First photo is the pas side of the carb with the engine side point to lower right.

Second shows the bottom of the carb with the pilot in the center in front of the float chamber and just back of the engine side intake.

Third is the driver side w/carb installed.

Fourth is Passenger side w/carb installed.

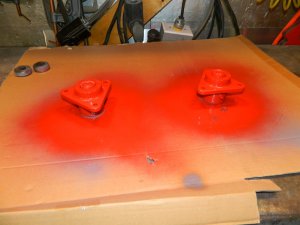

Last is the tool I made to get in the pot to adjust the pilot.

Had to insert the tool using a finger from each hand on each side of the carb, as that is all there is room for. Then rotate the tool till it fell up into the slot in the pilot and turn it a bit. Then turn the idle acrew to slow the idle down. Then back to the pilot adjusting again. As you can see there is very minimal room to do any adjusting. A flex shaft screw driver would work IF I had one small enough to fit in the slot and hole in the carb body. Polaris has special tools for adjusting the pilot and the idle screw. In the third photo, right in the center of the photo the small shiny black tube is the carb drain line. The long screw that is sticking down just to the right of the drain line is the idle adjusting screw.