You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you currently working on??

- Thread starter backwoods

- Start date

Looking good Lowell. That knee must be working out well for you.

It's getting there, brace is still locked straight, makes it hard to do work below ground level. I wanted to get it done before the rain started!

Update on the leakin husqvarna chainsaw. !!!!! I put it all back together. Started it up and ran it for a few minutes, on idle and full throttle and any where in between. So, I snuck up on it today and flipped it over to see the leak , and there was none. Been sittin for over 24 hours since yesterday and no leak.

Noel

Noel

Good deal Noel! I better get my saw out and get it fired up after this cutting deck job is done.

I got the epoxy coating painted on the underside of the deck today after a bit more sanding and cleaning. Yeah it's got a lot of brush strokes but I laid it on pretty heavy. If it's cured tomorrow it will be time to prep and spray the outside. Get that curing, rebuild two more spindles then it will be ready to assemble and install on the MF12G!

DAC

I got the epoxy coating painted on the underside of the deck today after a bit more sanding and cleaning. Yeah it's got a lot of brush strokes but I laid it on pretty heavy. If it's cured tomorrow it will be time to prep and spray the outside. Get that curing, rebuild two more spindles then it will be ready to assemble and install on the MF12G!

DAC

Last edited:

I hate B&S Vanguards! Got one here that needs a starter. Of course, one bolt is behind the starter bendix. Gotta take the flywheel and a cover off beneath it to get to the bolt! Dumb! All they needed to do was move that bolt out a little further and you could change a starter in just a few minutes!

To anybody who read my posts about my leaking Husqvarna chainsaw. Disregard anything I said about having maybe fixing the leak . Its now leaking again .

So it didn't leak a drop for those few days and now its leaking the same as it always was. I guess its beeped. Figures, I kinda thought it would do that.

So it didn't leak a drop for those few days and now its leaking the same as it always was. I guess its beeped. Figures, I kinda thought it would do that.

Ideas.

Noel

Ideas.

Noel

Attachments

Last edited:

To go along with this, I took the starter apart and found this.I hate B&S Vanguards! Got one here that needs a starter. Of course, one bolt is behind the starter bendix. Gotta take the flywheel and a cover off beneath it to get to the bolt! Dumb! All they needed to do was move that bolt out a little further and you could change a starter in just a few minutes!

This is a steel gear starter. I have another (plastic gear) that both magnets came loose inside the housing. No real happy with the newer B&S crap right now.

Sorted, un-tangled, and installed the wire harness. I had to pull some pins out of plugs to fully untangle. Also installed 5' of new fuel line.

I did a modification on the upper steering bushing as it was allowing side-to-side and up and down movement. I added an additional nylon bushing, and washer and nuts to the mounting bolts as these loosen up often. This thing is as tight and smooth as ever now.

I did a modification on the upper steering bushing as it was allowing side-to-side and up and down movement. I added an additional nylon bushing, and washer and nuts to the mounting bolts as these loosen up often. This thing is as tight and smooth as ever now.

Attachments

Last week I started cleaning and painting more Purple Sears parts so I can get it together.

Friday night I broke another tie rod on my everyday Sears, Saturday morning I removed both sides, cut some washers and welded all the balls back in and greased and re-installed. I really need to buy some new ones.

Today, I drug out an older riding mower I need to get started so we can have a decent mower. It's a Yard Machines hydrostatic 46" deck, it was a good mower when it ran, but I found it needs a starter and just going to replace coil as it was losing power last time it ran.

Also rebuilt carb on a Honda GXV walk behind I have this evening, had to spend $17 for a complete gasket kit when I needed one tiny specialized Oring on the idle circuit.

Wonderful mice infestation. Other side was solid leaves and fluffy stuff.

Friday night I broke another tie rod on my everyday Sears, Saturday morning I removed both sides, cut some washers and welded all the balls back in and greased and re-installed. I really need to buy some new ones.

Today, I drug out an older riding mower I need to get started so we can have a decent mower. It's a Yard Machines hydrostatic 46" deck, it was a good mower when it ran, but I found it needs a starter and just going to replace coil as it was losing power last time it ran.

Also rebuilt carb on a Honda GXV walk behind I have this evening, had to spend $17 for a complete gasket kit when I needed one tiny specialized Oring on the idle circuit.

Wonderful mice infestation. Other side was solid leaves and fluffy stuff.

