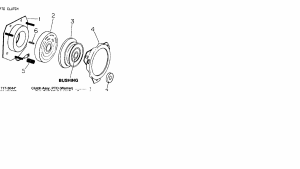

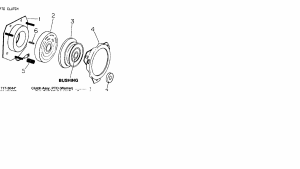

I think I stumbled on the problem. There was 2 different models of clutches. The difference is parts are not interchangeable though they look the same. There is 0.100' difference in the length of the large part of the bushing. One is 0.795 and the other is 0.785. Overall length is the same. Will dign into this later this morning. Also need to figure out what part is supposed to do the moving in these things.

Last edited: