the crane.

Got that pulley off measured it and ordered a new steel one.

Surprisingly, the belt still looks ok. Will try it anyway.

Removed the rest of the deck mounting hardware, put air in the tires and set it back down. Getting tired but it looks like I can make the seat from the GT5000 work. Will have to drill holes in the tilt bracket and make some sort of rear support. May be able to use the Murray spring there too. Will have to modify it.

Our daughter came into town this afternoon for business so don't know what I will get done tomorrow.

DAC

Thanks Jim. I didn't put the front weights on it and when I went to yank the junk tractor out I did wheelies---LOL! Had the boom up a ways. No problem getting it free from the weeds when I lowered it down all the way.Your boom lift attachment is working out good.

Had stuff going with our daughter yesterday evening, but I did get a junk seat mounted on the junk LT. Today I was able to weld some more junk (old shelf bracket) together to build a hanger for the weed killer bottles. Held it in place with a self-drilling screw to mock it up. Got it bent around where it needed to be, and tack welded it on the tractor.

Finished welds on the table and scuffed it with a scotchbrite. Took it outside and sprayed it satin black. In the near 100* temps, it still felt sticky when it should have been dry! Brought the bracket in and it felt dry when it cooled off---LOL! Used 1/4" bolts for final assembly.

Got that done and the son texted me he bought low beam headlight bulbs for his 2011 Traverse. I had told him we would do it here rather than him taking it somewhere. Ran the MF1450 and the 12G out and pushed the Murray out. Pulley isn't here yet.

That turned into a pain since dumb old dad reached into the inner fender too far and pulled out the high beam. Won't go into details but that thing wasn't designed for the owner to work on. Sucked putting that back together but the low beams weren't too bad.

Going to the races tomorrow night. An old friend is in town that I lettered a lot of cars for back in the 80's and 90's. Will meet up with him there.

DAC

Might have to make up with a sticker like that Jim---LOL!Nice rig Doug. I think the old Murray needs some “Weed Eater” graphics. Lol

That pulley came in today. It was supposed to come with bushings for various size shafts but none with it. Bearing I.D. measures 11/16" (didn't get the calipers out). Shaft is 1/2" will have to make something to adapt it.

DAC