I don't mind snakes at all Marty, as long as they are OUTSIDE---LOL! I catch bullsnakes at work and bring them home to help with rodent control but soon as I turn them loose in the yard, they are on their own!

Pretty creative building the heating pad for the critter. How about using a heated seat element? they are pretty cheap but are 12 volt.

DAC

Snakes or other reptiles actually make good pets for people who have dog, cat or animal allergies. We feed our snake about every 10 days, spot clean the cage once or twice a week and give fresh water, so low maintenance animals.

This heat tape is pretty cheap and designed for use to heat enclosures. The most expensive part is the thermostat and you can find them for about $25.

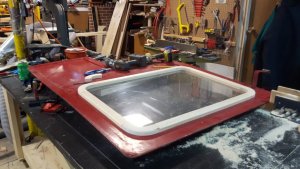

Many breeders keep their snakes in plastic tubs in large shelved racks. They just cut one long strip and place it under a row of tubs, easy and cheap. Our enclosure is more a natural vivarium so I had to enclose the heat tape inside something the snake can lay on without getting burnt, works pretty well.