You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you currently working on??

- Thread starter backwoods

- Start date

Gonna mow today too before the Bears game, won't be the last time, even if it frosts, as leaves have barely started to fall. I sometimes run the mower every other day when leaf season gets underway. Just made up a fresh batch of lawn boy mix yesterday just for leaf season. Anything that I can do to keep from having to rake them without just leaving them lay over the winter. I hate leaf harvest season with a passion. Always have. I did pick up a well used and worn out 8hp lawn vacuum for a song a couple of months ago. Gonna try that out this year too.

If it blows up it blows up,I have very little into it. I used to have a 5hp version until it fell out of the back of a truck some years ago. But while it lasts I won't have to rake.

If it blows up it blows up,I have very little into it. I used to have a 5hp version until it fell out of the back of a truck some years ago. But while it lasts I won't have to rake.

I have taken to running 2 grounds, 1 from a mounting bolt from the engine. straight to the battery, another from the battery to somewhere on the frame, both are the same gauge wiring as I use from the battery to the solenoid and from there to the starter.Updated the grounds on the Craftsman Pro. This way I am not relying on the chassis bolts for 100% ground connection from the battery to engine block.

I got the MF8E set up with the yard cart to spread gravel tomorrow, BUT I may be pushing snow instead! Started snowing hard around 3pm, and its been rainy all day anyhow. I was getting 4 tons of 3/4" delivered in the morning but I may be just having to get them to pile it if they will be able to deliver at all. I may have to put the blade skids back on for snow removal instead!

DAC

DAC

I have a Yamaha 2X4 ATV that smokes like a mad Indian. Other than that it starts and runs great. Just don't stand or follow behind the exhaust. Was looking to update but dealer prices were crazy. Found this range private, needed some work so grabbed it. New carb, replaced everything on the rear brakes except the calipers, replaced all 4 tires and a few other minor things. Hardley use the ATV any more as this is much handier.That’s a good size Roger. It would be very handy.

Noel

Wood shop work this afternoon. Step daughter & her boyfriend moved into a house with a pool table. Nothing else just the table. I had an extra set of pool balls, a few cues, rack & chalk. Enough to get them going. I gave them the rack so now I am in the process of putting a rack together. Have clamps on the 3 inside corner blocks and the outside is stuck together.

Yesterday after work i did some outside stuff since it was so darn nice out and "they" said today would suck. Even though there's water flowing in the ditch out front again I noticed a bunch of carboard had blown into it besides leaves. Got the garbage out at least. Put the thermostat for the heat lamp in the well house since it looks like days are coming that will not get above freezing. Moved some of my wife's yard decorations into one of the sheds and a bunch of other small stuff.

Today "They" were right. Weather sucks now. Good shop time. I got the exhaust off of the MF8E to weld the muffler that broke last Monday spreading gravel and then remembered I'm about out of argon. Opened the valve and the bottle pressure was zero, but regulated pressure was still good. There was just enough left to weld that muffler! Cleaned it up and gave it a fresh coat of black bar-b-q grille paint. I'll fill the bottle Monday. Put the exhaust and the skids back on the MF8E just in case we get more snow than forecasted.

The airbag sensor for my wife's '06 Denali came in yesterday so I got her truck in the shop to change that. I also lubed the front suspension since I had it up on the ramps and the front splash guard off. Air bag light and digital warning is off so all is good again for now!

DAC

Today "They" were right. Weather sucks now. Good shop time. I got the exhaust off of the MF8E to weld the muffler that broke last Monday spreading gravel and then remembered I'm about out of argon. Opened the valve and the bottle pressure was zero, but regulated pressure was still good. There was just enough left to weld that muffler! Cleaned it up and gave it a fresh coat of black bar-b-q grille paint. I'll fill the bottle Monday. Put the exhaust and the skids back on the MF8E just in case we get more snow than forecasted.

The airbag sensor for my wife's '06 Denali came in yesterday so I got her truck in the shop to change that. I also lubed the front suspension since I had it up on the ramps and the front splash guard off. Air bag light and digital warning is off so all is good again for now!

DAC

Last edited:

I've been working on my Firebird a little this week, blew brake line and needed a rotor. Gotta finish up today and get it out of carport and driving.

Yesterday, the son and I cut down a leaning hackberry tree. The upper limbs were hanging over his firepit, he was worried he was going to catch the whole tree on fire. Came down exactly where I wanted, taller than we expected I cut until the saw ran out of fuel. It was good though, rain was getting pretty heavy, we were both already pretty soaked. Had to get done though.

Today I will he putting first coat of sealer on my cistern, gotta get that done before it gets too cold, I dont want to haul water all winter.

Yesterday, the son and I cut down a leaning hackberry tree. The upper limbs were hanging over his firepit, he was worried he was going to catch the whole tree on fire. Came down exactly where I wanted, taller than we expected I cut until the saw ran out of fuel. It was good though, rain was getting pretty heavy, we were both already pretty soaked. Had to get done though.

Today I will he putting first coat of sealer on my cistern, gotta get that done before it gets too cold, I dont want to haul water all winter.

Today it was time to start on rebuilding the other two deck spindles on the MF12G. I had to do one about mid summer. Crappy outside, so a good job to do while Martinsville was on! One pulley would not come off so it had to be cut. The puller bent the heck out of it any way. I have a few extras thanks to Ted, @esbbent . I tried to get the pulley off of the gearbox too, and it wouldn't budge either. I decided that after cleaning up the deack everything can still be painted with it on. Hopefully I can take it to work next weekend and use the pressure washer there. It has much more pressure than mine and it's inside. Mine is winterized. All 3 spindles still feel real good so should be in nice shape for an overhaul and add grease zirks. There's some bracket holes that are wallerd out and those will get tightened up and hopefully I can come up with an idea for the front anti-scalp roller. It's pretty loose. Here's a few pics.

DAC

DAC

Need to replace the starter motor on my Polaris Ranger. Got the air tube for the clutch off and noticed the belt was up side down - unless that belt had the cross ribs on both sides ? ?

Lucked out on the belt. Aftermarket brand, good quality that is designed that way so the belt is good to go. Now to start working on getting the starter motor out.

Starter motor is the round item center picture under the hose.

The other end with the bottom bolt shiny in center pic.

Shows the positive wire stud near center pic.

Had to wrap a short 10mm wrench with rubber electrical tape to build it up and give something to grip. 37° Hands got cold so had to warm them up and go again. Could only turn that bottom bolt 1/2 flat at a time. Had to cut away part of the plastic on the inside of the belt cover to get it to turn all the way out. A good 5/8" of threads was turned into the block. Will shorten the bolt when the new starter goes in to eliminate that issue. Once it was unbolted, had to turn it 1/2 rotation as the mounting ears would not allow it to tip far enough to come out. Finally got it out, gear teeth look good. Hooked it up to a 10 A charger and touched the + stud. Started to growl and turn the the breaker in the charger tripped. New starter to be here Thursday.

Had to wrap a short 10mm wrench with rubber electrical tape to build it up and give something to grip. 37° Hands got cold so had to warm them up and go again. Could only turn that bottom bolt 1/2 flat at a time. Had to cut away part of the plastic on the inside of the belt cover to get it to turn all the way out. A good 5/8" of threads was turned into the block. Will shorten the bolt when the new starter goes in to eliminate that issue. Once it was unbolted, had to turn it 1/2 rotation as the mounting ears would not allow it to tip far enough to come out. Finally got it out, gear teeth look good. Hooked it up to a 10 A charger and touched the + stud. Started to growl and turn the the breaker in the charger tripped. New starter to be here Thursday.

Service manual says to remove the outside belt cover, then remove the drive clutch which requires a special Polaris tool at $80 +. Then remove the driven pulley so one can get at the bolts to remove the inside of the belt cover to allow that bottom bolt to come out. Now how stupid of a design is that ? ?

PS: I need a photo editor that don't take 6 months to learn and and only use rarely so you forget how to run it.

Lucked out on the belt. Aftermarket brand, good quality that is designed that way so the belt is good to go. Now to start working on getting the starter motor out.

Starter motor is the round item center picture under the hose.

The other end with the bottom bolt shiny in center pic.

Shows the positive wire stud near center pic.

Had to wrap a short 10mm wrench with rubber electrical tape to build it up and give something to grip. 37° Hands got cold so had to warm them up and go again. Could only turn that bottom bolt 1/2 flat at a time. Had to cut away part of the plastic on the inside of the belt cover to get it to turn all the way out. A good 5/8" of threads was turned into the block. Will shorten the bolt when the new starter goes in to eliminate that issue. Once it was unbolted, had to turn it 1/2 rotation as the mounting ears would not allow it to tip far enough to come out. Finally got it out, gear teeth look good. Hooked it up to a 10 A charger and touched the + stud. Started to growl and turn the the breaker in the charger tripped. New starter to be here Thursday.

Had to wrap a short 10mm wrench with rubber electrical tape to build it up and give something to grip. 37° Hands got cold so had to warm them up and go again. Could only turn that bottom bolt 1/2 flat at a time. Had to cut away part of the plastic on the inside of the belt cover to get it to turn all the way out. A good 5/8" of threads was turned into the block. Will shorten the bolt when the new starter goes in to eliminate that issue. Once it was unbolted, had to turn it 1/2 rotation as the mounting ears would not allow it to tip far enough to come out. Finally got it out, gear teeth look good. Hooked it up to a 10 A charger and touched the + stud. Started to growl and turn the the breaker in the charger tripped. New starter to be here Thursday.Service manual says to remove the outside belt cover, then remove the drive clutch which requires a special Polaris tool at $80 +. Then remove the driven pulley so one can get at the bolts to remove the inside of the belt cover to allow that bottom bolt to come out. Now how stupid of a design is that ? ?

PS: I need a photo editor that don't take 6 months to learn and and only use rarely so you forget how to run it.

Last edited:

I had to change a starter on a Ranger at work a couple months ago---that job sucks bad, Roger! At least I was getting paid to do it, and I didn't have to worry about flat-rate time.

I didn't get a lot of shop time today, but still tinkered for a couple of hours. I had an early afternoon doc appointment so I went to the welding shop and filled the argon tank, an auto parts store and still had to kill some time. I went to tractor supply to just look around, hadn't been there for awhile. Was checking out mower blades just to see if by some chance there was something that may fit the MF cutting deck. None of course but I bought one of those drill sharpening doo-dads that you stick in a drill. I figured for 8 bucks what the heck.

Got home after the appointment and tried it out. My blades were pretty nice shape anyway, but the angle on the stone fit the blades perfect even though I've used a grinder all along. Looks like it will work ok.

Then I fought the stuck pulley hub for awhile that I had to cut up yesterday to get out of the deck and finally got the stupid thing off without damaging the shaft. Had to drive a pickle fork in to move it enough where I could split the hub with a cutoff wheel. I want to use that shaft as it was sill nice and tight so I'm guessing that it's in good condition. Going on call at work tomorrow for a week so probably won't get a lot done for awhile.

DAC

I didn't get a lot of shop time today, but still tinkered for a couple of hours. I had an early afternoon doc appointment so I went to the welding shop and filled the argon tank, an auto parts store and still had to kill some time. I went to tractor supply to just look around, hadn't been there for awhile. Was checking out mower blades just to see if by some chance there was something that may fit the MF cutting deck. None of course but I bought one of those drill sharpening doo-dads that you stick in a drill. I figured for 8 bucks what the heck.

Got home after the appointment and tried it out. My blades were pretty nice shape anyway, but the angle on the stone fit the blades perfect even though I've used a grinder all along. Looks like it will work ok.

Then I fought the stuck pulley hub for awhile that I had to cut up yesterday to get out of the deck and finally got the stupid thing off without damaging the shaft. Had to drive a pickle fork in to move it enough where I could split the hub with a cutoff wheel. I want to use that shaft as it was sill nice and tight so I'm guessing that it's in good condition. Going on call at work tomorrow for a week so probably won't get a lot done for awhile.

DAC

I guess you could say I was getting paid as I didn't have to put out $$ to get the job done. Why they had to have that bottom bolt that long is beyond me. 4 or 5 threads is enough to hold the starter in place on the bottom. It will be shorter when it goes back together.

I have seen those blade sharpeners and bet they would work good for a touch up. I might have one around some place I think - was in a box from an auction. 4" angle grinder is laying right by the vise so guess what I grab first.

I have seen those blade sharpeners and bet they would work good for a touch up. I might have one around some place I think - was in a box from an auction. 4" angle grinder is laying right by the vise so guess what I grab first.

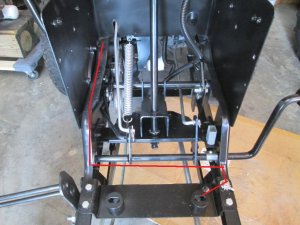

Tractor comes home and now is ready for that stuff. Every thing is on and all works. Hope I don’t have to use it.

Noel

Noel

Attachments

-

C4D379AA-7134-4BC7-9332-113964D8CB87.jpeg178.9 KB · Views: 5

C4D379AA-7134-4BC7-9332-113964D8CB87.jpeg178.9 KB · Views: 5 -

F052207B-C8CF-4F03-9E49-29E8015EF491.jpeg181.5 KB · Views: 5

F052207B-C8CF-4F03-9E49-29E8015EF491.jpeg181.5 KB · Views: 5 -

9444F81A-C5F3-454D-ACBE-7E386ADAEC57.jpeg198.1 KB · Views: 5

9444F81A-C5F3-454D-ACBE-7E386ADAEC57.jpeg198.1 KB · Views: 5 -

A0D5DB23-C161-40C9-9D31-849C7CCE0895.png1.2 MB · Views: 5

A0D5DB23-C161-40C9-9D31-849C7CCE0895.png1.2 MB · Views: 5 -

CDC0FB39-9802-4D70-86B3-54F7C6C0D96F.jpeg148.7 KB · Views: 5

CDC0FB39-9802-4D70-86B3-54F7C6C0D96F.jpeg148.7 KB · Views: 5 -

F58C3780-D9E8-4BFD-8335-76D02E4F39C5.jpeg146 KB · Views: 5

F58C3780-D9E8-4BFD-8335-76D02E4F39C5.jpeg146 KB · Views: 5 -

E832FD71-6CC6-4E9B-AB6A-26C1960C0AC3.jpeg115.7 KB · Views: 5

E832FD71-6CC6-4E9B-AB6A-26C1960C0AC3.jpeg115.7 KB · Views: 5 -

1748228D-46D5-46DC-8F54-CF8922F5CF06.jpeg155.5 KB · Views: 4

1748228D-46D5-46DC-8F54-CF8922F5CF06.jpeg155.5 KB · Views: 4 -

5055F345-BFB9-43D4-8477-6512ECE3096C.jpeg135.8 KB · Views: 4

5055F345-BFB9-43D4-8477-6512ECE3096C.jpeg135.8 KB · Views: 4 -

98E6B13F-6F64-4CE4-811C-3FB0809E71FA.jpeg141.1 KB · Views: 4

98E6B13F-6F64-4CE4-811C-3FB0809E71FA.jpeg141.1 KB · Views: 4

Next project is the JD 140. Service it for winter, put two more throwing paddles on the thrower, like I did on the Ford LGT 165 thrower and like on the MF 12 thrower. Not as easy on the JD thrower, I think. Have to get a good look and do some thinkin. And have to straighten rear blade on the JD 140. Lots to do.

Noel

Noel

Attachments

I found that the space between the paddles and the housing is a bigger issue than the number of paddles. I put belting on the paddles so they just clear and they throw a lot better. Did my BCS and Bolens like that a couple years ago. The Cub throweer has 4 paddles and they are close enough to the housing I don't think I could improve them enough to be worth while.

The new starter showed up about 5:20 last evening. At 27° F this morning going to have to get the torpedo heater fired up in the garage to work in there this morning. Will probably wait till later this morning to start the install as that will be at least a couple or 3 hours task.

Temp went the wrong direction 23° F now. Got the heat moved and ready to go, slid the foam board over the roof squirrel cage vent. Went to get a couple nuts o to put on the bolt before I cut it off and found a new metric bolt that is 1/4" shorter, just what I needed. With a lock and flat washer on it still have 4 full threads, 5 when the lock washer gets torqued down. I think I am good to go, at least for a while.

Well. I finally did it. Seen many many videos on this, for years now, and all people say it works and helps. And many on here say it’s good. I still can’t see how it will make that much difference. And if it does, why are the manufactures not doing it.

I installed the rubber paddles on my John Deere #49 thrower. Used an old front tire off my yard king ride on lawn tractor. May have to trim rubber, but it’s tight to turn it. Have to wait and see. They may wear in, which would keep them tighter. Don’t want to cut to much off, would be defeating the purpose of closing the gap.

Any way, have to wait for that stuff to try it. Hopefully it’s a long wait.

I’m going to look at the auger gearing when I have the side cover off to oil and check conditions of cogs and chain. I may speed up the auger, but my thinking is, it will bog down the thrower and engine revs will drop.

Any thoughts on these paragraphs ?

Noel

I installed the rubber paddles on my John Deere #49 thrower. Used an old front tire off my yard king ride on lawn tractor. May have to trim rubber, but it’s tight to turn it. Have to wait and see. They may wear in, which would keep them tighter. Don’t want to cut to much off, would be defeating the purpose of closing the gap.

Any way, have to wait for that stuff to try it. Hopefully it’s a long wait.

I’m going to look at the auger gearing when I have the side cover off to oil and check conditions of cogs and chain. I may speed up the auger, but my thinking is, it will bog down the thrower and engine revs will drop.

Any thoughts on these paragraphs ?

Noel