In those situations I just shift a lever and let the front wheel do the work.I have my duels at about 5 lbs air with 3 rail chains and 50 lb wheel weights. If I load 6 bags of stove pellets for 240 lbs it can move on dry ground but is totally helpless in snow.

Don

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do with your tractor today?

- Thread starter MFDAC

- Start date

Would do that if I could find real weights but around here all I can find is the cheep sand filled plastic crap.Weight bench weights with brake rotors work nice as the 15lb weights fit inside most of the rotors so more weight in less space.

Don

My 1970s Craftsman is a little more primitive than that.In those situations I just shift a lever and let the front wheel do the work.

Have a couple here but only 11 lbs each. Considering the hat shape and the space they take up I haven't tried them.Check with your auto repair shop. They may have some brake rotors they will give you. I asked if I could have my old ones and he said sure, want some more? Ended up with 5.

Don

Led lights probably made the camera think it was bright enough so eliminated the flash. some times the light sensor reads the light shining on the camera instead of the light reflecting off the subject. Have to make sure the light source is behind you.

I will need to investigate. There are at least hundreds of different brake disks. The two I have are from the rear of a Subaru Outback and so have a brake drum section for the parking brake.

The actual disk section is not ventilated so solid and heavy. I will look around and see what I can find.

Don

I will need to investigate. There are at least hundreds of different brake disks. The two I have are from the rear of a Subaru Outback and so have a brake drum section for the parking brake.

The actual disk section is not ventilated so solid and heavy. I will look around and see what I can find.

Don

The 3 on the right and the outside on on the left are the same size and can off my 09 Silverado 1500, All three of them have a smaller weight bench weight insdie the hub area. Can see the edge of the one on the right. Don't know why the phone camera wanted to go dark. Had the LED lights on inside. View attachment 71557

GIMP 2.10 Auto Enhanced.

Working towards removing the top half of the steering unit off my Cub 1862. That CV joint can be problematic so starting with it first as it is the easiest. The CV joint is the tilt steering part of the system. Have to cross bolt soaking in PB now. Getting warm out there and my back is tired so quit for the day.

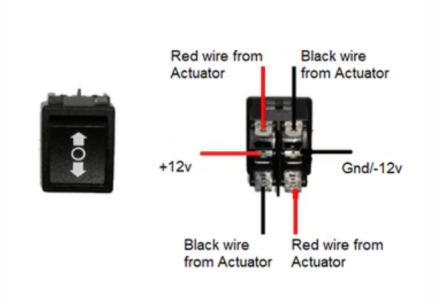

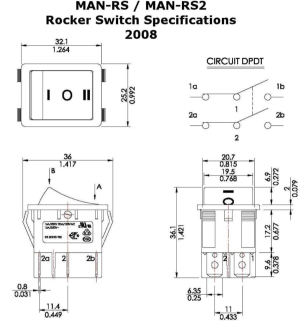

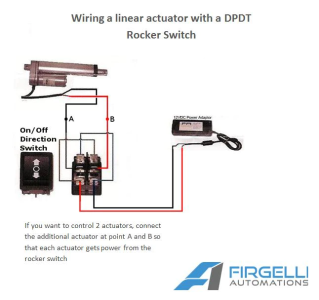

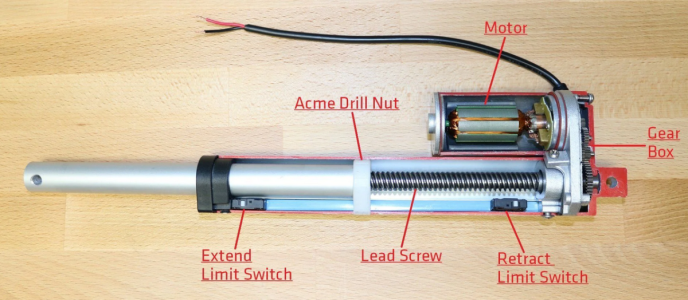

All you need is a DTDP switch mounted on the dash and wired properly. Then it's all easy.In stalling linear actuator on GT 235. I still have some debugging to do, but it lifted my 270 lb. butt.

One way goes up, the other down and the middle position has no rocker direction to apply power in either direction.

ideal size type,

Rocker Switches for Linear Actuators

Firgelli Automations Rocker Switches for Linear Actuators can provide Momentary and Sustaining motion ideal for most actuator projects.

Last edited:

You did smart going with an electric linear actuator. Typically get one that's 1.5X to 2X the strength you need. Basically it's the drive ratio vs speed on these things. The more torque these have the higher the ratio gear. So a 10:1 is weaker over a 20:1 or 30:1.I already have the switch and wired. Just haven't mounted it yet.

Depending on brand and options, many of the zero-turn mowers with unlimited deck height ability are linear actuators. These are more rugged and weatherproofed too. Deere uses these on several lawn tractors and compact tractors with belly mowers.

If you can mount the base of the linear actuator with a composite urethane suspension bumper or grommet to take the shock and jarring, the longer the unit will last.

Why do I know these dumb things. LOL, well, I was a commodity supplier of linear actuators to Granger and Motion Industries in a past career.

Got the CV joint out of the steering on the Cub 1862. Was dry and full of crud and very little gears anywhere. Got it cleaned up, only 2 steel balls so rotated the drive part and using a fresh set of sockets for the balls. Filled with CV joint grease and it is back together on the tractor. Wish I knew if I could run the Kohler Mag18 without all the wiring hooked up. then I could test the whole steering system out to make sure it is right. If I have to rebuild the main unit all that is off now has to come off again. Be nice to save a couple hours work. Any suggestions ? ?

Got the MF1450 out to do some hauling. Picked up the cutting deck for the JD110. I had it sitting outside upside down and rain water softened the gunk nice enough to scrape out with a putty knife and then haul it out into the grass to wash it off better.

There is more posted on the "And More Junk" thread that doesn't quite fit this thread.

DAC

There is more posted on the "And More Junk" thread that doesn't quite fit this thread.

DAC