No never on a mower deck, Noel. It's hard to say how it will hold up but I figured since I got enough to make 6 gallons I would try it. Only used about a pint. We use it at work on metal parts that are submerged in sewage and it holds up great year after year in that toxic, acidic and corrosive environment. I got these because the were past-date and were getting thrown in the garbage.Looks good Doug. Be interesting to see how it holds up. Have you used that before on decks.

Noel

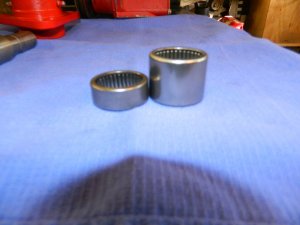

Worked on rebuilding two more deck spindles today. One had freshly been rebuilt late last year. Decided to let that epoxy coating cure another day on the deck. Got the old ones torn down, cleaned up the best housing, and drilled it for grease zirks. Then primed and painted it and got all the bearings and seals organized. About that time my wife needed some help on some stuff so it got put off for the rest of the day. Paint still tacky on the cleaned housing anyway.

Parts laid out.

The new roller bearings are twice as wide as the MF originals.

Drilled and painted housing.

DAC

speaking of wiring messes, I worked on my new to me 85 D 150 today, and I cannot believe that one wiring harness on one single truck can be so hacked and discombobulated. I stripped most of it away today, put a new old stock distributor in as the wiring to the original distributor had as much electrical tape as Ace Hardware just in that 4 inches that sticks out the housing..... the big, "hot" wire off the alt changed colors 3 times in about 16".... no crimp, no wire nut even.... fusible links stripped and wire just twisted and taped....I have worked on enough old Dodges over the years, none of the other wires to the coil, distributor, alternator field and such make any sense or are anywhere close to what they used to be.... or what the factory wiring diagrams say they should be....Sorted, un-tangled, and installed the wire harness. I had to pull some pins out of plugs to fully untangle. Also installed 5' of new fuel line.

I did a modification on the upper steering bushing as it was allowing side-to-side and up and down movement. I added an additional nylon bushing, and washer and nuts to the mounting bolts as these loosen up often. This thing is as tight and smooth as ever now.

I gutted it, put a standalone "high performance" Jacobs ignition setup onto it taht's been collecting dust in my attic for years, to find out it was NFG..... bought it years ago for another one of my vehicles that I no longer have..…. but it was used, then.....

so I found a couple of engine wiring harnesses I had from 70s trucks, also collecting dust, these are factory harnesses/stripped the tape wrap and gutted just the electronic ignition portion of one of them, and tossed the rest of the left overs..... gonna put that on here as a "test" just to hear this engine run long enough to warm it up and test oil pressure, etc...….. got 2 wires left to connect one to a "+" hot with the key, and the other to a "+" hot in "start" or "crank" and I should have fire.

and pirated a factory electronic ignition module off my kid's 440 motorhome engine/ that I know ran when pulled, and stashed in my garage..... if he don't come for said 440 soon, it is becoming awfully tempting to drop said 440 into this truck...…

took tomorrow off work, gonna hit the local junkyard in the morning, something I usually cant do when I go to work during teh week....

my wife has a Dr appt to hopefully get released back to work (see how much good being released to work will do here given this virus BS..... )

and I took off work to go with her.... its right near noon,

also today I went out to the storage barn, was out there for the 1st time this year a few days ago/ as the kid needed my "parts" deck for the New Holland, and discovered then, that the spare roof for my Apache popup camper had fallen from where I had it stored with 2X6s within slats across the corn crib.... it had only been there 2-1/2 years.... I "had" it well strapped down, though last year I had to adjust the straps a few times over last summer.... the previous year it hadn't budged a bit, but now it was crashed to the ground..... so I went out there before messing with my truck, with my Sawzall and Coleman Pulse 1850 generator and cut up that camper top...….I had stripped out 2 of them a few years ago, sold both roofs from the part-outs, this one had come off of one that "my" roof that I sold had gone onto, it had some cracks from a limb having fallen onto it but it "was" fixable til it fell almost 10 feet...… so hopefully now mine don't get damaged...…they haven't made these campers since the mid 80s.

don't look like I'll get to actually USE that camper this year with all that is going on with this virus.....most campgrounds are closed down. I had planned on going to a few tractor shows and camping nearby while they were going on/ but tractor shows cancelled too..... blahh

I used to be a yacht mechanic in fla. I once had to prep a large swordfish for delivery and install some electronics for the buyer. Brand new boat mind you. (Brand withheld to protect the company). Took out the dc panel and found that every single wire was green! Not corrosion, but green nylon insulation!!!speaking of wiring messes, I worked on my new to me 85 D 150 today, and I cannot believe that one wiring harness on one single truck can be so hacked and discombobulated. I stripped most of it away today, put a new old stock distributor in as the wiring to the original distributor had as much electrical tape as Ace Hardware just in that 4 inches that sticks out the housing..... the big, "hot" wire off the alt changed colors 3 times in about 16".... no crimp, no wire nut even.... fusible links stripped and wire just twisted and taped....I have worked on enough old Dodges over the years, none of the other wires to the coil, distributor, alternator field and such make any sense or are anywhere close to what they used to be.... or what the factory wiring diagrams say they should be....

