You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your tractor today?

- Thread starter MFDAC

- Start date

more,

OUR PROCESS

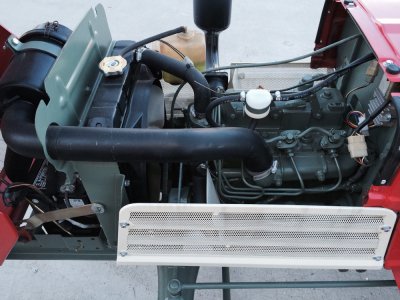

In the beginning, refurbishment was limited to minimal functional repairs, like replacing seats and batteries, and tuning up and cleaning engines. As we continued to refurbish tractors and take the process further, we also developed an aftermarket parts supply and inventory. Where parts were previously unavailable or in very limited supply, we now had a supply chain large enough to allow us to complete extensive repairs and refurbishments. This was the beginning of the Fredricks Difference.- New engine components and hardware, like sleeves, pistons, bearings, rods, and more.

- New radiators.

- New soft goods like belts and hoses.

- New electrical components.

- New starters.

- A full safety package.

- Fresh paint and bodywork.

- New grills, lights, and turn signals.

- New seals and fresh fluids.

- And much more!

- Seatbelt: Each seatbelt is bolted to the frame, to help keep you in the seat, safe and sound.

- English Operating and Safety Labels: These tractors were originally made in Japan and, therefore, had operating and safety decals writting in Japanese kanji. So, we replace them with bright, easy-to-read, english-language operating labels.

- PTO Shield: This shield covers the PTO assembly and helps to prevent unwanted and dangerous contact with the spinning PTO and implement driveshaft joint.

- PTO Overrun Clutch: Each tractor is supplied with a PTO overrun clutch. The clutch acts as a slip gear, much like the rear wheel of a bicycle. When force from the tractor PTO is applied, the overrun engages and spins the implement. When the operator stops the tractor, and the PTO, the clutch disengages, allowing the implement to spin down without turning the PTO. Without the overrun clutch, an implement that has a lot of inertia (like a rotary cutter) could drive the tractor forward.

- Clutch Safety Switch: This helps to prevent the starting of the tractor while it is in gear. Because the clutch must be engaged to crank the tractor, the transmission is fully disengaged and will remain stationary during start-up.

Should you need a machine, restored to Better Than New,

www.fredricksimporting.com

www.fredricksimporting.com

Our Process — Fredricks Importing

This is the UTDA center. It takes all of these Yanmar, Deere, etc machines and restores them to better than new. Next these are sent out to 5 locations in the southeast states to sell.How come so many of them in one place? Don't they sell very good?

There are two other companies doing this too. One in California and another in Washington.

They sell so many of them, it keeps the used tractor market booming for these machines. Certain models are on back order.

Last edited:

I took my FF24 to work with my box blade, the semis tear up our gravel lot when they turn. I used the teeth to tear it up some, then I pulled the excess gravel over into the pot holes. I then tried to smooth it all out, I need more practiced as I was digging the holes out more versus filling and grading, kept messing with the angles. I also broke the rear plate across the back used to smooth so that needs welded.

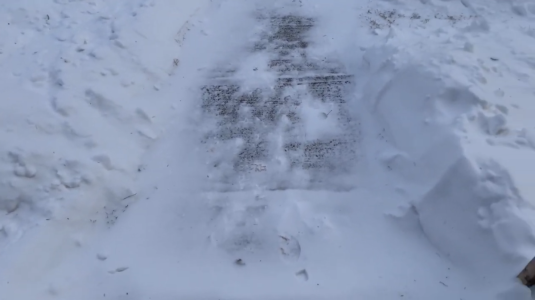

Some snow removal today with the 50 year old,1975 Case 224 with snowthrower. Not a lot of snow out of this storm. But some spots had to be cleaned up.

Tractor and thrower worked great.

Noel

Tractor and thrower worked great.

Noel

Attachments

-

IMG_0131.png795.3 KB · Views: 9

IMG_0131.png795.3 KB · Views: 9 -

IMG_0132.png1.2 MB · Views: 9

IMG_0132.png1.2 MB · Views: 9 -

IMG_0133.png830 KB · Views: 7

IMG_0133.png830 KB · Views: 7 -

IMG_0134.png713.5 KB · Views: 6

IMG_0134.png713.5 KB · Views: 6 -

IMG_0135.png1.1 MB · Views: 8

IMG_0135.png1.1 MB · Views: 8 -

IMG_0136.png1.1 MB · Views: 8

IMG_0136.png1.1 MB · Views: 8 -

IMG_0137.png992.9 KB · Views: 8

IMG_0137.png992.9 KB · Views: 8 -

IMG_0140.png1 MB · Views: 7

IMG_0140.png1 MB · Views: 7 -

IMG_0139.png1,016.1 KB · Views: 7

IMG_0139.png1,016.1 KB · Views: 7 -

IMG_0138.png932.1 KB · Views: 9

IMG_0138.png932.1 KB · Views: 9

I got both tractors ready Sunday for the snow storm. The thought crossed my mind, but I didn't do it....park one of the tractors up by carport so I ended up starting my plow day fighting getting stuck and sliding down the hill. I needed just enough to get around the Jeeps, finally after about 15 to 20 mins, managed to do it with the purple one, it needs weights so bad.

We ended up with about 10", my son had his company plow truck so he did the bottom half this morning, living on a sharp corner the county truck dump the snow in our driveway just from the forces in the corner.

I went to work for 2 hours, they sent us home, started plowing at 11:30, got done at 4:30.

Got tractor stuck a few times, one place where I ram snow I get it stuck every year.

Ran out of gas also, did my elderly neighbors drive and the guys across the street.

My normal bury it/get stuck spot.

We ended up with about 10", my son had his company plow truck so he did the bottom half this morning, living on a sharp corner the county truck dump the snow in our driveway just from the forces in the corner.

I went to work for 2 hours, they sent us home, started plowing at 11:30, got done at 4:30.

Got tractor stuck a few times, one place where I ram snow I get it stuck every year.

Ran out of gas also, did my elderly neighbors drive and the guys across the street.

My normal bury it/get stuck spot.

Looking good.Some snow removal today with the 50 year old,1975 Case 224 with snowthrower. Not a lot of snow out of this storm. But some spots had to be cleaned up.

Tractor and thrower worked great.

Noel

Your cousin seems to be a little camera shy.

Attachments

If I had been there I would have pulled you out.I got both tractors ready Sunday for the snow storm. The thought crossed my mind, but I didn't do it....park one of the tractors up by carport so I ended up starting my plow day fighting getting stuck and sliding down the hill. I needed just enough to get around the Jeeps, finally after about 15 to 20 mins, managed to do it with the purple one, it needs weights so bad.

We ended up with about 10", my son had his company plow truck so he did the bottom half this morning, living on a sharp corner the county truck dump the snow in our driveway just from the forces in the corner.

I went to work for 2 hours, they sent us home, started plowing at 11:30, got done at 4:30.

Got tractor stuck a few times, one place where I ram snow I get it stuck every year.

Ran out of gas also, did my elderly neighbors drive and the guys across the street.

My normal bury it/get stuck spot. View attachment 89686

View attachment 89687

Seems i owe you one for pulling me out of a sink hole at Daniels.

Good yank from the Dodge 2500 and she came right out.If I had been there I would have pulled you out.

Seems i owe you one for pulling me out of a sink hole at Daniels.

Only thing I did with my tractors was cover them up again.

Had four with snow plows ready for the big storm. Last Friday we got about an inch of snow. That was all we got thru today.

Went from forecasting 10-12 inches to nothing at all. Not even rain. Twenty miles south they got 5-6 inches. Farther south got even more.

Not complaining, just unusual.

Had four with snow plows ready for the big storm. Last Friday we got about an inch of snow. That was all we got thru today.

Went from forecasting 10-12 inches to nothing at all. Not even rain. Twenty miles south they got 5-6 inches. Farther south got even more.

Not complaining, just unusual.

Attachments

If I'm not mistaken my 2019 JD 2032 has a Yanmar engine in it. During the China flu I needed a tractor and wasn't looking for a JD particularly but this one turned up with 40 hours so I grabbed it. As of today I'm certainly happy with the purchase. Been an excellent tractor.Mine was restored back in 2014 from the ground up.

YM2610 unloaded from a sea shipping container.

To the best of my knowledge everyone I know of has been happy with Yanmar products old or new.

Last edited:

We got maybe 2.5" then we only got a half inch more and I don't evben have a blade on a tractor. If we get enough snow that need removed the neighbor across the street is always up early and blows our drive out.

I am having a good day as the print isn't blurry.

I am having a good day as the print isn't blurry.

Glad your day was good, Rad!We got maybe 2.5" then we only got a half inch more and I don't evben have a blade on a tractor. If we get enough snow that need removed the neighbor across the street is always up early and blows our drive out.

I am having a good day as the print isn't blurry.

DAC