Yea Mike, I have a 2001 Durango and it just keeps going. We bought for my daughter 3 yrs ago when she turned 16 so she could get her license, she's only driven it once and still no license. I think it maybe starting to have tranny issues, every once in a while it slips into gear after it sits for a while.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you currently working on??

- Thread starter backwoods

- Start date

Worked on the Cub 1650 some more, freed up some linkage, removed the old isolation motor mounts, repaired the drive shaft, trimed down a Bolens hydro fan to clear in the cub. Drew up what I needed for the coupler from the Briggs to the drive shaft. Don't have the right material on hand so will let my fried at the welding shop build it. The slime I put in the rear tire yesterday worked as usual and stopped the tread leak. Going to put a piece of plywood under the frame with a jack and set the Briggs on that just to see what I have or lack for clearances, etc. Plan is to set the engine in on a plate and fire it up connected to the hydro so see if the hydro is OK, etc. Have two extra rear ends sitting on a pallet just in case.

Last edited:

mine has the 5.9 (old "360 cu. in") engine, currently has 258K miles, rust free which is rare around here. Bought 6-7 years ago with 214K on it, like a month after it arrived from Louisiana. not interested in anything with a 4.7L, no experience with those at all....

I bought it, knowing at the time that I'd probably be putting an engine into it, because it was so clean, but it had highest miles of any vehicle I have ever had did, at start of me buying it/owning it.

Had been a very good dependable vehicle for us, until a computer issue that gave me a chronic #6 misfire on the orig engine. I actually got more out of it before the "inevitable" happened than I thought I might.

Issues with the misfire started around 252K miles.

Did a compression test on that bank (numbered just like a Chevy, odds on driver side, evens on pass side) 150 straight across.

Complete tuneup with the "better grade" of cap rotor wires plugs (it was due anyway, almost 40K since I did the initial one when I bought it) No change. At first it would show check engine lite but couldn't tell it had an issue by the way it ran. That changed.

swapped injectors between cylinders. Still misfire on #6. Took injectors in to a Bosch fuel injection place. flushed, tested, rebuilt. All good, "just needed a good cleaning"

sent computer into computer rebuild place I found online, they went thru it and found issue. Got back, issue gone. but came back.

in the meantime oil pressure started going goofy, but typical of high mileage. Time for the engine swap.

I went to CL and found another, took that one apart and sent to machine shop for anything it needed. Bored, hot tanked, crank polished std (this engine didn't need crank ground) I have cam bearing tool, put those in myself.

Also rebuilt trans "just because" I didn't know its history and "because I can". also new fuel pump along with new engine, again "just because".

Assembled short block, all clearances were spot on, put original cam back in but new lifters and all new pistons, rings, T chain, oil pump,gaskets, etc.

Bought BRAND SPANKING NEW "EngineQuest" fully assembled heads. 3rd set of these heads that I have used on various projects, 1st 2 sets were great. Original Mopar Magnum heads have tendency to crack, so I decided to splurge for the new heads.

got it assembled and installed, started right up without even a lifter tick, as I ran the oil pump with a 3/8" drill while on the stand to verify pressure and prelube everything. Ran @2000 RPM that 1st nite for about 45 min/maybe an hour. 2nd nite. stared and ran, monitored scanner and gauges, warmed up, so far so good.... 3rd nite with new engine.... test drive time. I never was able to achieve 50 MPH.. Huh???? Check engine light and codes galore, stalled 3 miles from home and couldn't get it going, exhaust was glowing like red neon, melted down brand new cat....

get it home, got it going next day, but not well.... found out injector on time at idle was 5-6x as long as normal for idling engine. Different wiring harness... no help. different computer.... no help. added redundant grounds.... no help. sent both original and replacement computer back in, they found issue with original one, said they had canned orig tech that worked on that one the 1st time, theyd had issues with this person. They both redid that one and programmed 2nd computer for my VIN at no charge. Cant complain about that.

