Had to rebuild a bird feeder for the cook this morning. Bottom rusted out. Thin metal painter copper to make it look kind of brassy in the store I guess. After a good cleaning used an empty cat food can up side down under to bottom, hot glued in place, drilled hole in the center for the rod to run from the top through the bottom to hold it all together. Think it will work if the coon stay off it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you currently working on??

- Thread starter backwoods

- Start date

The snow is all gone and my mind turns to boats. Last fall I picked up a 26 footer for free. The catch was I had to haul it out of the Dartmouth Yacht Club which meant I had to get my hands on a trailer. I picked up a 16' flatbed with a rotted deck and went to work ripping the deck off, painting, wiring lights and attaching four removable support posts. To save time and money I robbed the screw jacks off my bigger boat but had to jack her a foot in the air to get the screws and pads out. They did the trick on the new trailer, but now I want to get my big boat ready to sell and had to get the screws out from under the newer boat and back under her before I attempted moving her out to start cleaning her up. I also had to fix a wheel that I rolled the tired off the rim a couple years ago when I parked it. Jacking 4000lb and 6500lb boats by yourself can be tricky but with planning it went off without a hitch. No wait...I used a hitch.

Busy day.

Busy day.

Attachments

-

20200309_130924.jpg345.9 KB · Views: 12

20200309_130924.jpg345.9 KB · Views: 12 -

20200309_130929.jpg250.4 KB · Views: 11

20200309_130929.jpg250.4 KB · Views: 11 -

20200309_130938.jpg183.5 KB · Views: 9

20200309_130938.jpg183.5 KB · Views: 9 -

20200309_130944.jpg213.5 KB · Views: 9

20200309_130944.jpg213.5 KB · Views: 9 -

20200309_131631.jpg308.9 KB · Views: 9

20200309_131631.jpg308.9 KB · Views: 9 -

20200309_131635.jpg231.4 KB · Views: 9

20200309_131635.jpg231.4 KB · Views: 9 -

20200309_131643.jpg209.4 KB · Views: 9

20200309_131643.jpg209.4 KB · Views: 9 -

20200309_131804.jpg292.3 KB · Views: 9

20200309_131804.jpg292.3 KB · Views: 9 -

20200309_131808.jpg430.1 KB · Views: 9

20200309_131808.jpg430.1 KB · Views: 9 -

20200309_131817.jpg194.3 KB · Views: 9

20200309_131817.jpg194.3 KB · Views: 9

And...

Attachments

-

20200309_131917.jpg147.1 KB · Views: 6

20200309_131917.jpg147.1 KB · Views: 6 -

20200309_134015.jpg201 KB · Views: 5

20200309_134015.jpg201 KB · Views: 5 -

20200309_134020.jpg256.3 KB · Views: 5

20200309_134020.jpg256.3 KB · Views: 5 -

20200309_134023.jpg258.1 KB · Views: 5

20200309_134023.jpg258.1 KB · Views: 5 -

20200309_134025.jpg136.4 KB · Views: 5

20200309_134025.jpg136.4 KB · Views: 5 -

20200309_134028.jpg87.3 KB · Views: 5

20200309_134028.jpg87.3 KB · Views: 5 -

20200309_134050.jpg216.5 KB · Views: 5

20200309_134050.jpg216.5 KB · Views: 5 -

20200309_134841.jpg224.5 KB · Views: 5

20200309_134841.jpg224.5 KB · Views: 5 -

20200309_134854.jpg208.6 KB · Views: 5

20200309_134854.jpg208.6 KB · Views: 5 -

20200309_134902.jpg238.6 KB · Views: 5

20200309_134902.jpg238.6 KB · Views: 5

Then...

Attachments

-

20200309_134917.jpg226.5 KB · Views: 5

20200309_134917.jpg226.5 KB · Views: 5 -

20200309_151107.jpg243.8 KB · Views: 5

20200309_151107.jpg243.8 KB · Views: 5 -

20200309_151112.jpg313 KB · Views: 3

20200309_151112.jpg313 KB · Views: 3 -

20200309_151128.jpg242.1 KB · Views: 3

20200309_151128.jpg242.1 KB · Views: 3 -

20200309_151222.jpg165.5 KB · Views: 3

20200309_151222.jpg165.5 KB · Views: 3 -

20200309_151246.jpg133.9 KB · Views: 3

20200309_151246.jpg133.9 KB · Views: 3 -

20200309_151926.jpg127.7 KB · Views: 3

20200309_151926.jpg127.7 KB · Views: 3 -

20200309_152828.jpg328.6 KB · Views: 6

20200309_152828.jpg328.6 KB · Views: 6 -

20200309_162239.jpg240.4 KB · Views: 6

20200309_162239.jpg240.4 KB · Views: 6

Started a simple little job for the MF8E today. It has a 42" blade from a Cub Cadet on it and the litttle round skids have always been hard on a gravel driveway. I'm taking a piece of 1-1/2" pipe and going to weld tabs on it to bolt into the skid holes. I did that idea 20 or so years ago, building a "scarifier" in the same manner. I'm not sure if that is the right term. I used it 2 or 3 times to break open the hard-packed dirt surface on the go-kart track I used to host races on. It worked fine but I had to quit the racing as liability worries outweighed the fun. Whatever steel I dug out of my scrap to make tabs with, cut fine with a cut off wheel but sure wont drill! It isn't stainless either. Killed several drill bits trying to work up to a half inch hole! I'll dig in the scrap at work tomorrow and see if there is any 1/4" flat stock scraps 1-1/2" wide. Only need about 6"!

Only got this far. Cut the pipe and have it against the scarifier so I can get the hole right to fit the blade.

DAC

Only got this far. Cut the pipe and have it against the scarifier so I can get the hole right to fit the blade.

DAC

View attachment 23366

This bike is about done. Just need a few more small pieces.

View attachment 23367

This one was 10 years ago. But it was ridden quite a bit. About time for it to get a refresh. I did fix it up and get it running today. Me and the kids ran a whole tank of gas through it.

Very, very cool Aaron! Any action pictures?

DAC

Very, very cool Aaron! Any action pictures?

DAC

Didn't take any. I'll have to get some. The red bike will wheelie with me on it. It'll climb like a mule too. HM80 with a CVT on it. 21" tires. I wish they still made stuff like this. Super Bronc VT8 made in the 70s.

The goldish one is a Heathkit Hilltopper. 18" tires. H50 Tecumseh and a CVT. They are cruisers, but will tackle trails pretty well, doesn't float around quite as well as the big tired super bronc.

Bad thing about restoring these bikes is the parts are pretty darn rare, and when you do find them they are expensive. Both of those bikes have NOS OEM fuel tanks on them. I paid nearly 200 each for them. But the build isn't complete without the proper fuel tank..

Heald super bronc Heathkit hilltopper Gas Tank | eBay Here is a ok condition used one. 200 bucks right now.

Last edited:

Be working on the MF 1010 and the corn planter. Getting them mated up and ready for spring.

Also did some reprogramming of the Arduino based planter monitor.

That's a real nice setup Ducky!!! You have a sweet corn market garden? Roadside stand?

That setup would be f'ing awesome for that!

You will love the wireless. When loading tractors side by side you need to be able to steer and run the winch.

Hardest iron I ever ran into was the angle iron used on the old AC round "cigar roller" hay balers. Go real slow and used lots of cutting oil.Started a simple little job for the MF8E today. It has a 42" blade from a Cub Cadet on it and the litttle round skids have always been hard on a gravel driveway. I'm taking a piece of 1-1/2" pipe and going to weld tabs on it to bolt into the skid holes. I did that idea 20 or so years ago, building a "scarifier" in the same manner. I'm not sure if that is the right term. I used it 2 or 3 times to break open the hard-packed dirt surface on the go-kart track I used to host races on. It worked fine but I had to quit the racing as liability worries outweighed the fun. Whatever steel I dug out of my scrap to make tabs with, cut fine with a cut off wheel but sure wont drill! It isn't stainless either. Killed several drill bits trying to work up to a half inch hole! I'll dig in the scrap at work tomorrow and see if there is any 1/4" flat stock scraps 1-1/2" wide. Only need about 6"!

Only got this far. Cut the pipe and have it against the scarifier so I can get the hole right to fit the blade.

DAC

View attachment 23296

Trailer isn't wide enough for side-by-side loading. I'd need over 8 foot wide for mine. Main thing is dragging 'dead' tractors on for fixing! I can get them off at the house easily. Just on at the customer/point of purchase.You will love the wireless. When loading tractors side by side you need to be able to steer and run the winch.

Hardest iron I ever ran into was the angle iron used on the old AC round "cigar roller" hay balers. Go real slow and used lots of cutting oil.

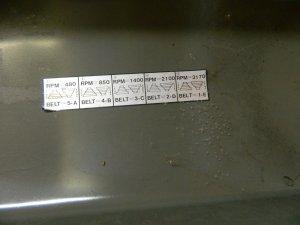

I took the pieces I tried to drill to work and showed them to the machinist. He said he would finish drilling them during lunch. He got them drilled but said that "was the hardest damm steel I've ever had to drill!" He ended up using the milling machine to finish the holes at I think he said 42 rpm. I was using lots of cutting oil and had my drill press on it's slowest speed, 480 rpm. We did have some scrap at work but he was curious why I was having a hard time drilling that stuff. I'll use them now!

DAC

Thanks, Roger! I bet they hold up well too! There's a sticker in the belt cover of my drill press with the pulley/belt/speed diagram. Looks like I better clean spiders out of there!Don't know what my drill press turns right off but the 4 step pulleys are set as slow as they will go. Glad you go them holes punched and are back in business again. Bet those holes don't get wallowed out.

I got the skid welded together this afternoon and fitted. I need to build a couple spacers to get the level where it needs to be. It just bolts into the round skid mount holes. 1/2" nc.

Welded up the holes in a couple of washers to cap the ends of the pipe so it won't fill up with gravel. Mounting tabs are in the picture too.

Capped the ends.

Bolted the tabs to the scarifier that already fits the blade and welded them to the pipe.

Fitted it on the Cub Cadet blade that's on the MF8E.

Stopped there for now. Hopefully it might save the driveway from gravel gouging.

DAC