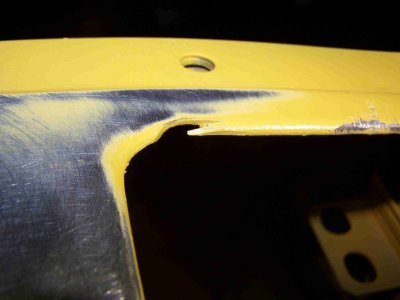

Spent about an hour on the John Deere 730 parts. Sanded the fenders to see what and if I need to smooth out and fill anything. Just a couple place need work. Then onto the hood. Started working the metal around the openings. I think I have it good enough to just prime and sand with no filler. I can tell I am out of practice doing this stuff but its slowly coming back.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Workin' on the Old Tractors

- Thread starter cjet69

- Start date

I'd bet Cjet your paint repairs are probably better than what factory finishes were...Spent about an hour on the John Deere 730 parts. Sanded the fenders to see what and if I need to smooth out and fill anything. Just a couple place need work. Then onto the hood. Started working the metal around the openings. I think I have it good enough to just prime and sand with no filler. I can tell I am out of practice doing this stuff but its slowly coming back.

My brother showed up today so we tore the Case IH 485 starter apart. The brushes are wore right down to where the wires were starting to rub. Lots of build up on the brush holder and commutator. Now to decide if we want to clean it up and solder in new bushes or just buy a new starter.

Attachments

-

100_7028-m.JPG204 KB · Views: 10

100_7028-m.JPG204 KB · Views: 10 -

100_7029-m.JPG183.6 KB · Views: 10

100_7029-m.JPG183.6 KB · Views: 10 -

100_7031-m.JPG200.1 KB · Views: 8

100_7031-m.JPG200.1 KB · Views: 8 -

100_7033-m.JPG179.9 KB · Views: 8

100_7033-m.JPG179.9 KB · Views: 8 -

100_7034-m.JPG212.2 KB · Views: 8

100_7034-m.JPG212.2 KB · Views: 8 -

100_7035-m.JPG188.7 KB · Views: 8

100_7035-m.JPG188.7 KB · Views: 8 -

100_7036-m.JPG208.9 KB · Views: 7

100_7036-m.JPG208.9 KB · Views: 7 -

100_7038-m.JPG251.6 KB · Views: 7

100_7038-m.JPG251.6 KB · Views: 7 -

100_7040-m.JPG214.2 KB · Views: 10

100_7040-m.JPG214.2 KB · Views: 10

Looking at the inside of the starter one would hardly think it would ever work again..My brother showed up today so we tore the Case IH 485 starter apart. The brushes are wore right down to where the wires were starting to rub. Lots of build up on the brush holder and commutator. Now to decide if we want to clean it up and solder in new bushes or just buy a new starter.

The way this is made you would need to solder the 2 positive brushes in which is kind of a pain. Then I would wonder if something else is ready to fail. With a new I would just bolt it in and go with all new parts. I need to check with a local supplier but online I can get a new starter for around $200 with tax and shipping. I'll do more searching online for parts before I decide.Dang CJet amazing it worked at all! Even if you bought a new one, I'd be willing to bet you will repair this one too!

DAC

Had a few time where I had to try it 5-10 times before it would turn over enough to start. When we pulled it apart it had that smell like it had been hot. This is the original starter and I think the tractor is a 1990 model. At least it made it through last hay season before it died.Boy I can't believe that starter worked at all you got your moneys worth from those brushes

I doubt any of our short hills would be big enough for the diesel tractors. Pretty much have to pull start out on the road if you can keep the wheels from sliding. We even have that trouble with the gas burners.Providing everything you have has a clutch just park on a hill and you won't need those dang starters...

Some reason Cjet I think you might have a small incline near by...

Did a little shrinking and welding around the right side square muffler opening on the John Deere 730 hood. Knocked the weld down with a grinder and will finish it off with a file to get it nice a straight. Hit a couple other spots with the bullseye pick and its just about ready for primer. Tomorrow I will get the second fender smoothed out. Its just a small area and shouldn't take much.

Attachments

Since I am going to be spraying some paint soon I thought I should get the bulb changed in my infrared heat lamp that was broken in shipment. It only took me just under a year to get it done.  I've used it several times with just one working bulb and it worked fine but with the 2 bulbs going it feels like it more than doubles the heat. Really warms surfaces better now.

I've used it several times with just one working bulb and it worked fine but with the 2 bulbs going it feels like it more than doubles the heat. Really warms surfaces better now.

Attachments

Where did you end up getting the starter ?Bought a new aftermarket starter for the Case IH 485 yesterday. I got it installed today and the tractor starts good again.

Seems on certain aftermarket parts they're either tons available or barely any. Then the quality is hit or miss.

Got it from a local equipment parts supplier. I said aftermarket but meant remanufactured.Where did you end up getting the starter ?

You do know IR heating elements are rated to a max of 5,000 running hours right? The expensive ones last till 10,000 working hours.Since I am going to be spraying some paint soon I thought I should get the bulb changed in my infrared heat lamp that was broken in shipment. It only took me just under a year to get it done.I've used it several times with just one working bulb and it worked fine but with the 2 bulbs going it feels like it more than doubles the heat. Really warms surfaces better now.

So, what I'm getting at is this, do not use it for 24/7 in the winter. Plan your outside building projects wisely.

The cost is cheap though to run it 24/7 if the Kw rate is 13-cent per hour, thus 1,500W is 5-bucks.

This is used to cure the paint and not heat the shop. Normal run times will be around 20/30 minutes. Keeping the shop at 60°F when its mid 40's outside will burn a lot of propane along with the wood heat. The IR heat lamp will also allow me to cure the paint on John Deere tractor where I need to spray yellow over the green without waiting a week for it to air dry it. The John Deere paint will wrinkle if you apply the second color to soon. In summer I just set it out in the sun for a day and its good to go.You do know IR heating elements are rated to a max of 5,000 running hours right? The expensive ones last till 10,000 working hours.

So, what I'm getting at is this, do not use it for 24/7 in the winter. Plan your outside building projects wisely.

The cost is cheap though to run it 24/7 if the Kw rate is 13-cent per hour, thus 1,500W is 5-bucks.

Pulled the Grille for the JD 730 apart today. Found some old garage door track bracing to brace the grille with and keep it from flopping around while I work on it. With the screens removed I found some more surface rust that needs to be cleaned up.

Attachments

-

100_7104-m.JPG200.1 KB · Views: 11

100_7104-m.JPG200.1 KB · Views: 11 -

100_7110-m.JPG217.5 KB · Views: 11

100_7110-m.JPG217.5 KB · Views: 11 -

100_7111-m.JPG163.8 KB · Views: 8

100_7111-m.JPG163.8 KB · Views: 8 -

100_7115-m.JPG226.1 KB · Views: 8

100_7115-m.JPG226.1 KB · Views: 8 -

100_7116-m.JPG175.3 KB · Views: 8

100_7116-m.JPG175.3 KB · Views: 8 -

100_7126-m.JPG181 KB · Views: 8

100_7126-m.JPG181 KB · Views: 8 -

100_7127-m.JPG164.2 KB · Views: 8

100_7127-m.JPG164.2 KB · Views: 8 -

100_7128-m.JPG180.1 KB · Views: 8

100_7128-m.JPG180.1 KB · Views: 8 -

100_7132-m.JPG110.7 KB · Views: 8

100_7132-m.JPG110.7 KB · Views: 8 -

100_7136-m.JPG184.1 KB · Views: 11

100_7136-m.JPG184.1 KB · Views: 11

Stripped the inside of the flywheel cover and treated it with Ospho. Stuck it under the heat lamp for 10 minutes to dry it after treatment.