Meanwhile, I decided that 2-1/2-3 hours was enough run time on break in oil. When I went to drop that oil, I found a slurry of bearing material. At that point I threw up my arms and parked it. Never had that happen before. figure excess fuel "washed out" cylinders and new rings, like when a float would stick on a carbd engine in older days. this was Nov '16.

fast forward to last month. found another 360 on CL, lower miles than the 1st, 125K less than whats on the body. Figured to just drop it in, but "well Id better replace gaskets and freeze plugs while access is better than in chassis". Head off issues, sort of thinking. OK, I'm pulling the heads for new gaskets (I have a stack of em ere, just because I found a "deal" on them) OK the "might as wells" kick in. I want my new heads on this shortblock, have this engine apart anyways..... and when I went to pull new heads off of the 1st overhauled engine that's when I discovered the problem.... never dealt with that before.... so I sent those brand new heads thru the machine shop and they found a lot wrong with them....

so I started googling and it seems that Enginequest went thru a bad spell around the same time that I bought my set of heads.... same problem as I experienced.... would have been warranty if I had gotten right to it (1 year warranty, its been 3) but I don't think they would have done anything for the collateral damage to the short block, so I'd be out that money anyways..... too late to see what they would have done now.....

in the meantime I pulled the pass side head off of the original -original engine, crosshatch still visible in cylinders even after all those miles, cant see anything wrong with original head.... my son wants that engine to rebuild for one of his "projects"

I bought it, knowing at the time that I'd probably be putting an engine into it, because it was so clean, but it had highest miles of any vehicle I have ever had did, at start of me buying it/owning it.

Had been a very good dependable vehicle for us, until a computer issue that gave me a chronic #6 misfire on the orig engine. I actually got more out of it before the "inevitable" happened than I thought I might.

Issues with the misfire started around 252K miles.

Did a compression test on that bank (numbered just like a Chevy, odds on driver side, evens on pass side) 150 straight across.

Complete tuneup with the "better grade" of cap rotor wires plugs (it was due anyway, almost 40K since I did the initial one when I bought it) No change. At first it would show check engine lite but couldn't tell it had an issue by the way it ran. That changed.

swapped injectors between cylinders. Still misfire on #6. Took injectors in to a Bosch fuel injection place. flushed, tested, rebuilt. All good, "just needed a good cleaning"

sent computer into computer rebuild place I found online, they went thru it and found issue. Got back, issue gone. but came back.

in the meantime oil pressure started going goofy, but typical of high mileage. Time for the engine swap.

I went to CL and found another, took that one apart and sent to machine shop for anything it needed. Bored, hot tanked, crank polished std (this engine didn't need crank ground) I have cam bearing tool, put those in myself.

Also rebuilt trans "just because" I didn't know its history and "because I can". also new fuel pump along with new engine, again "just because".

Assembled short block, all clearances were spot on, put original cam back in but new lifters and all new pistons, rings, T chain, oil pump,gaskets, etc.

Bought BRAND SPANKING NEW "EngineQuest" fully assembled heads. 3rd set of these heads that I have used on various projects, 1st 2 sets were great. Original Mopar Magnum heads have tendency to crack, so I decided to splurge for the new heads.

got it assembled and installed, started right up without even a lifter tick, as I ran the oil pump with a 3/8" drill while on the stand to verify pressure and prelube everything. Ran @2000 RPM that 1st nite for about 45 min/maybe an hour. 2nd nite. stared and ran, monitored scanner and gauges, warmed up, so far so good.... 3rd nite with new engine.... test drive time. I never was able to achieve 50 MPH.. Huh???? Check engine light and codes galore, stalled 3 miles from home and couldn't get it going, exhaust was glowing like red neon, melted down brand new cat....

get it home, got it going next day, but not well.... found out injector on time at idle was 5-6x as long as normal for idling engine. Different wiring harness... no help. different computer.... no help. added redundant grounds.... no help. sent both original and replacement computer back in, they found issue with original one, said they had canned orig tech that worked on that one the 1st time, theyd had issues with this person. They both redid that one and programmed 2nd computer for my VIN at no charge. Cant complain about that.

Meanwhile, I decided that 2-1/2-3 hours was enough run time on break in oil. When I went to drop that oil, I found a slurry of bearing material. At that point I threw up my arms and parked it. Never had that happen before. figure excess fuel "washed out" cylinders and new rings, like when a float would stick on a carbd engine in older days. this was Nov '16.

fast forward to last month. found another 360 on CL, lower miles than the 1st, 125K less than whats on the body. Figured to just drop it in, but "well Id better replace gaskets and freeze plugs while access is better than in chassis". Head off issues, sort of thinking. OK, I'm pulling the heads for new gaskets (I have a stack of em ere, just because I found a "deal" on them) OK the "might as wells" kick in. I want my new heads on this shortblock, have this engine apart anyways..... and when I went to pull new heads off of the 1st overhauled engine that's when I discovered the problem.... never dealt with that before.... so I sent those brand new heads thru the machine shop and they found a lot wrong with them....

so I started googling and it seems that Enginequest went thru a bad spell around the same time that I bought my set of heads.... same problem as I experienced.... would have been warranty if I had gotten right to it (1 year warranty, its been 3) but I don't think they would have done anything for the collateral damage to the short block, so I'd be out that money anyways..... too late to see what they would have done now.....

in the meantime I pulled the pass side head off of the original -original engine, crosshatch still visible in cylinders even after all those miles, cant see anything wrong with original head.... my son wants that engine to rebuild for one of his "projects"

Fitting the Vanguard in the cub to see what I need to mount it on, how high I need to raise it for clearance, etc. Sitting on 7/8" strips of wood in the photos. I need a bit more height for comfortable clearance of the flywheel shroud and the starter. It clears now but is real close. I don't think the original Cub gas tank will work so will come up with something else on that. Haven't checked the clutch alignment yet either.

Remotoring the 1650 IH Cub with a 16hp B&S Vanguard continues.

Picked up some material from the welding shop scrap pile yesterday. He may be a little high on his work but I have yet to be charged for items I get from his scrap pile. Got some 1/4 X 1" flat and some 1" square tubing. Tacked two pieces of the 1/4" flat onto the bottom of the tractor frame where the engine will sit. Cut 2 12-1/4" pieces of the square tubing to mount cross ways for the engine to sit on. Got the holes drilled and the bolts tacked to the bottom of the front tube as there will be no access to the bolt heads right over the front axle. That part is done. Have to wait for the drive shaft coupler, get that hooked up and the tractor frame marked where the square tubes will sit so I can weld them to the rise strip. Might get by with using the original oil filter, but it will be close.

Picked up some material from the welding shop scrap pile yesterday. He may be a little high on his work but I have yet to be charged for items I get from his scrap pile. Got some 1/4 X 1" flat and some 1" square tubing. Tacked two pieces of the 1/4" flat onto the bottom of the tractor frame where the engine will sit. Cut 2 12-1/4" pieces of the square tubing to mount cross ways for the engine to sit on. Got the holes drilled and the bolts tacked to the bottom of the front tube as there will be no access to the bolt heads right over the front axle. That part is done. Have to wait for the drive shaft coupler, get that hooked up and the tractor frame marked where the square tubes will sit so I can weld them to the rise strip. Might get by with using the original oil filter, but it will be close.

Last edited:

Still working on the Craftsman Pro Estate find. Still waiting on the deck at the metal fabricaters, Will be ordering 1/2 the parts needed tonight. pressure washed more parts on prep for sanding and paint. On hold due to BBQ and rain right now. Still need to locate a service manual for the trans-axle.

Have some Sears 50" deck parts if anyone needs them.

Have some Sears 50" deck parts if anyone needs them.

Attachments

I spent about 4-5 hours putting the mower deck back on the Ingersoll. No that wasn't a misprint. I've always thought the mower was a pain, but usually I would pull and jerk and raise and lower it and finally it would jump in place. This time there was no way it was going to cooperate. I went on the CaseIngersoll Forum and asked for instruction and what they told me was how I was trying to do it. You would have to know Case to understand what I finally had to do, but it wasn't normal.

Guys!!! Wheel Horse are soooo easy to mount the accessories. Everyone should have one.

Guys!!! Wheel Horse are soooo easy to mount the accessories. Everyone should have one.

Kind of sounds like the Bolens Qt series decks. Heavy as all get out to handle and MUST be on level ground. Follow the instructions and not to bad. Hardest part is to get it lined up right side to side and square with the tractor. Seems like you move it one way and the other goes way off. The Cub Cadet quick attach are real simple to put on and off also.

When I bought the ranger the radio in it never powered up and the hour meter did not work. Decided this morning to get the hour meter working. Started looking for a schematic and everything that was to be for an 04 Polaris Ranger 500 was for a Polaris, 4 X 4. Started tracing wires where I could not get at the and inside a big plastic loom. Found a blown fuse, replaced that and the radio now power up. Found a wire that was hot only when the key was on so tapped into that and run another power wire to the hour meter and got it working. Headed for the garden and picked about 3 dozen or more BIG yellow cucs and a couple dozen of nice size green cucs. Big ones got cut up for the goats and Mr. Rooster. Mrs took some for cucs and onions and the rest went to the neighbor. While I was at the garden I checked the Rattlesnake Watermelon. Have about a dozxen nice sized melons. The pig tail on one is about dry. Maturity is 90 to 100 days so about the 20th of September the 100 d ays will be up and am sure will have some ready before then. Muskmelon are doing good but green yet so will be late also. Tomorrow I have to make a bunch of cedar square risers to put under the muckmelon to keep them from rotting with all the rain. Ground is wet under the leaves.

Another 8 risers made for the Muskmelon to go under them this morning. Picked up the engine to drive shaft adapter from the welding shop yesterday evening. Will see if I can get things together enough for a hydro & rear end test this morning. Will have to mow this after noon or possibly later this morning if it drys off.

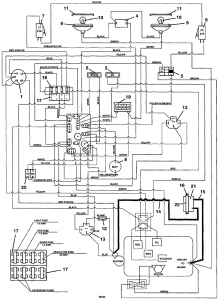

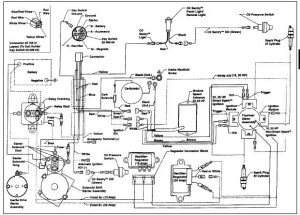

I got dragged into helping a friend make heads or tails out of a Grasshopper 725k. It has a CH25 Kohler in it, I have never worked on one of those engines yet. The wiring is a mess, the worst I have ever seen, the PO added a ton of redundancy, and about 3 tons of butt connectors and scotchloks to the mix.

The 1st thing I need to know is that I have heard that some of those engines had an ignition system called SAM on them that is a pain to deal with, how do I know if this engine has it and can someone enlighten me on what it means and how it is supposed to work?

There is a module of some kind bolted to the base of the carb perpendicular to the choke and throttle shafts. What would this be/ it has a single red wire coming from it with a spade terminal on it. Will this engine run without it and where is that red wire supposed to go? It looks other wise like any other magneto electronic ignition only with separate coils for each cylinder, with a simple spade sticking out of each coil for a kill wire. It had that oil sentry on it at one point but that is MIA any more. And we don't care about adding it back in.

It also wasn't charging the battery but the middle wire to the regulator was dangling in the wind. I can figure that part out along the way, hopefully the stator and regulator are ok

The 1st thing I need to know is that I have heard that some of those engines had an ignition system called SAM on them that is a pain to deal with, how do I know if this engine has it and can someone enlighten me on what it means and how it is supposed to work?

There is a module of some kind bolted to the base of the carb perpendicular to the choke and throttle shafts. What would this be/ it has a single red wire coming from it with a spade terminal on it. Will this engine run without it and where is that red wire supposed to go? It looks other wise like any other magneto electronic ignition only with separate coils for each cylinder, with a simple spade sticking out of each coil for a kill wire. It had that oil sentry on it at one point but that is MIA any more. And we don't care about adding it back in.

It also wasn't charging the battery but the middle wire to the regulator was dangling in the wind. I can figure that part out along the way, hopefully the stator and regulator are ok

got engine numbers.... CH25S 65862 ser 2725801897

I guess this red wire comes from the "anti backfire solenoid...."

the wiring didn't look like that when we started and won't when we finish, will be miles of wire (including PO add ons" in "file 13" I think the root issue was with that circuit board and the PO did tons of bypasses that either didn't work or corroded due to open unsealed butt connectors and Scotchloks… I hate those things with a passion. We will handle the wiring 1st and then will get to figuring out the engine, and whether it has any issues or whether it is all in the rig job with the wiring.....

the old coils had 1 spade terminal (or the kill/ground wire) the new ones that Bill bought both have 2 spades.... wrong coils? IDK that this motor even needs coils yet.... those may be returned even if they are the right (superseded?) coils for the engine.

Id like to start the engine without being wired up to the machine to separate the possible engine issues from tractor/chassis issues, before I get too much deeper into this thing. from what the current owner says the place he got the coils from this is an "older" engine as the Command series goes.... I couldn't confirm or deny that.... hopefully that means it is more "basic" and doesn't have any crazy crap "extras" on it to compound things....

I guess this red wire comes from the "anti backfire solenoid...."

the wiring didn't look like that when we started and won't when we finish, will be miles of wire (including PO add ons" in "file 13" I think the root issue was with that circuit board and the PO did tons of bypasses that either didn't work or corroded due to open unsealed butt connectors and Scotchloks… I hate those things with a passion. We will handle the wiring 1st and then will get to figuring out the engine, and whether it has any issues or whether it is all in the rig job with the wiring.....

the old coils had 1 spade terminal (or the kill/ground wire) the new ones that Bill bought both have 2 spades.... wrong coils? IDK that this motor even needs coils yet.... those may be returned even if they are the right (superseded?) coils for the engine.

Id like to start the engine without being wired up to the machine to separate the possible engine issues from tractor/chassis issues, before I get too much deeper into this thing. from what the current owner says the place he got the coils from this is an "older" engine as the Command series goes.... I couldn't confirm or deny that.... hopefully that means it is more "basic" and doesn't have any crazy crap "extras" on it to compound things....

Have a Bolens G11 with 11hp Horizontal shaft Briggs. Has a good clutch on it and thought I would swipe the clutch off it to put on the

Vanguard going in the Cub. Had to remove the front cross member with the hood to get at the clutch. Tried removing the bolt going into the end of the crank & all it did was spin ? ? Removed the four nuts that hold the plate over the clutch to the engine. Won't come off as the engine mounts are in the way. Have to pull the engine to remove the clutch. The engine starts and runs good, valves are good and have been lapped but it smoke like no tomorrow. Needs rings. Don't think the tractor is worth anything with a smoking engine and not attachments. Steering wheel was missing and don't have the right one. I think it is going to be a parts tractor, starting with a torch on the front motor mounts so I can get the clutch off, then remove the choke and throttle cables, amp gauge and key switch. Rest can wait for another day. Might throw a set of rings in the engine this winter just to have another horizontal shaft on hand. Have HH160 that is good, an 8 hp Wisconsin that needs rebuilt, and another Wisconsin 8 or 10 hp. status unknown.

