Thanks for more input everyone! Last night trying to go to sleep I decided to just cut that seemingly useless spacer off the hydro pump input shaft when I got home from work. I stuck to my thoughts and when I got home this evening, dug out the old dremel and cutoff wheels. Managed to split it a couple times and removing it made enough room to get the coupler off.

Now more news I didn't want to see. The coupler only had about 3/4" of bite on the engine side and 1-1/4" on the hydro pump side. Lots of wear on both shafts but the engine side is rounded off.

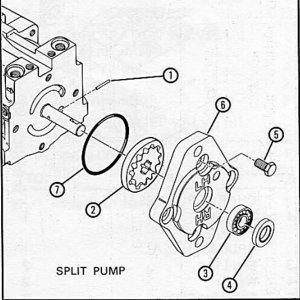

It will be much easier to pull the seal but still think of a way to do it without potentially damaging something inside the pump. I better look up a hydro parts breakdown and see what kind of a mess I may get myself into if I pull the front plate off.

I appreciate you folks following along on this adventure!

DAC

Now more news I didn't want to see. The coupler only had about 3/4" of bite on the engine side and 1-1/4" on the hydro pump side. Lots of wear on both shafts but the engine side is rounded off.

It will be much easier to pull the seal but still think of a way to do it without potentially damaging something inside the pump. I better look up a hydro parts breakdown and see what kind of a mess I may get myself into if I pull the front plate off.

I appreciate you folks following along on this adventure!

DAC

Last edited: