There's no turning back now. Pulled the distributor, generator, starter, fan, and water pump to get to get them out of the way. Then went after the cylinder assemblies.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Workin' on the Old Tractors

- Thread starter cjet69

- Start date

Removed the radiator, hydraulic system, fuel tank, and front end. Just the crankcase is left. Supposed to rain tomorrow so I may not get the crankcase removed.

Attachments

-

100_6656-m.JPG310.4 KB · Views: 13

100_6656-m.JPG310.4 KB · Views: 13 -

100_6657-m.JPG304.8 KB · Views: 13

100_6657-m.JPG304.8 KB · Views: 13 -

100_6658-m.JPG294.1 KB · Views: 9

100_6658-m.JPG294.1 KB · Views: 9 -

100_6659-m.JPG286.8 KB · Views: 10

100_6659-m.JPG286.8 KB · Views: 10 -

100_6660-m.JPG305.8 KB · Views: 10

100_6660-m.JPG305.8 KB · Views: 10 -

100_6661-m.JPG323.6 KB · Views: 10

100_6661-m.JPG323.6 KB · Views: 10 -

100_6662-m.JPG304.9 KB · Views: 9

100_6662-m.JPG304.9 KB · Views: 9 -

100_6663-m.JPG302.8 KB · Views: 9

100_6663-m.JPG302.8 KB · Views: 9 -

100_6665-m.JPG261.3 KB · Views: 9

100_6665-m.JPG261.3 KB · Views: 9 -

100_6666-m.JPG279.7 KB · Views: 13

100_6666-m.JPG279.7 KB · Views: 13

Cjet.. The morning you got up and decided to go dig out that tractor do you ever think maybe I should have thought of something else to do that day...Removed the radiator, hydraulic system, fuel tank, and front end. Just the crankcase is left. Supposed to rain tomorrow so I may not get the crankcase removed.

With the wear that it has I could see just throwing bearings in it and hoping. My brother verified that at least one rod is out of round and will need resizing.Looks like it’s a good thing that you’re tearing it all the way down.

When I bought it 20 yrs ago I assumed that this would need to be done to it. I also like this type of work, just don't like the $$$$ end of it.Cjet.. The morning you got up and decided to go dig out that tractor do you ever think maybe I should have thought of something else to do that day...

Got the crankcase pulled and removed the cam and crank. I think all that remains is the governor and oil pump. We'll see if I can get the spare crankcase and front end bolted on tomorrow so I can roll it out of here.

Attachments

-

100_6672-m.JPG296.9 KB · Views: 10

100_6672-m.JPG296.9 KB · Views: 10 -

100_6674-m.JPG255.3 KB · Views: 9

100_6674-m.JPG255.3 KB · Views: 9 -

100_6675-m.JPG264.3 KB · Views: 7

100_6675-m.JPG264.3 KB · Views: 7 -

100_6676-m.JPG316.8 KB · Views: 7

100_6676-m.JPG316.8 KB · Views: 7 -

100_6677-m.JPG288.1 KB · Views: 7

100_6677-m.JPG288.1 KB · Views: 7 -

100_6679-m.JPG275 KB · Views: 7

100_6679-m.JPG275 KB · Views: 7 -

100_6680-m.JPG262.4 KB · Views: 7

100_6680-m.JPG262.4 KB · Views: 7 -

100_6683-m.JPG296.7 KB · Views: 7

100_6683-m.JPG296.7 KB · Views: 7 -

100_6684-m.JPG274.8 KB · Views: 8

100_6684-m.JPG274.8 KB · Views: 8 -

100_6685-m.JPG270.6 KB · Views: 10

100_6685-m.JPG270.6 KB · Views: 10

Bolted the ZAN back together. Had to put the radiator back on to keep water out of the steering gear while it sits. Added some sheet metal to help shed water. Now to find a good spot to park it.

Attachments

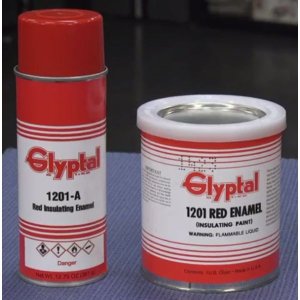

Must be all of the lead and other hazardous materials that make it hold up so well.I like the idea of the cam having caps to hold it in place, CJet! Pretty unusual idea I think. The internal paint in this engine still looks like new!

DAC

Last edited:

Lead based paint was far superior to the stuff nowadays, at least in the sign industry. Better adhesion, opacity and long term durability. I still have a 50# bucket of Dutch Boy white lead from the 1930's or '40's. I liked the can. When I left a 80-year-old sign shop I worked at in the early 1980's one of my ex-coworkers swiped that bucket of white lead and brought it to the shop I had. Je said he remembered how cool I thought the bucket was---LOL!

Even Rustoleum had some good spray paints in the 1970's far as using like MM did inside engine blocks. I worked at a racecar shop from 1973-1975. We would de-burr the inside of engine blocks, polish them up a bit with a die grinder and put them through a cleaning process in a hot tank. Get them out has was with a steam cleaner while hot and dry them off with compressed air. Mask off the machined surfaces and paint the internals with Rustoleum Fire Hydrant Red. I still have one engine block still in service in my '72 GMC that was prepped back then. Last time I had that engine opened up was back in 2015 and the paint was stained but still intact! The engine builder back then said the internal paint would seal in microscopic sand from the casting process that was imbedded in the pores of the cast iron. Engine still runs well. Nowadays I would imagine the casting process is much cleaner.

DAC

Even Rustoleum had some good spray paints in the 1970's far as using like MM did inside engine blocks. I worked at a racecar shop from 1973-1975. We would de-burr the inside of engine blocks, polish them up a bit with a die grinder and put them through a cleaning process in a hot tank. Get them out has was with a steam cleaner while hot and dry them off with compressed air. Mask off the machined surfaces and paint the internals with Rustoleum Fire Hydrant Red. I still have one engine block still in service in my '72 GMC that was prepped back then. Last time I had that engine opened up was back in 2015 and the paint was stained but still intact! The engine builder back then said the internal paint would seal in microscopic sand from the casting process that was imbedded in the pores of the cast iron. Engine still runs well. Nowadays I would imagine the casting process is much cleaner.

DAC

With it raining I did some inside work. Filled the rust pits and a couple small dents in the MM ZAU replacement fuel tank. and got it all sanded down. I'll try to get it hung up and primed tomorrow.

Attachments

-

100_6713-m.JPG137.3 KB · Views: 7

100_6713-m.JPG137.3 KB · Views: 7 -

100_6715-m.JPG148.9 KB · Views: 7

100_6715-m.JPG148.9 KB · Views: 7 -

100_6716-m.JPG138.1 KB · Views: 6

100_6716-m.JPG138.1 KB · Views: 6 -

100_6720-m.JPG146.5 KB · Views: 6

100_6720-m.JPG146.5 KB · Views: 6 -

100_6721-m.JPG140.2 KB · Views: 6

100_6721-m.JPG140.2 KB · Views: 6 -

100_6722-m.JPG162.5 KB · Views: 6

100_6722-m.JPG162.5 KB · Views: 6 -

100_6723-m.JPG143.5 KB · Views: 6

100_6723-m.JPG143.5 KB · Views: 6 -

100_6724-m.JPG144.7 KB · Views: 6

100_6724-m.JPG144.7 KB · Views: 6 -

100_6725-m.JPG143 KB · Views: 7

100_6725-m.JPG143 KB · Views: 7

Nice work, CJet! You are an old pro at these restos! Those look like some great infra-red heat lamps! I had a couple years ago but they both got broken. Main use was to dry paint in my shop when I was sign painting. One was shorted out in my well house when I had it out there during a blizzard and the thaw from the storm happened so fast it flooded the well house and fried the light! The other one got knocked over and the tubes shattered.

DAC

DAC

Yep, over 20 yrs in the autobody trade. Now I do mostly my own stuff and just a few side jobs.

I picked this up last year from Vevor. One bulb was broken during shipping and they sent me a replacement but I haven't installed it yet. I occasionally need to paint something when its really cold out in the shop and figured one of these lamps would do the trick. Thought this would be better than stoking up a fire and running the propane heater for half of the day to warm the whole shop up in order to paint.

I picked this up last year from Vevor. One bulb was broken during shipping and they sent me a replacement but I haven't installed it yet. I occasionally need to paint something when its really cold out in the shop and figured one of these lamps would do the trick. Thought this would be better than stoking up a fire and running the propane heater for half of the day to warm the whole shop up in order to paint.

Can't remember if I have ever posted these old pics. I think I would be around 14/15 yrs old in these pics of the Farmall H with the manure spreader. The old barns still had chicken manure in them even though they had hadn't been used for chickens in 20/25 yrs by that time. Guessing this was in late 70's.

Attachments

Are we that thin and have that much hair today Cjet ?Can't remember if I have ever posted these old pics. I think I would be around 14/15 yrs old in these pics of the Farmall H with the manure spreader. The old barns still had chicken manure in them even though they had hadn't been used for chickens in 20/25 yrs by that time. Guessing this was in late 70's.

That H looked pretty nice. Hand crank too !

Still pretty thin with a little bit more of a belly but not too bad. The hair is gray and keeps sliding off the back. Right now I need a hair cut cause its kinda like a Mullet but rather than being "Business in the front, Party in the back", its more like "Charlie Brown in the front and Not invited to the party in back".Are we that thin and have that much hair today Cjet ?

That H looked pretty nice. Hand crank too !

Dad had just painted the tractor back then and hadn't fixed the starter yet. It never had a dead battery back in those days either.

My father in-law had both an H and M with loaders and narrow front ends. I had to bail off of both when they tipped over. One when lifting the back of a 5 bottom plow and the other I was driving across our snow covered yard and ran over something under the snow with one rear tire. Thankfully I was young and fast and ended up with nothing worse than some bad bruising. I do not like narrow front ends with loaders.