Those die hard cub guys will tell you anything that is not back as stock is wrong. Got to have those rubber mounts to go bad and got to have thew jerk & bang Kohler single in them. Personally, I would not go back to rubber mounts on an engine again.I’m hoping to get my Cub 1250 back together over the winter. I’m thinking of doing a solid mount rather than the factory rubber mounts. I’ve asked dozens of Cub guys and most are one way or another.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your tractor today?

- Thread starter MFDAC

- Start date

first thing to knock on a K series is usually the rod/crank bearing.... Ive had one 321(lgt145) that snapped the rod and three 341s that were noisy enough I replaced them before selling the tractors... the 241s and 301s dont seem to have near as many issues I think mostly because the pistons are smaller/lighter so they simply dont wear as much after 40+ years of service. I tend to shy away from the 341s these days and I wouldnt rebuild one... a freshly rebuilt 241 has more usable power/torque than an old tired 341.

have to ask Noel... are you aware of the oiling hole in the rod journal that must be installed towards the camshaft side of the engine???

"Jerk and Bang Kohler Single" Lolol.... first Ive heard that.... but it does ring true for the bigger Ks

....those rubber engine mounts are often in bad shape on these old tractors but once you replace them they will last another 40 years and the tractor will be much quieter and feel smoother overall so I prefer them when ever possible.

have to ask Noel... are you aware of the oiling hole in the rod journal that must be installed towards the camshaft side of the engine???

"Jerk and Bang Kohler Single" Lolol.... first Ive heard that.... but it does ring true for the bigger Ks

....those rubber engine mounts are often in bad shape on these old tractors but once you replace them they will last another 40 years and the tractor will be much quieter and feel smoother overall so I prefer them when ever possible.

Last edited:

have to ask Noel... are you aware of the oiling hole in the rod journal that must be installed towards the camshaft side of the engine???

Yes Lance. I know about the oiler hole. Learned that lesson a few years ago when a engine blew up. Rod was put in backwards, by someone else. Found that when I took the engine apart.

Noel

Yes Lance. I know about the oiler hole. Learned that lesson a few years ago when a engine blew up. Rod was put in backwards, by someone else. Found that when I took the engine apart.

Noel

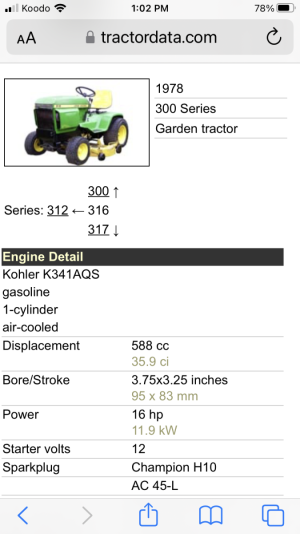

I got one out of a JD 316 for my 7012 that split the piston in. I had to change the flywheel. oil pan, and stator and had to modify the carb choke. Mounted solid in the 7012 it has more shake at midrange which could be the flywheel might need balanced for that engine.So. Wondering if this engine out of a 1978 316 John Deere would fit the ford LGT tractor I just put the motor in.

Any thoughts on this. Thanks

Noel

you would have to measure the output end on the crankshaft and check if the holes for mounting the pto are in the same place as those are often manufacturer specific... the flywheel, oil pan and rod cap/oil dipper are also probably differant but easily swapped.

buying any 341 is risky since they are all 40-50 years old and typically have alot of hours on them... and there is very little room to bore them out if needed.

buying any 341 is risky since they are all 40-50 years old and typically have alot of hours on them... and there is very little room to bore them out if needed.

I was all over the place today, so happy about being outside instead of painting. Started off with a fantastic breakfast, a western omelette with some homemade salsa, bacon, and toast with blackberry jam.

I cut down a 40’ section of my fence a year ago and left two bad posts. Today I used the Sears SS15 to pull these out. The first one I had to make several attempts at different angles. The second one popped out quickly.

We use the 250 gallon water totes sometimes when our cistern gets low. I have two but only use one so I took the other one up to the boneyard to get it out of sight.

When I worked on this tractors voltage regulator back in the summer I put one of the gas tank brackets on backwards. The hood would never close all the way. I finally changed that. Had to quit what felt early but I was running out of daylight…stupid time change.

I cut down a 40’ section of my fence a year ago and left two bad posts. Today I used the Sears SS15 to pull these out. The first one I had to make several attempts at different angles. The second one popped out quickly.

We use the 250 gallon water totes sometimes when our cistern gets low. I have two but only use one so I took the other one up to the boneyard to get it out of sight.

When I worked on this tractors voltage regulator back in the summer I put one of the gas tank brackets on backwards. The hood would never close all the way. I finally changed that. Had to quit what felt early but I was running out of daylight…stupid time change.

There are different block and oil pan configurations on those K321's, Noel. I found out because I had to buy a used oil pan for mine. Old one had a bad crack in it. Got the right pan, then I noticed my block wasn't originally intended to be used with the oil pan the MF1450 needed.

Someone had used some kind of steel putty and filled voids on the sides of the block that would have been covered by a different pan. I was in too deep, so I proceeded with the overhaul anyway. Finding a replacement engine around here was out of the question.

I didn't trust that there would be no seeping around or through that putty so gaskets were made to sandwich between the engine mount plates and the block where those voids are.

So far so good. That was only in March of this year, but the tractor did all my yard mule duties this summer and fall. No telling how long it might last.

DAC

Someone had used some kind of steel putty and filled voids on the sides of the block that would have been covered by a different pan. I was in too deep, so I proceeded with the overhaul anyway. Finding a replacement engine around here was out of the question.

I didn't trust that there would be no seeping around or through that putty so gaskets were made to sandwich between the engine mount plates and the block where those voids are.

So far so good. That was only in March of this year, but the tractor did all my yard mule duties this summer and fall. No telling how long it might last.

DAC

I have not yet seen a simple straight forward K series engne swap... there is always something, and sometimes several things, needing to be changed... and thats pretty much why I collect the 241/301 blocks... there is alot more of them around, generally in better condition than the 321/341... and they can be built up to 14+ hp using oem parts, I still end up swapping parts around but it opens up alot more options.

Noel are you gonna pull that 321 apart to see whats knockin??? I would guess its likely just a rod bearing

Noel are you gonna pull that 321 apart to see whats knockin??? I would guess its likely just a rod bearing

There are different block and oil pan configurations on those K321's, Noel. I found out because I had to buy a used oil pan for mine. Old one had a bad crack in it. Got the right pan, then I noticed my block wasn't originally intended to be used with the oil pan the MF1450 needed.

Someone had used some kind of steel putty and filled voids on the sides of the block that would have been covered by a different pan. I was in too deep, so I proceeded with the overhaul anyway. Finding a replacement engine around here was out of the question.

View attachment 61725

I didn't trust that there would be no seeping around or through that putty so gaskets were made to sandwich between the engine mount plates and the block where those voids are.

View attachment 61726 View attachment 61727

View attachment 61728

So far so good. That was only in March of this year, but the tractor did all my yard mule duties this summer and fall. No telling how long it might last.

View attachment 61729

DAC

Thanks Doug. Ya I know about the different blocks. I have two of those blocks here like what you put in your tractor.

Noel

number of years ago I picked up an openside lgt145, put alot of time into the tractor but the engine didnt sound too bad so I never actually looked inside of it.... lasted about 3 weeks of mowing and then the rod broke... I was not happy and Ive been very leary of any 321/341 since. Never did put another engine in that 145... saved all the hard to find parts and scrapped it when I moved a couple years ago.

...that was probably also the same day I decided I liked my 16hp B&S engines far more..Lol

...that was probably also the same day I decided I liked my 16hp B&S engines far more..Lol

the Briggs engines dont generally have the same conn rod issues as the Kohler so they are a little less risky, and they are fairly easy to adapt into most any tractor that uses an H-shaft... tricky part might be lining up the Ford drive shaft... and I would expect you need the Briggs pto on the front.

with Kohlers you can put a 321 crankshaft, rod and piston into a 241 block, even the 321 valves can be put in but the seats need to be replaced aswell.... and you can also use an LP head to gain another 1-2hp.... some people claim to have built 13fin 301s up to as much as 20hp but I havent built one that far...Yet

Brian Miller built the k181 in my Bolens RaM and it was reportedly dyno'd at 13.8hp.... its a very light tractor so traction is sometimes an issue but it does pull like it has 14hp and its as quiet as a sewing machine except for the straight pipe stack on it.

gardentractorpullingtips.com

gardentractorpullingtips.com

with Kohlers you can put a 321 crankshaft, rod and piston into a 241 block, even the 321 valves can be put in but the seats need to be replaced aswell.... and you can also use an LP head to gain another 1-2hp.... some people claim to have built 13fin 301s up to as much as 20hp but I havent built one that far...Yet

Brian Miller built the k181 in my Bolens RaM and it was reportedly dyno'd at 13.8hp.... its a very light tractor so traction is sometimes an issue but it does pull like it has 14hp and its as quiet as a sewing machine except for the straight pipe stack on it.

Professional Kohler Engine Information, Rebuilding, Buildups and Modifications

small engine repairs, kohler, carburetor, carburetor rebuilding, engine rebuild, ignition, ignition trigger kit, garden tractor pulling, cub cadet

gardentractorpullingtips.com

gardentractorpullingtips.com

Got some unwanted seat time today. Had a crappy day at work due to the 6+ inches of s-word, then had to come home and plow too! "They" said in the forecast "a trace to 1 inch". Missed that by a ways. MF8E worked great, but one headlight gave up. took about an hour but I didn't do the cleanest job either.

DAC

DAC

Don’t be like me Noel I have a K301 torn apart, cleaned, and parts needed ready to re assemble now for over a year. It’s a good thing I put a coat of thin oil on everything.Motor is out. It’s the one on the right. I’ll get it apart some day.

Noel