I gutted it, put a standalone "high performance" Jacobs ignition setup onto it taht's been collecting dust in my attic for years, to find out it was NFG..... bought it years ago for another one of my vehicles that I no longer have..…. but it was used, then.....

so I found a couple of engine wiring harnesses I had from 70s trucks, also collecting dust, these are factory harnesses/stripped the tape wrap and gutted just the electronic ignition portion of one of them, and tossed the rest of the left overs..... gonna put that on here as a "test" just to hear this engine run long enough to warm it up and test oil pressure, etc...….. got 2 wires left to connect one to a "+" hot with the key, and the other to a "+" hot in "start" or "crank" and I should have fire.

and pirated a factory electronic ignition module off my kid's 440 motorhome engine/ that I know ran when pulled, and stashed in my garage..... if he don't come for said 440 soon, it is becoming awfully tempting to drop said 440 into this truck...…

took tomorrow off work, gonna hit the local junkyard in the morning, something I usually cant do when I go to work during teh week....

my wife has a Dr appt to hopefully get released back to work (see how much good being released to work will do here given this virus BS..... )

and I took off work to go with her.... its right near noon,

also today I went out to the storage barn, was out there for the 1st time this year a few days ago/ as the kid needed my "parts" deck for the New Holland, and discovered then, that the spare roof for my Apache popup camper had fallen from where I had it stored with 2X6s within slats across the corn crib.... it had only been there 2-1/2 years.... I "had" it well strapped down, though last year I had to adjust the straps a few times over last summer.... the previous year it hadn't budged a bit, but now it was crashed to the ground..... so I went out there before messing with my truck, with my Sawzall and Coleman Pulse 1850 generator and cut up that camper top...….I had stripped out 2 of them a few years ago, sold both roofs from the part-outs, this one had come off of one that "my" roof that I sold had gone onto, it had some cracks from a limb having fallen onto it but it "was" fixable til it fell almost 10 feet...… so hopefully now mine don't get damaged...…they haven't made these campers since the mid 80s.

don't look like I'll get to actually USE that camper this year with all that is going on with this virus.....most campgrounds are closed down. I had planned on going to a few tractor shows and camping nearby while they were going on/ but tractor shows cancelled too..... blahh

Cut out the cab corner and welded the new one in on the 99 ranger. This was a major pain. Went super slow. Measure. Cut. Fit. And repeat until it fit. Took my time welding. Tack. Move a few inches. Tack..move. wait a bit. Repeat. I bet I spent an hour welding. Trying to keep it cool to prevent warping. I probably went over kill on that step but it looks perfect.

Going to work on a couple small dents. Then start prepping for paint. Paint came in last week. Midnight blue base coat with a high shine clear coat.

Never painted a car before...painted plenty of tractors with single stage. Going to be a learning experience. Going for a 5 foot paint job. Anything will look better than the baked stock paint.

Hard to believe this truck is 21 years old. Had only one rust spot on the entire truck. Body is still perfectly straight. Its spent all of its life sitting outside. Several years of its life it sat in the same spot and never moved.

Not bad for a ford

Going to work on a couple small dents. Then start prepping for paint. Paint came in last week. Midnight blue base coat with a high shine clear coat.

Never painted a car before...painted plenty of tractors with single stage. Going to be a learning experience. Going for a 5 foot paint job. Anything will look better than the baked stock paint.

Hard to believe this truck is 21 years old. Had only one rust spot on the entire truck. Body is still perfectly straight. Its spent all of its life sitting outside. Several years of its life it sat in the same spot and never moved.

Not bad for a ford

Mines a 2005 ranger Aaron and the box is gone bad. And I would say that every box on a ranger in eastern Canada is the same. I’ve been looking for a good box and none in this area. A few business in eastern Canada go to Texas and buy rust free boxes and resell them here. I’m not sure what I’m gunna do with mine. My box dropped last year and I did a temporary fix.

Noel

Noel

Last edited: