A long and tedious upgrade for sure and true craftsmanship. My question is: now that this weak link in the chain is fixed, will the front axle or spindles be the next weak link? Don't know if you had it already but maybe some rear counterweight would help.

Mike

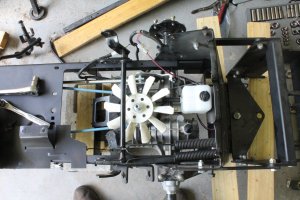

Thank you. The spindles issue is going to be another problem to address in the future, but are actually strong enough for the job in the short run. They are 3/4 inch same or almost identical to the JDX570 and the steering plate is also used on the JD. The cast iron axle is strong enough too. Here is what I don't like about it;

1) The 5/8" drag links are not adjustable (they need to be able to adjust), so the extreme toe in that they have is what you get. (I am working on a plan here too with 4x4 stuff).

2) The wheels have sleeves for bearings, I want ball bearings that can take true axle loads like trailers, horizontal and vertical load.

3) The spindle pivots at the axle conection or where they rotate, are also sleeves for bearings.

4) The axle support plates have a sleeve too, yep, I want ball bearings.

5) The steering shaft at the top should have ball bearings and a solid mount, it's very sloppy as it is now. So far the perfectionist is starting to come out

6) The factory tires are two ply, fine for cutting grass, but they need the weight capability of four ply tires at least, and the extra wall support.

I have replaced mine with four ply lugs so that they actually turn (sand tends to give way to easily and allows the front to slip forward frequently). Also another thought for someone thinking about this, if you are on a grade sideways with 200lb in the bucket at axle height, the extra wall support is good insurance for a firm footing.

The front tires are now capable of handling more weight than will ever be on the front (an extra 200lbs over the 2 ply each tire) and the support is so good that I think more of the bucket actuator force is now going to the load and not being absorbed by the squishy weak tires that came with it, does this ring true for anyone out there? (side note, a suspension on a tractor seems like a very bad idea).

On the last comment, YES YES YES, I have learned that weight equals traction! I have the rear uni sleeve from Johnny Buckets and the JD suitcase weight bracket with 4 weights. I only seem to need the weight of four when I'm working dry sand, otherwise 2 are fine (bucket use) and I think if you have actual dirt you might be fine with wheel weight and tires filled (what has been referred to as free weight)?

I observe letting the job dictate when and how much weight should be used because according to a conversation I had with Tuff Torq (so far another company that can be honest and keep their word!) the lugs and weights are fine, the K66 is built for it.......The catch.......when you use these accessories then the tractor is no longer a grass cutter and it needs to be maintained like a transaxle should. The no maintenance transaxle claimed by Husqvarna is only true if it is used for flat grass cutting only (and they are still counting on the customer to buy a new tractor before the 200 hrs anyway, I wonder why?). Husqvarna has failed to mention this, must have slipped their lawyers minds or something, huh! Tuff Torq also said, The more weight you use the sooner the time between oil changes! Tuff Torque has a general maintenance schedule on their web site that says;

first 50 hrs and every 200 hrs after. That's just for general use (grass cutters too!) If you use the weights and accessories then it is recommended that you change the oil as often as your engine oil, 25 to 50 hrs or per season. The oil is listed as either theirs or a quality 5w-50 synthetic (10w-50 synthetic is fine too but the higher weights are for heat and load). The oil also needs to be the type that is rated for a "wet clutch" such as dirt bikes and ATV's, the reason I was given is because of the "wet brake" internally. (yep, that's something I want to change too).