The engine starts and runs good, valves are good and have been lapped but it smoke like no tomorrow. Needs rings. Don't think the tractor is worth anything with a smoking engine and not attachments. Steering wheel was missing and don't have the right one. I think it is going to be a parts tractor, starting with a torch on the front motor mounts so I can get the clutch off, then remove the choke and throttle cables, amp gauge and key switch. Rest can wait for another day. Might throw a set of rings in the engine this winter just to have another horizontal shaft on hand. Have HH160 that is good, an 8 hp Wisconsin that needs rebuilt, and another Wisconsin 8 or 10 hp. status unknown.

Vanguard going in the Cub. Had to remove the front cross member with the hood to get at the clutch. Tried removing the bolt going into the end of the crank & all it did was spin ? ? Removed the four nuts that hold the plate over the clutch to the engine. Won't come off as the engine mounts are in the way. Have to pull the engine to remove the clutch.

I got dragged into helping a friend make heads or tails out of a Grasshopper 725k. It has a CH25 Kohler in it, I have never worked on one of those engines yet. The wiring is a mess, the worst I have ever seen, the PO added a ton of redundancy, and about 3 tons of butt connectors and scotchloks to the mix.

The 1st thing I need to know is that I have heard that some of those engines had an ignition system called SAM on them that is a pain to deal with, how do I know if this engine has it and can someone enlighten me on what it means and how it is supposed to work?

There is a module of some kind bolted to the base of the carb perpendicular to the choke and throttle shafts. What would this be/ it has a single red wire coming from it with a spade terminal on it. Will this engine run without it and where is that red wire supposed to go? It looks other wise like any other magneto electronic ignition only with separate coils for each cylinder, with a simple spade sticking out of each coil for a kill wire. It had that oil sentry on it at one point but that is MIA any more. And we don't care about adding it back in.

It also wasn't charging the battery but the middle wire to the regulator was dangling in the wind. I can figure that part out along the way, hopefully the stator and regulator are ok

Yep, the wire to the carb would be for the fuel solenoid, should be hot with ignition.

I use a GH 721D at church, it's a diesel, but the chassis wiring should be similar on some things, I can look at it if you need help.

I have to say I love using this thing to mow, much better than the big 72" cut Ferris we had.

Tahoe, the old unwritten rule holds true more times than not. The wider the deck, the bigger the chance of a uneven cut. I use a 50" deck and Carolyn uses a 42" deck, both on Cub Cadets. The 42" will give a more even cut than the 50". My lawn is uneven which makes that more noticeable.

Tahoe, the old unwritten rule holds true more times than not. The wider the deck, the bigger the chance of a uneven cut. I use a 50" deck and Carolyn uses a 42" deck, both on Cub Cadets. The 42" will give a more even cut than the 50". My lawn is uneven which makes that more noticeable.

It was not the unevenness of the cut, but more of the instability of the Ferris. It was a large heavy machine with a 32 hp Cat diesel, it was a great flat field mower. The bad part for us is we have a ton of hills, grades and a pond, mower ended up in pond 3 times from sliding. The grasshopper is lower and has 2 rear carrier wheels so the deck mounts are not part of the tractor itself like most front mount zero turns. I can drive this thing on a 35-40* hill without a worry of sliding.

our prices have dropped as well in most scrap productsTook the cans to the scrapyard and the price is down quite a bit now. I had 107 lbs of crushed cans and it was 35 cents a pound. $37 bucks and some odd change. Still worth it i guess but no sense waiting 'till the price goes up. Since my wife is unemployed for a while, my off work Mondays are not as efficient getting stuff done. She needed to do a few stops but I told her we are taking the '72 home as I want to put a few miles on her Denali to check for leaks. There was a slight dampness at the weep hole in the hydroboost that spooked me until it dawned on me that I didn't dry out the back of the brake master cylinder that was full of power steering fluid due to that leak. Sure enough, the weep hole was dry as a bone when we got back home, so that bit of fluid must have come out of the master cylinder piston cavity. Everything seems ok with it now. Ready for the 1000 mile round trip to Denver. We always use her truck because my sisters both have puny, uncomfortable little cars that we can't all fit in.

Greased the MF12G and put a new air filter on it for mowing today too.

DAC